Aluminum extrusion stands out as a favored manufacturing method employed to craft a diverse array of products in various shapes and sizes with precision and specificity in mind. The technique entails the pushing of aluminum alloy through a mold to shape a seamless profile continuously. One pivotal aspect in the realm of aluminum extrusion revolves around the choice of aluminum alloy grade selection because distinct alloys present differing characteristics that can significantly influence the ultimate performance of the end product.

In this blog post, we will explore the top aluminum grades for extrusion along, with their characteristics and typical uses. Additionally, we will introduce Xihui Factory as a supplier of aluminum extrusions and showcase its strengths and benefits.

Understanding Aluminum Extrusion Alloys

Aluminum alloys come in series numbers like 1XXX to 7XXX, with each series having its special features designed for specific uses; for extrusion needs, commonly used alloy series are 1XXX, 3XXX, 6XXX, and 7XXX.

1XXX Series Aluminum

The series includes aluminum for commercial use with 1050 aluminum as a well-known illustration of this type of material. Despite providing resistance to corrosion being easy to work with and conducting electricity well, the alloys in the 1XXX series have lower strength than other grades. They are typically utilized in situations where high strength is not a primary requirement, like in food trays and reflective surfaces.

3XXX Series Aluminum

The 3000 series of aluminum alloys are known for their ability to be shaped and their resistance to corrosion, which makes them ideal for applications needing a moderate level of strength, such as fuel tanks and piping, chemical equipment, and truck and trailer components.

6XXX Series Aluminum

The 6XXX series stands out as a choice for aluminum extrusion due to its impressive mix of characteristics in terms of strength and versatility in applications both structural and non-structural.

6061 Aluminum is a metal that is commonly used as a replacement for mild steel because of its moderate to high strength levels and its ability to be welded easily with good surface finishing properties. It is utilized in various industries for making building materials, automotive components, pipes, furniture, and bike frames.

6063 Aluminum is highly regarded for its surface finish and affordability along with being easy to extrude, making it a preferred material for delicate designs and complex shapes. Its ability to weld well and resist corrosion makes it ideal for applications such as window frames, door frames, outdoor furniture, electrical parts, and piping systems.

Aluminum Alloy 6005 A is known for its strength and superb ability to be extruded smoothly into hollow or open shapes, for design purposes where toughness matters most when treated with various tempers like -T1, -T5, and -T61 options.

7XXX Series Aluminum

The 7XXX series of aluminum alloys, including 7075 aluminum, is renowned for its strength and excellent strength-to-weight ratio; however, these alloys have limited formability and weldability characteristics that can complicate the extrusion process. These challenges notwithstanding, the 7XXX series alloys remain in demand for applications that demand superior strength, such as aircraft parts, missile components, and gear mechanisms.

Factors to Consider When Choosing an Aluminum Extrusion Alloy

Choosing the kind of aluminum alloy for extrusion requires taking into account a range of factors that can impact how well the end product performs and functions.

Strength: The necessary strength of the item plays a key role in the selection process. For tasks that require strength, alloys belonging to the 2XXX or 7XXX series could be a good fit. On the other hand, when moderate strength suffices, it may be worth exploring alloys from the 3XXX and 6XXX series.

The ability to be shaped easily is determined by the formability of the alloy when it is being extruded into shapes and structures. The 1XXX series, 3XXX series, and 5XXX series alloys are known for their formability characteristics.

When the extruded item is going to be in places with lots of corrosion around, it’s important to pick an alloy that can stand up to it enough. Like the 5XXX series with a highlight on 5052 aluminum, which holds its own against corrosion.

Heat Treatment Capability. Certain types of metal mixtures can undergo a heat treatment process to improve their characteristics and performance levels. The 2XXX series well, as the 6XXX and 7XXX series of alloys are examples of materials that can be heat treated to customize the properties of the end product.

Welding Consideration: When it comes to welding, product attentiveness should be given to choosing an alloy with favorable weldability characteristics is crucially essential in the process. A general observation is that the 3XXX and 6XXX series alloys typically demonstrate weldability properties.

Machinability: The ease with which an alloy can be machined can impact production costs and efficiency. Alloys from the 2XXX and 6XXX series generally possess good machinability.

Price: The pricing of aluminum alloys may differ greatly, so it’s crucial to take into account both budget limitations and the necessary characteristics when selecting an alloy.

Aluminum Extrusion Tempers

Aluminum tempers are vital, for improving the characteristics of extruded items by undergoing specific heat treatments or mechanical procedures that change the alloy’s microstructure and consequently impact its strength and ductility levels significantly. Common aluminum extrusion tempers encompass:

T1: Cooled down after being heated and left to age naturally.

T2: Cooled down from a temperature and then subjected to cold working before naturally aging over time post-processing.

T3: After subjecting it to heat treatment and cold working processes, is allowed to age.

T4: Solution heat-treated and naturally aged.

T51:After being cooled down from a temperature and stretched to relieve stress, it was then artificially aged.

T6: Solution heat-treated and artificially aged.

T61: Solution heat-treated and artificially aged.

