Understanding Aluminum Profile Rust Resistance

Contrary to steel and its susceptibility to rust, aluminum profiles are distinguished by their remarkable rust resistance. Their particular resistance to corrosion can be attributed to their unique composition, which is defined as a type of metal that is non-ferrous and contains specific alloys. In addition, due to a perfect balance between elements within the product, or its density, this metal offers an optimal combination of weight and strength. At the same time, aluminum profiles retain some of their most valuable qualities, such as a tendency to resist environmental impacts that may lead to the development of rust. Finally, appropriate treatment and finishing guarantee that it is possible to use these products under harsher conditions with premature corrosion.

The Composition of Aluminum

Obviously, the main component in aluminum profiles is aluminum, often alloyed with magnesium, silicon, and zinc. Different share of alloying elements improves mechanical properties, offer better resistance to corrosion, and improve other properties in general. For instance, magnesium makes the material more weldable and strong, while silicon improves castability. Also, this diversified alloying makes metal more versatile and suitable for more applications, particularly, where rust resistance is vital. Do not forget that aluminum is appreciated due to its lightweight, which is vital in modern construction and design.

Protective Oxide Layer

When ferrous metals come into contact with atmospheric oxygen, the products of combustion and corrosion formed are referred to as “rust.” However, the type and behavior of the rust varies depending on the actual composition of the ferrous metal, as well as the substances with which it comes into contact. Different types of steel and iron will have varying rust compositions, which behave differently. Suppliers often coat or treat ferrous parts to create a tarnish-resistant finish that is less prone to harm. A few examples include electropolishing, passivating, pickling, coating with a layer of solvent or oil, phosphating, and applying a lacquer or sealant. Conversely, ferrous metals will still corrode and tarnish.

Manufacturing Techniques that Enhance Rust Resistance

Different advanced production techniques are used by manufacturers, such as Xihui’s, to ensure that resistance to rust is well maximized in the aluminum profiles. With the effective use of these techniques, Xihui ensures that there are maximum quality and durability delivered by its aluminum profiles. The first of these processes is extrusion, where Xihui uses the process to come up with profiles in different shapes and sizes throughout their length and still make sure that they are rigid. The resultant aluminum profiles are free-rust and are not only strong but also very lightweight.

Extrusion Process in Xihui’s Production

One of the main reasons for the top quality and high performance of Xihui’s aluminum profiles is a well-thought extrusion process. The latter implies squeezing molten aluminum through a mold to create the desired shapes. As a result, the surface is distinguished by its smoothness and uniformity, thus being primed to different kinds of treatment aimed at increased corrosion resistance. The company ensures the compliance of its profiles with the most stringent quality expectations by employing advanced technologies and automated systems at the extrusion stage. The process is indispensable for creating high-performance aluminum profiles capable of resisting almost any weather conditions, thus being applicable in the long-term perspective.

Surface Treatments Employed by Xihui

In addition to the rust-proof effect, Xihui applies several surface treatment methods to further improve the rust resistance of the aluminum profiles. This not only provides additional protection but also can be used to customize the appearance, so customers can choose any treatment to match the look they want to achieve for their projects.

Anodizing Process

The process most widely used by Xihui and which distinguishes the company is anodizing. The industrial process uses electrolytic solutions in which the aluminum profiles are immersed. When they pass an electric current, they develop a thicker and denser oxide layer, which endows the profiles with superior corrosion resistance. Although the profiles can be anodized in a range of colors for decorative purposes, another characteristic is that the anodized surface is 60-300 on the Vickers hardness scale. That is harder than the original aluminum and grants the profiles improved scratch and abrasion resistance. Finally, these two features make the anodized profiles especially suitable for outside applications, such as window and door profiles, by helping prevent potential decorations and colors from easily peeling off in inclement weather conditions.

Powder Coating

In addition to anodizing, Xihui employs the technique of powder coating, which presupposes a process of application of dry powder to the surface of aluminum and its curing through heat. Such an approach not only increases the protection of the material against corrosion but also results in a bright and strong finish that can be adjusted to suit decorating demands. As a result, a thicker protective layer is created, ensuring that the powder firmly sticks to the surface of the aluminum and does not come off even in the long run. The availability of a range of colors allows the customers to choose the one they consider to be most appropriate and track the changes in understanding aluminum.

Heat Treatment Procedures

Firstly, Xihui applies heat treatment techniques during the production of aluminum profiles. It involves heating aluminum to predefined temperatures and then rapidly cooling it. The effect of this industrial procedure is the mechanical properties of the metal. In other words, the treatment enhances the strength of the aluminum, making it less sensitive to stress and less susceptible to mechanical damage, which may result in corrosion. This approach proves to be useful for aluminum profiles designed for tough environments because they become more rugged.

