Properties of metals play a very important role when choosing materials for a specific project. The choice of materials is mostly between aluminum alloy and stainless steel, each having different attributes in order to suit certain applications and conditions. This blog will be focusing on the differences within these steels regarding strength levels, composition, and their various applications, among a few other noteworthy factors.

Understanding Aluminum Alloy and Stainless Steel

Before dealing with the analysis of these material differences, it is good to understand the basic composition of each substance. Aluminum and steel stand out as metals, with varying levels of strength and diverse uses.

Composition and Properties of Aluminum Alloy

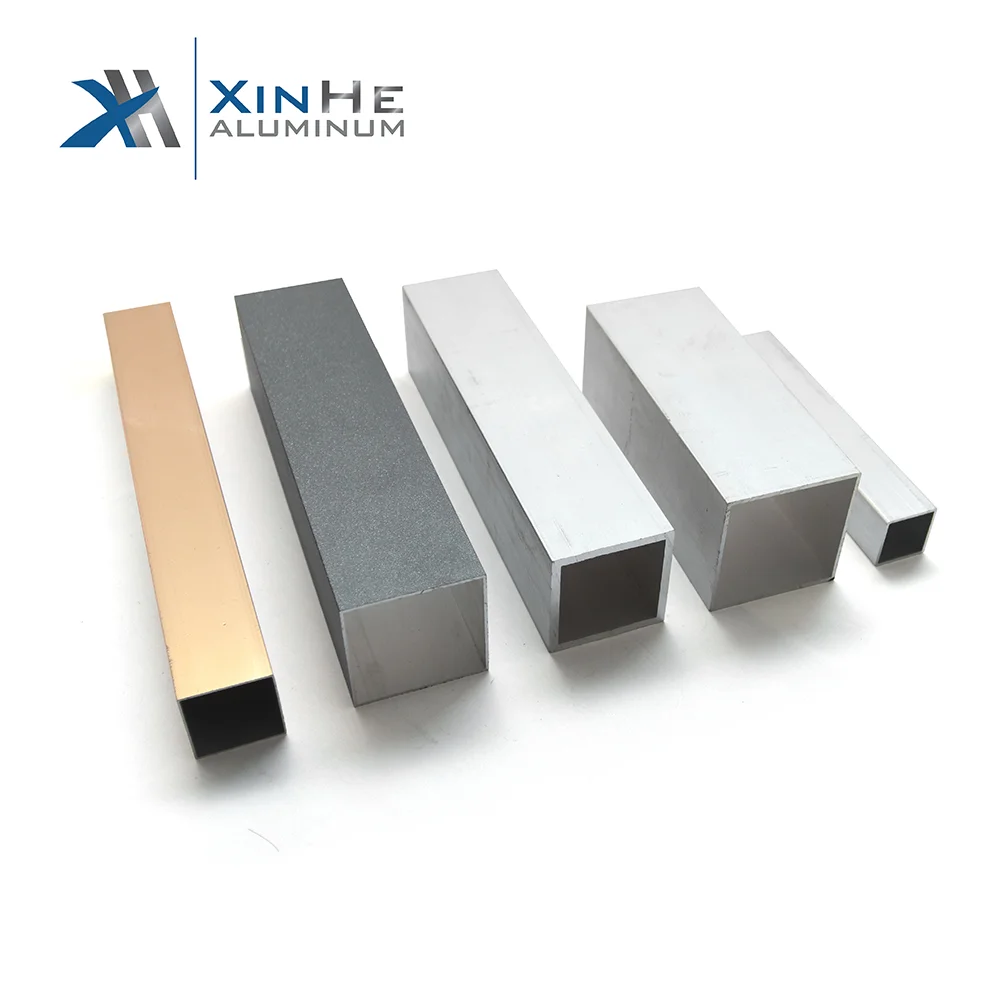

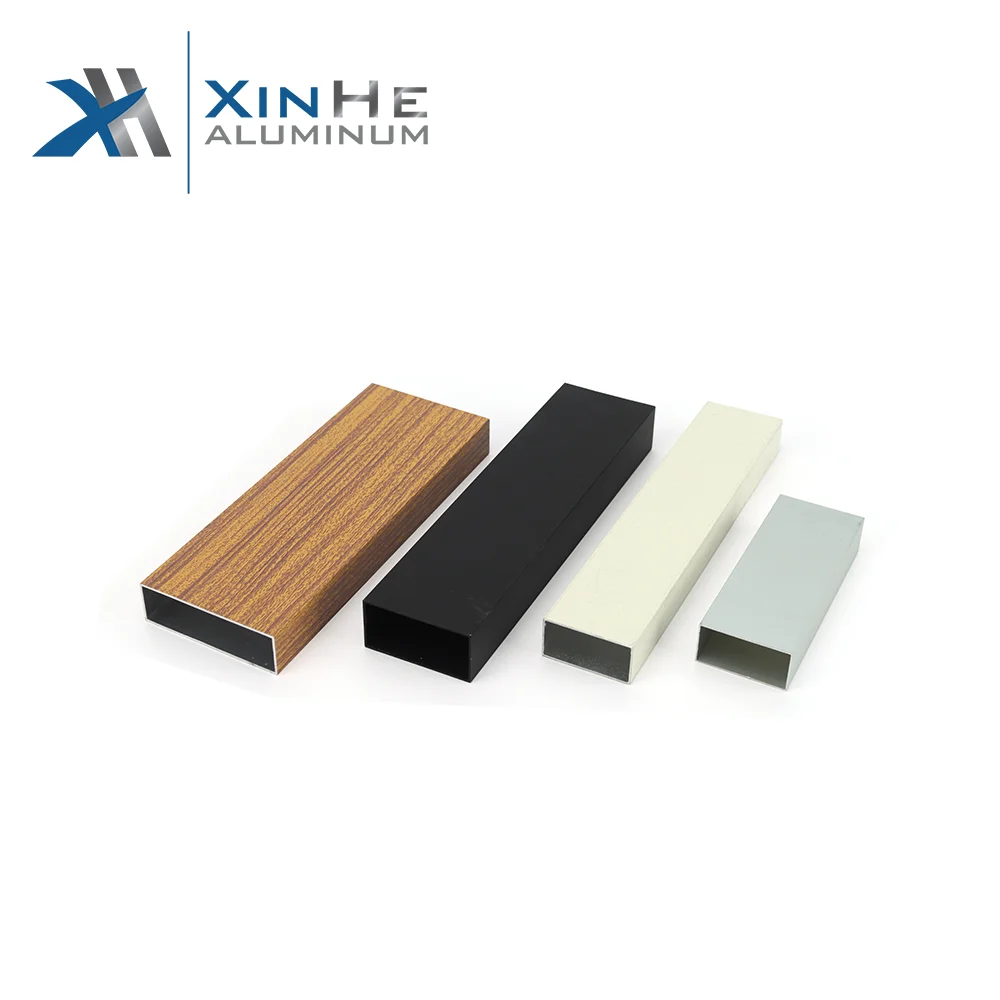

The aluminum alloy includes such elements as copper and magnesium addition to improve properties. Industrial profiles of aluminum can be referred to as a category of alloying material, having aluminum as a component and addition elements such as silicon, zinc, and so on to increase some characteristics of the material. These alloys enjoy excellent properties regarding strength, which is combined with light weight, corrosion resistance, and thermal conductivity.

Composition and Properties of Stainless Steel

Stainless steel represents a group of iron alloys which always contain chromium, and they sometimes contain the elements nickel and molybdenum. It is mainly the chromium in steel that provides resistance to corrosion through the formation of a thin layer of chromium oxide.

Comparison of Strength: Aluminum Alloy Versus Stainless Steel

It can be determined by the resistance or strength that a material shows to tensile strength and impacts, among others. These would be very important factors in comparing and contrasting the strengths of aluminum with stainless steel in terms of durability.

Tensile Strength Analysis

Tensile strength is defined as the stress a material can undergo before breakdown when the material is being stretched. In most cases, stainless steel has a higher tensile strength than its alloys of aluminum, making stainless steel a choice. However, aluminum alloys can be modified to possess tensile strengths by utilizing particular alloying and heat treatment techniques.

Yield Strength Considerations

Yield strength is the point at which a material starts to deform under conditions of stress and strain. It is usually observed that stainless steel has a yield strength compared to aluminum alloys, which means the former resists higher amounts of stress before permanent deformation occurs.

Impact Resistance Test

It is resistance to the absorption of energy during the process of deformation. This is the ability of stainless steels to resist impact loads without fracture, but some of the aluminum alloys also show reasonable impact resistance because of their ductility. The normal choice between these materials depends upon the differing conditions of impact they will receive during operation.

Application of Aluminium Alloy and Stainless Steel

Aluminum alloy and stainless steel are preferred for certain applications because they possess properties which make them superior to others as evidenced by their various uses in many fields.

