To accurately identify different types of aluminum profiles, it is essential to familiarize oneself with their characteristics and applications. In various sectors such as construction and manufacturing, aluminum profiles play a vital role in creating durable, attractive, and functional products. Understanding the nuances of aluminum profile types can improve decision-making regarding material selection, design, and overall functionality. This knowledge not only assists in ensuring structural integrity but also enhances aesthetic appeal, contributing to the overall success of projects. This article will delve into methods to identify aluminum profile types accurately, highlighting the key aspects that differentiate them.

Understanding Aluminum Profile Types

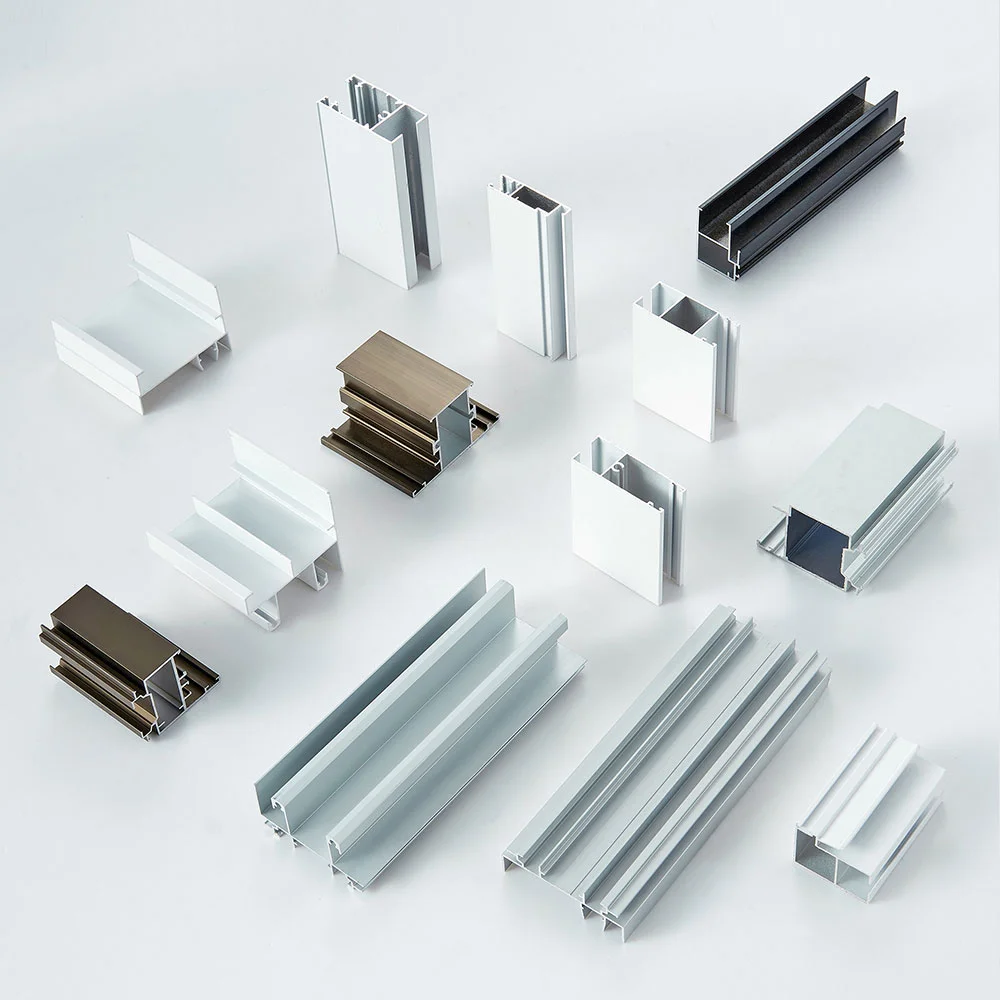

Aluminum profiles come in various shapes and sizes, catering to different applications and performance requirements. Each type boasts unique characteristics influencing its suitability for specific uses. Common types include extruded profiles, rolled profiles, and fabricated profiles, each serving distinct purposes in construction, manufacturing, and design. For instance, extruded profiles are widely used in window and door frames, while fabricated profiles find applications in specialized structural components. Gaining a thorough understanding of these profiles allows experts in the field to select the right type for their projects effectively.

Overview of Common Aluminum Profiles

In the world of aluminum profiles, several common varieties emerge. Extruded profiles can be characterized by their cross-sectional shapes, which can range from simple rectangles to complex custom designs. Rolled profiles, on the other hand, are typically available in thinner gauges and are used in applications requiring high strength-to-weight ratios, such as structural reinforcements. Fabricated profiles involve multiple processing steps, often combining welding, bending, and machining to create intricate shapes that meet specific structural needs. Each type of profile carries its own advantages and limitations, making it critical for experts to identify them correctly to optimize their use in various applications.

Key Characteristics of Different Profiles

When distinguishing between aluminum profiles, certain key characteristics help in accurate identification. These include the profile’s dimensions, weight, and surface treatments. For example, extruded profiles usually have rigid dimensions and tend to be heavier due to their solid construction, making them preferable for structural applications. In contrast, rolled profiles are lighter and often feature smoother surfaces, which can be ideal for architectural elements requiring a refined finish. The surface treatment applied, such as anodizing or powder coating, can also significantly influence the profile’s appearance and resilience to environmental factors, adding another layer of differentiation among types.

