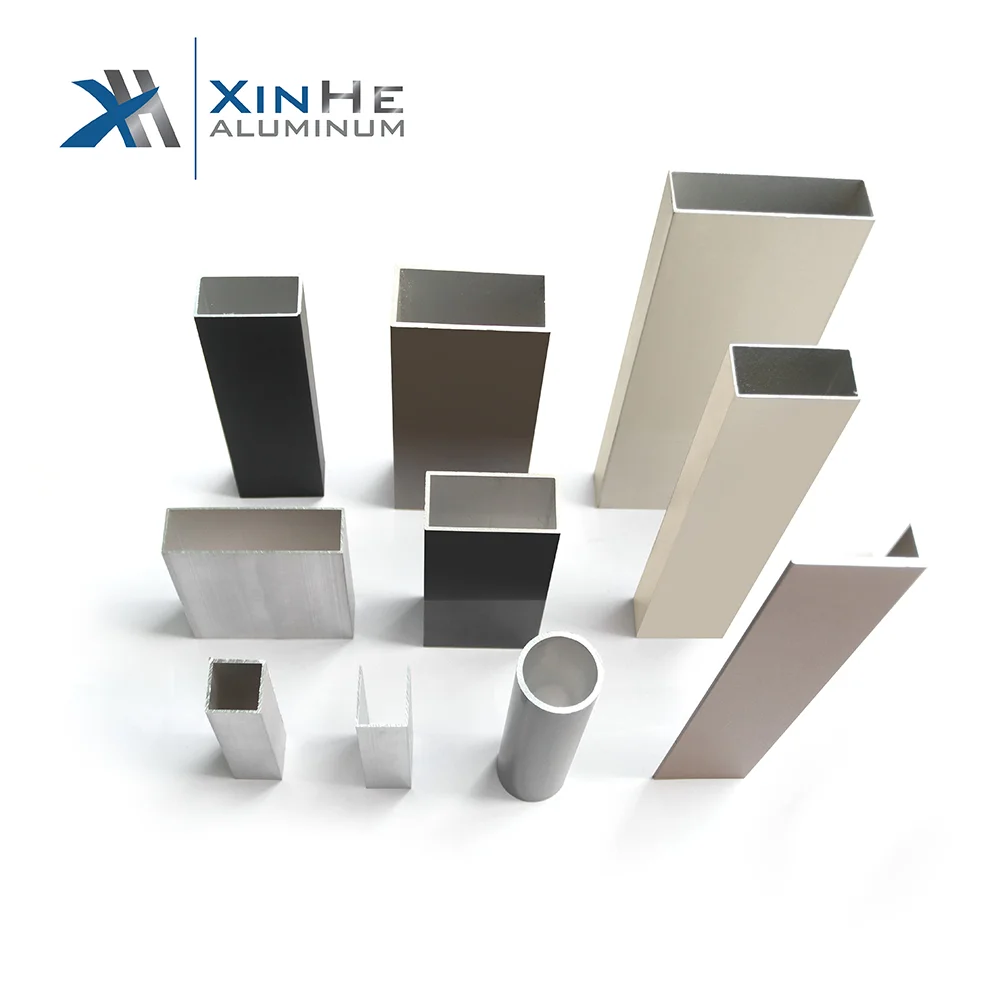

The world of aluminum extrusion continues to evolve, meeting the demands for high-quality, versatile solutions for modern engineering projects. At the forefront of this innovation are CNC-machined aluminum enclosures—a perfect example of craftsmanship meeting cutting-edge technology. When precision and durability matter the most, these enclosures deliver optimum performance while showcasing sophisticated aesthetics.