Industrial Applications of Aluminum Alloys

Aluminum alloys find various applications in a wide range of industries because they possess desirable characteristics like lightweight and anti-corrosion. Generally speaking, the industrial aluminum profile refers to all kinds of aluminum profiles used in the industries except for building doors and windows, curtain walls, interior and exterior decorations, and building structures. Frame aluminum profiles for various parts and components are considered industrial aluminum profiles. They are also applied to aircraft structure construction in the aerospace industry for their high strength-to-weight ratio. In the industry, they help improve fuel efficiency by making the vehicle lighter. In consumer electronics, aluminum alloys are also used in casings and heat dissipaters.

Applications of Stainless Steel

Stainless steel is valued worldwide for its strength and the ability to avoid corrosion in both construction and car industries, tools for medical treatments, and the food industry related to kitchen machines or food treatment facilities. That it has great aesthetic appeal with stability under extremely adverse conditions easily makes it first choice for structural uses such as railings, cladding paneling, even in chemical processes that involve heavy destruction.

Material Selection Factors

In selection of materials for your project, such factors are considered to determine whether an aluminum alloy or a stainless steel is best.

Weight Considerations in Design

Weight is another factor that should be considered in material selection for design purposes. Aluminum alloys are preferred over steel because of their lighter weight, which makes them popular in industries like aerospace and automotive. Due to the lightweight property of aluminum alloys, handling and transporting them proves easier, which is beneficial in projects and constructing structures that need minimal load-bearing capacity.

Corrosion Resistance Differences

Corrosion resistance is one of the factors that determine the choice of materials to apply in different areas. Stainless steel is unique due to its resistance to corrosion, caused by the chromium content that forms a protective oxide layer on its surface. This quality makes stainless steel an option for environments exposed to moisture and corrosive elements. On the other hand, aluminum alloys also exhibit good resistance to corrosion, mainly with additional protective coatings or anodized. The industrial profiles in aluminum are light, nice-looking, and easy to assemble and disassemble on production lines after anodizing treatment for corrosion resistance and durability in various uses.

Cost Implications for Projects

In any project, decisions consider the cost of alternatives that lie between the two material options, namely aluminum alloy and stainless steel. By and large, the former tends to be cheaper compared to steel. The lighter weight of aluminum results in reduced material expenses per unit volume and potential savings on transportation costs due to its characteristics. That said, the cost of aluminum products can still vary based on the alloy mix and any extra treatments applied.

Advancements in Material Technology

Aluminum alloy and stainless steel continue to progress as material technology advances.

Innovations in Aluminum Alloy Production

Recent progress in material technology has allowed rapid development in the manufacturing processes of aluminum alloys, which is mainly aimed at improving mechanical properties with the object of extending their use areas. Special combinations of alloy ingredients with appropriate thermal treatment techniques result in a higher strength-to-weight ratio and allow superior performance under extreme environmental conditions. Such reasons constituted the base for increased use of these materials in different industry segments.

Recent Trends in Stainless Steel Production

The production of steel has also witnessed significant progress in enhancing its characteristics and expanding its application possibilities. Innovative manufacturing methods have emerged to bolster the strength, flexibility, and rust resistance of steel to higher levels. These advancements guarantee that stainless steel continues to be an option for challenging tasks that demand top-notch materials.

Xihui Aluminium: Your Reliable Partner

Founded in 1993, boasting three decades of expertise in the field of aluminum extrusion profiles is Foshan Xihui Aluminium Co., Ltd., known for its top-notch products and ultra-thin materials. With a lineup of 15 automated extrusion lines and a range of production setups at their disposal, they specialize in crafting aluminum profiles tailored for different purposes such as doors and windows, kitchen cabinetry, as well as industrial and architectural applications. They also provide ODM and OEM services to cater to customer requirements through personalized design, manufacturing, and packaging. Xihui stands out as a source for aluminum alloy items.

FAQs

Here are a few common questions that can assist in enhancing your comprehension of aluminum alloy and stainless steel:

1. Which one is the better material that can be used outdoors?

Aluminum and stainless steel will both be adequate for applications concerning their ability to resist corrosion well.

2. Can Aluminum alloy and Stainless Steel be used together in any project?

Yes, but with the knowledge of the fact that if they fall into scenarios with galvanic corrosion, they can corrode aluminum at relatively fast rates.

3. How does the strength-to-weight ratio of aluminum alloy compare to that of stainless steel?

Generally, aluminum has the best strength-to-weight ratio compared with stainless steel.