Efficiency is given the topmost priority in CNC machining, yet cutting the cost is more than just making it happen. By applying high-tech machinery, optimum material selection, and highly skilled workforces, manufacturers can significantly reduce costs and increase productivity. This blog will help you learn how to make your CNC machining operations leaner and more profitable in the long run.

Why Is Process Optimization Important for Cost Efficiency in CNC Machining?

Cost efficiency is a vital goal for CNC machining manufacturers. By optimizing and enhancing various aspects of the CNC machining process, you can reduce costs significantly without compromising or even improving the quality of the final product.

Reduction in Material Waste

Process optimization in CNC machining reduces material waste. Planning reduces waste and errors through reduction, saving raw material and minimizing cutting waste disposal. Efficient cutting paths and tool usage maximize the utilization of materials, and costs are minimized.

Improved Machine Utilization

Simplify operations and remove bottlenecks by optimizing processes for better CNC machine utilization. Reduce idle time, increase productive time, and lower per-unit cost of production. Better scheduling and resource allocation are some of the most important strategies.

Lower Labor Expenses

Optimization of CNC processes can lower labor expenses by minimizing manual intervention. Automation reduces human error, which improves quality output. Training employees on optimized processes improves productivity and cost savings.

How Does Workflow Streamlining Improve CNC Machining Savings?

Streamlining workflows in CNC machining is another efficient method to improve savings. By optimizing each step of the manufacturing process, you can eliminate inefficiencies and enhance overall productivity.

Elimination of Duplicate Steps

Simplified workflows eliminate duplicate machining operations, simplifying operations and reducing their duration. This translates to faster project turnaround, facilitating increased work without increasing expenses. Simpler workflows eliminate irregularities or delays.

Faster Production Cycles

Simplified workflows enhance production speed and productivity, allowing more to be made in a shorter duration without increased expense. This benefits customers and improves market competitiveness.

Increased Tool Path Efficiency

Optimization of tool paths enhances process workflow through streamlined paths during machining, reduced tool wear, prolonged machinery life, and uninterrupted high-quality output. This means lower production time and lower energy consumption.

What is the Role of Technology in Improving CNC Processes?

The application of advanced technology has a central role in enhancing CNC processes in cost-effectiveness.

Implementation of Sophisticated Software

Sophisticated software packages maximize CNC machining. They provide functionality such as simulation to validate situations prior to production, detecting problems early on to prevent additional costs or time delays.

Integration of Automation Systems

Automation systems are being integrated with CNC machining operations to take efficiency to an even higher level. Automated systems deal with repetitive operations with precision and consistency, enabling human resources to be diverted to more complex operations. Integrating automation reduces the cost of labor while ensuring that the operations go on impeccably around the clock if needed.

Real-Time Monitoring Capabilities

Real-time monitoring of CNC machining gives insight into the operations in real time. Real-time access to information allows quick detection of performance deviations or potential issues so that immediate corrective action can be taken to reduce disruption and optimize production during manufacturing.

By embracing such technological advancements with process improvement efforts like workflow optimization and machine utilization optimization described above—manufacturers are poised not only to achieve significant cost reductions but keep ahead of the competitive edge in today’s fast-paced marketplace!

How Does Material Selection Affect Cost-Effective CNC Machining?

Selecting the right material is a crucial factor in achieving economical CNC machining. Material selection can influence the overall cost in addition to the efficiency of the machining process.