Introducing Xihui Factory: A Reliable Aluminum Extrusion Supplier

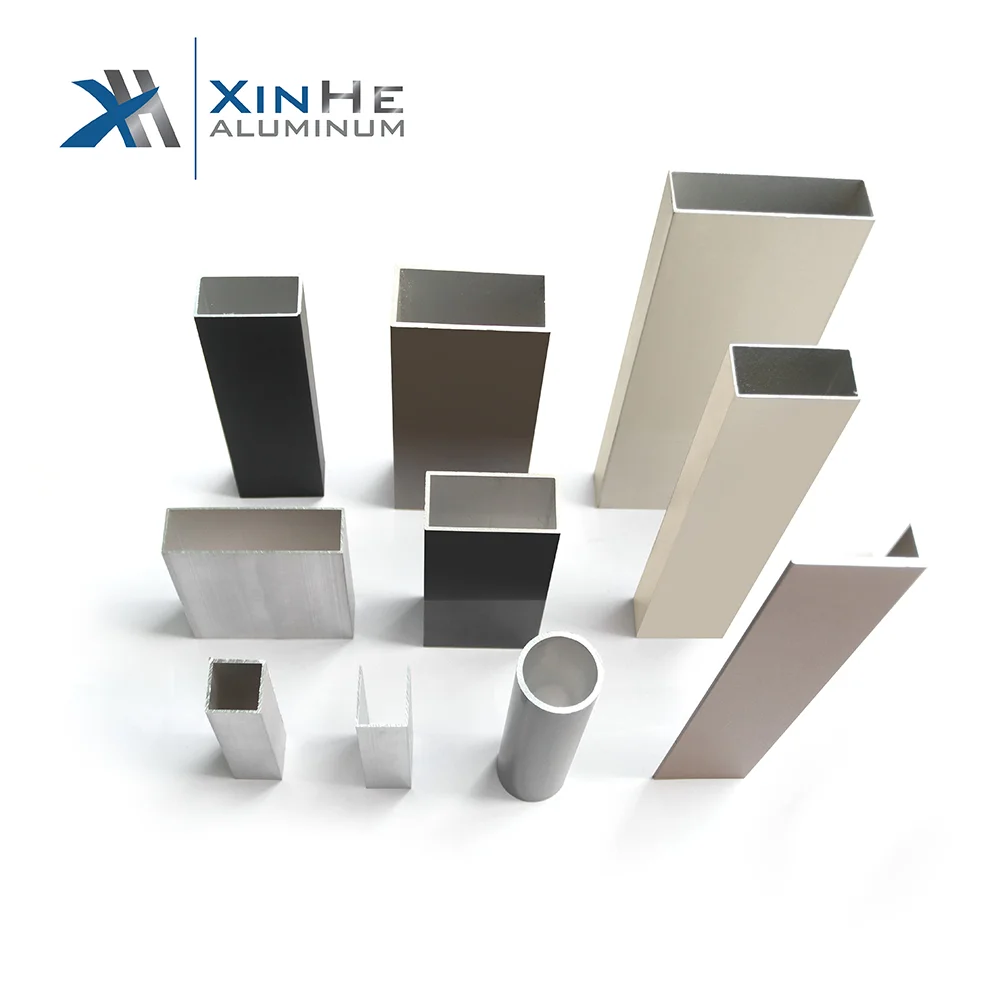

The Xihui Factory in Foshan, China, is a known supplier of aluminum extrusion products with more than three decades of industry experience under its belt. The company focuses on crafting top-notch aluminum extrusion profiles. Provides an extensive selection of items such as V Slot Aluminium Extrusions For Structural Framing, across various industries and uses.

Why Choose Xihui Factory?

With over 30 years in the aluminum extrusion industry, Xihui has gained expertise and insight to provide top-notch products and services.

Xihui has a production capability, with 15 aluminum extrusion machines and 40 deep processing machines that allow them to manage big orders and fulfill various customization needs.

Xihui offers custom aluminum extrusion solutions through their OEM and ODM services by working with clients to meet their unique requirements and preferences.

Stringent Quality Control: Xihui maintains quality control procedures during production to guarantee that all items adhere to top-tier quality standards consistently upheld by their committed QC team through meticulous inspections, for customer contentment.

Xihui focuses on streamlining production and logistics to guarantee delivery times ranging from 7 to 15 days.

Xihuis products are available in more than 120 countries worldwide, and they have successfully carried out over 10k engineering projects, which highlights their dedication to serving customers globally and their proficiency in managing intricate and challenging tasks.

Competitive Pricing: Xihui provides pricing while maintaining top-notch quality as a source manufacturer, with extensive production capabilities.

Xihui offers a selection of aluminum profiles, including those for windows and doors, kitchen cabinets, tile trims, curtain blinds, awnings, ceiling diffusers, and industrial and construction applications.

Xihui offers a range of services that cover design work, manufacturing processes, surface finishing techniques, and assembly services.

Conclusion

Selecting the aluminum grade for extrusion is vital to attaining the intended product performance and functionality goals successfully. When deciding on an alloy for this purpose, factors like the strength level it offers, formability ability, resistance to corrosion, and cost considerations should all be taken into account. Xihui Factory stands out as a supplier of aluminum extrusions, providing a wide array of products and services to meet diverse needs while prioritizing customer satisfaction with their focus on quality, efficiency, and innovative solutions.