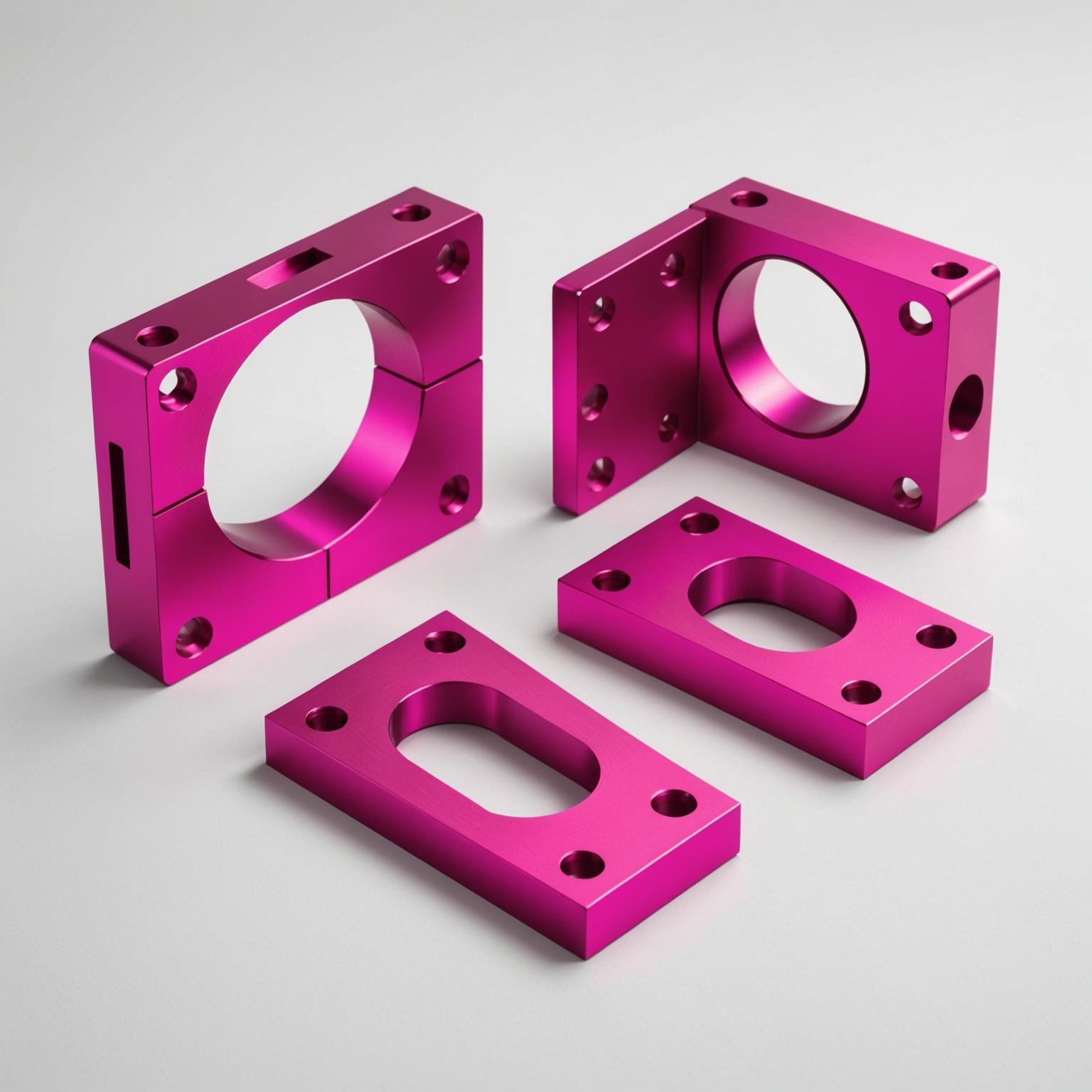

Aluminum extrusion CNC machining allows manufacturers to achieve unparalleled accuracy in producing components designed for a variety of applications. Whether you’re an industrial designer or a tech enthusiast, these enclosures cater to both functionality and style. Crafted from high-grade aluminum, these products undergo meticulous CNC machining to ensure a flawless finish and structural integrity. The process allows for consistent quality across units, making them reliable for electronics, industrial designs, and custom projects. Enhanced with anodized finishes such as vibrant magenta, sleek blue, and elegant gold, they combine visual appeal with durability, creating corrosion-resistant surfaces that retain their brilliance over time.

An aluminum extrusion manufacturer focuses not just on durability, but also on adaptability and versatility. The CNC-machined aluminum enclosures come in various shapes and sizes, accommodating a wide range of electronic components, connectors, and designs. The carefully crafted apertures ensure seamless integration of ports and connectors, making them the ideal solution for personal gadgets, IoT devices, and professional electronics. Additionally, advanced features such as heat dissipation properties and robust construction make these enclosures suitable for demanding environments, providing protection against environmental factors while promoting optimal performance.

In addition to their practical capabilities, these aluminum enclosures exude a sense of luxury and style, making them a popular choice for consumer electronics and limited-edition products. The magenta variant, for example, appeals to those seeking bold, standout aesthetics, while the blue and gold options bring sophistication and elegance to professional or high-end settings. Moreover, personalization options such as custom engraving and precision finishing enable users to showcase their brand identity or add a unique touch to their designs. This makes these CNC-machined aluminum enclosures not only functional but also a canvas for creativity and artistic expression.

From prototyping consumer electronics to creating enclosures for automotive and aerospace applications, these CNC-manufactured aluminum products represent a perfect blend of precision, artistry, and eco-conscious design. Aluminum is a sustainable and recyclable material, making it a responsible choice for manufacturers who prioritize environmental impact without compromising quality or performance. With their durable construction, striking anodized finishes, and versatile design architecture, these enclosures redefine the concept of modern engineering and technological innovation.

In conclusion, CNC-machined aluminum extrusion enclosures are more than just hardware—they are a reflection of how technology and design can work together to create solutions that are both practical and visually compelling. Whether you’re looking to protect your electronics or make a statement with sleek aesthetics, these enclosures offer unmatched quality and adaptability. Embrace this advancement in manufacturing technology and transform your vision into reality with aluminum enclosures that lead the way in precision, durability, and style.