Environmental Factors Affecting Aluminum Profile Durability

The durability of aluminum profiles can also be influenced by environmental factors. Understanding these factors allows manufacturers like Xihui to optimize their products for various applications and conditions.

Corrosion Resistance in Various Climates

It is well-known that aluminum profiles possess outstanding resistance to corrosion whatever the climate in question might be. At the same time, such external factors as humidity, salinity, and temperature can still affect the long-term performance of materials. Therefore, in coastal areas, where saltwater contact is likely to remain common, aluminum profiles adjust with enhanced surface coatings or anodization to protect against potential corrosion. In its turn, Xihui’s choice of materials and treatments serves to demonstrate the company’s cognizance of the issue as a means to ensure their aluminum profiles can be used in a number of settings.

Industrial Applications and Exposure

Moreover, industrial applications can present more challenges affecting the durability of aluminum profiles. First, the presence of chemicals and pollutants may result in a corrosive effect if appropriate measures are not taken in time. Xihui offers a wide range of aluminum profiles with designs and finishes aimed at withstanding such conditions. Thus, the products are suitable for a wide range of industrial applications, including materials to be used in production facilities, transportation systems, and other areas. In conclusion, it should be noted that the combination of innovative design solutions and adherence to the strong attention to critical details such as chemical resistance and other characteristics in the production processes makes Xihui one of the few reliable suppliers of aluminum profiles that are capable of bearing the heavy load of industrial applications.

To sum it up, Xihui’s dedication to improving the mastery of each element involved in the rust resistance of aluminum profiles within an innovative process and treatment gestures towards a product that meets the parameters of the given industry. Having a solid grip on the sewing and design of different aluminum products, their abilities, surface treatment methods, and the issues of the environment, Xihui has set the quality for durability and appeal in their manufacturing, making sure that their aluminum profiles stay an architects and builder’s top choice.

Advantages of Choosing Xihui’s Aluminum Profiles for Rust Prevention

If you need to select aluminum profiles characterized by a strong resistance to rust, your decision to select Xihui as your provider is reasonable. The products in question are designed from the best materials and through the use of innovative processes that have one single aim the prevention of corrosion. What Xihui implements is a uniform measure of quality control at every stage of profile production. Not only can you expect rust-resistant profiles but also durable products that do not corrode because of the proximity of such environmental factors as humidity and pollution.

Quality Control Measures at Xihui

Xihui’s commitment to quality is evident from the very start of the manufacturing process, as the company selects high-quality aluminum alloys proven to be resistant to corrosion. In addition, Xihui employs rigorous inspections and tests at all stages of the manufacturing process. We can conclude that Xihui’s products meet all of the established standards and performance benchmarks as they are subjected to rigorous quality control checks necessitated at the procurement stage, production process, and acceptance phase. These checks establish the tensile strength, identify defects on the surface of the profiles, and determine resistance to damage of protective coatings. Therefore, the application of advanced methods in the sphere of quality assurance ensures that aluminum profiles manufactured by Xihui will work reliably and will not rust.

Longevity and Maintenance Benefits

The long-lasting aluminum profiles that Xihui provides allow various maintenance advantages for those who use them. The presence of protective oxide or other coating layers means that corrosion would either not happen or be decelerated over the long term. Long durability automatically lessens the need for repair or replacement, creating lower maintenance costs. Continuation of good appearance is another benefit related to long durability due to protective measures. Finally, there is peace of mind for the customers who are aware that the product is long-lasting and easy to use. For all these reasons, the clients would benefit from the use of Xihui’s aluminum profiles.

Selecting the Right Aluminum Profile for Your Application

To choose a good aluminum profile, it is necessary to consider the task the material is needed for. Xihui offers various aluminum profiles, providing multiple variants according to every use, and meets every project with appropriate solutions in terms of rust prevention and reliability. The provider has both standard and customized versions, which makes it better than others.