Visual Identification Techniques

Visual identification techniques can aid significantly in determining the type of aluminum profile used in a product or application. Observing surface finishes, shapes, and dimensions can provide instant clues about the profile type. Noticing the nuances in these attributes can enhance an expert’s ability to ensure accurate identification and application.

Surface Finish Analysis

The surface finish is one of the most telling aspects when identifying aluminum profiles. Various finishing techniques like anodizing, powder coating, and electrophoresis lead to different appearances and textures. Anodized surfaces may exhibit a metallic gleam, while powder-coated surfaces tend to have a more uniform matte finish. Additionally, treatments such as wood grain transfer can provide aesthetic versatility, making aluminum profiles appear more traditional. Evaluating the surface finish not only helps distinguish between profile types but also indicates their potential longevity and resistance to wear over time.

Shape and Dimensions Assessment

The shape and dimensions of aluminum profiles are vital identifiers. Common shapes encompass channels, angles, and available flat bars, each serving unique functions in construction and manufacturing. By measuring these dimensions and analyzing the geometry, experts can accurately identify the profile type in question. For instance, a narrow, elongated profile may suggest a specific application like window framing, while a more robust profile could be intended for structural reinforcement. Paying close attention to these details ensures optimal material selection for various engineering and architectural demands.

In the ever-evolving landscape of aluminum profiles, Xihui stands out as an expert manufacturer providing a diverse array of aluminum products tailored for various applications. Committed to innovation and quality, Xihui specializes in designing and manufacturing customized aluminum profiles that cater to the unique requirements of its clients. With offerings that include aluminum windows, doors, and various architectural components, Xihui consistently meets the high standards expected by professionals in the field. Their extensive experience allows them to deliver products with distinct characteristics like superior strength, aesthetic appeal, and a range of surface treatments, ensuring that each profile is suited for its specific application. By leveraging state-of-the-art manufacturing techniques and a well-researched approach to design, Xihui effectively combines functionality and artistry in its aluminum solutions. Partnering with Xihui means choosing a reliable source for premium aluminum profiles that continuously enhance properties such as durability and adaptability, meeting the diverse needs of the modern construction landscape.

In conclusion, identifying aluminum profile types accurately involves understanding their unique characteristics and employing effective visual identification techniques. By recognizing the differences in surface treatments, dimensions, and shapes, experts can ensure that the right aluminum profiles are chosen for various applications, enhancing project outcomes and sustainability. With manufacturers like Xihui leading the way in offering superior products, the market is well-equipped to cater to the diverse demands of architectural and structural applications. And xihui home after-sales is very guaranteed, and online customer service is 24 hours a day.

Physical Testing Methods

Tensile Strength Testing

Tensile strength testing is an essential method for identifying aluminum profile types, as it evaluates how much stretching a material can withstand before breaking. This characteristic is vital for determining the suitability of an aluminum profile for specific applications, especially in construction and structural components. During tensile testing, samples of the aluminum profiles are subjected to gradual stress until they deform or fracture. The resulting data shows the maximum load the profile can bear, which can then be compared against industry standards for various aluminum grades. For example, a profile that maintains its integrity under high tensile stress is likely to be of higher strength alloy, making it feasible for load-bearing applications.

Moreover, tensile strength values not only facilitate the selection of appropriate profile types but also ensure that the materials can endure operational stresses in real-world applications. By analyzing results from tensile tests, professionals can make informed decisions about which aluminum profiles to use in specific designs, ultimately optimizing performance. Understanding the tensile properties can also influence the design process itself, as engineers might choose a specific profile type to match the mechanical requirements, ensuring long-term durability.

Hardness Verification

Hardness verification is another critical physical testing method used for accurately identifying aluminum profile types. This process measures the material’s resistance to localized plastic deformation, which provides insights into the alloy’s strength and durability. Various hardness testing methods exist, including Brinell, Rockwell, and Vickers tests, each suited for different applications and materials. For aluminum profiles, the Rockwell test is commonly employed because it is quick and offers direct readings for softer materials like aluminum.

The hardness of an aluminum profile influences its ability to withstand wear, corrosion, and environmental factors, making it a significant identifier when selecting materials for specific applications. For instance, profiles that exhibit higher hardness levels may be more suitable for outdoor constructions exposed to harsh weather conditions or frequent use. Additionally, understanding the hardness of different aluminum alloys helps professionals predict the profile’s performance and longevity in practical applications, which is crucial for maintaining structural integrity and aesthetic appeal over time.

By utilizing these physical testing methods, industry experts can more accurately identify and select aluminum profile types tailored to their specific applications, enriching both the functionality and design of the products they create. Through precise tensile strength and hardness evaluations, professionals ensure that their material choices contribute positively to the overall success of their construction or manufacturing projects. Leveraging such testing enables more informed decisions, leading to better resource allocation and enhanced performance in engineered solutions.