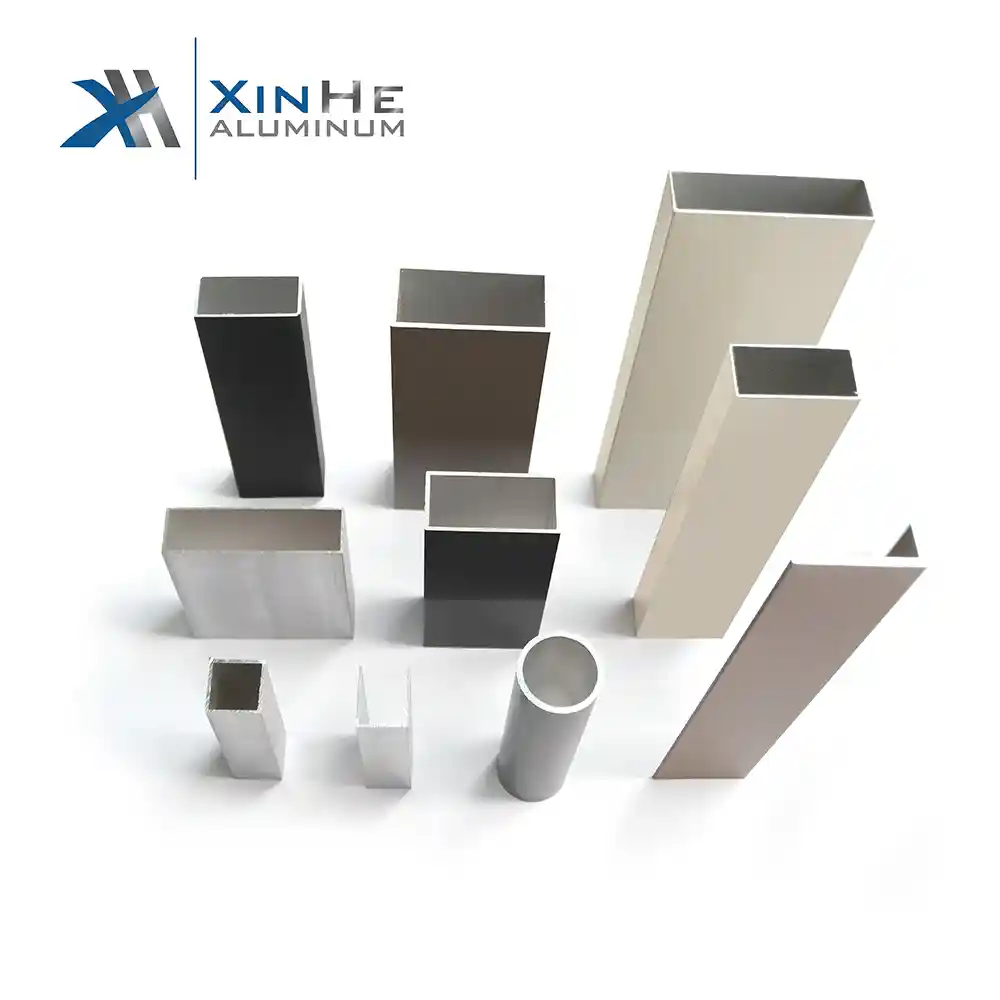

Xihui’s Range of Products

Standard Profiles

Xihui’s standard profiles are suited for diverse applications. They offer a choice of profiles suitable for window frames, door frames, and all other structural uses where corrosion resistance is a concern. Easy to use for a variety of applications, Xihui’s profiles can be incorporated into designs without compromising on performance. All of these products are produced to the highest standards of quality, ensuring that architects and builders can rely on their durability and appearance.

Custom Solutions

Xihui provides not only standard but also custom solutions designed to meet the individual needs of a particular project. Clients can convey their ideas regarding a complex profile design or provide specific requirements concerning profile parameters. In any case, the company ensures that any environmental challenges and expectations regarding profile design, as well as the overall situation, are thoroughly met. To a large extent, this is made possible by the manufacturability of Xihui’s production, allowing a higher level for adaptability, which is particularly important in the context of contemporary design specifications and trends.

Factors to Consider When Choosing

There are several points that one should pay attention to when selecting an aluminum profile for any purpose. The first point is the evaluation of the conditions of the environment in which the profile will stay. It is necessary to learn what elements will be present, including humidity, salinity, and temperature, as they affect the long-term influence on aluminum profiles.

Another significant factor is the purpose the profile is used for. Different applications might require different strength and durability, thus the variety of profiles Xihui offers is a great advantage. Moreover, we have to consider possible aesthetic requirements, since the looks and finish play a large role in making an aluminum profile not just functional but an interesting design solution.

Lastly, clients must critically assess whether any surface treatments, such as anodizing or powder coating, will be adequate for increased corrosion resistance. With their wealth of knowledge regarding these factors, Xihui learned to expertly advise clients to make an educated decision. As a result, they guarantee that the appropriate choice will be both efficient and trustworthy for each of your projects.

In conclusion, it can be stated that Xihui is outstanding for manufacturing fine-quality aluminum profiles and comprehending the requirements of its clients. Highly friendly customer service, new manufacturing technologies, and solid product collection make this company the leader among rustproof aluminum profile producers. Thus, this partner is suitable for architects, builders, and manufacturers.