Balancing Cost and Performance

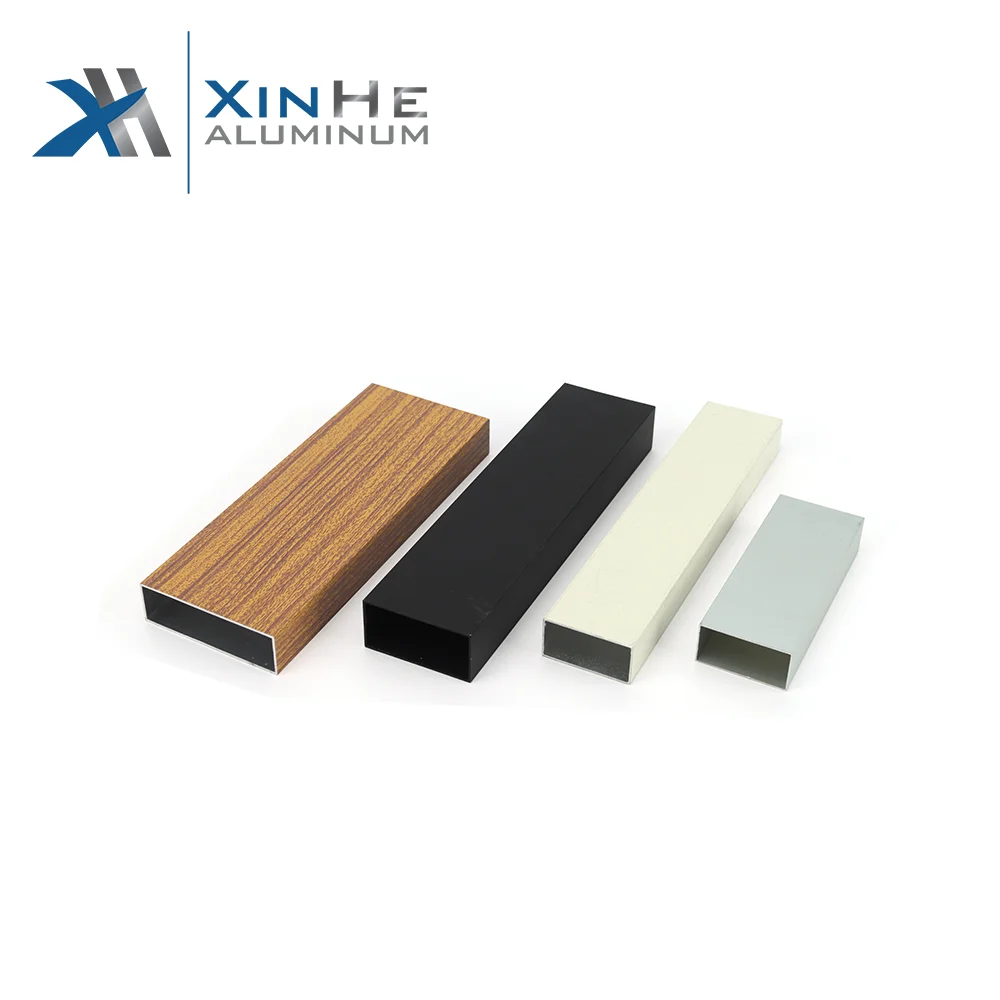

Selection of CNC machining material involves compromise between cost and performance. Low-cost materials sacrifice quality or longevity, while high-performance materials deliver strength and lifespan for a higher price. Aluminum alloys are in high demand for being light in weight and corrosion-proof, suited to most applications for a slightly greater expense. Consider project requirements in order to choose materials suitable within budget and performance requirements.

Adaptability for Specific Processes

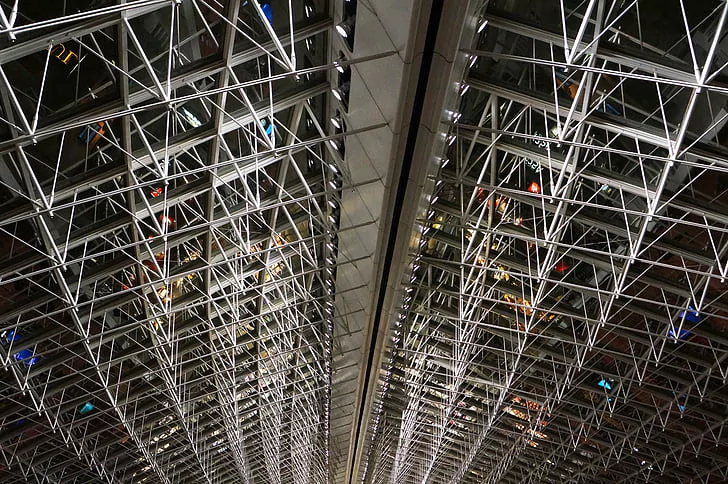

Material CNC-friendliness is of great importance. Materials like Aluminum T-Slot Profiles, which are soft and therefore simple to machine, influence the efficiency of milling, drilling, or turning. Material behavior understanding optimizes processes, reduces tool wear, and optimizes production cost.

Reducing Scrap Through Precision

Precision in CNC machining ensures high-quality outputs and minimizes scrap. With Aluminum Industrial Profile and the same material content, exact cutting is provided to prevent errors and material wastage. Precision maximizes material utilization and minimizes disposal cost.

Can Employee Training Enhance Process Optimization Results?

Employee training becomes a core function to enhance process optimization results for CNC machining. Trained personnel are more effective in using optimized processes.

Building Skills to Ensure Precision

Investment in employee skill training ensures workers work on CNC machines with precision. Specialized training enhances the precision of operations, leading to better product quality and reduced errors. Trained workers possess efficient work habits.

Error Reduction Techniques

Error reduction training ensures employees detect issues prior to being expensive mistakes. Understanding CNC machining errors allows operators to prevent error, reducing downtime and ensuring consistent quality.

Efficient Problem-Solving Skills

Effective problem-solving abilities empower workers to act rapidly. Training in CNC repair enables employees to correct problems with no downtime for production, enabling more efficient operating and maximum process optimization.

Imbuing yourself with these concepts as part of your strategy when dealing with materials and employee development will certainly net great dividends toward optimizing costs associated with your CNC machining operations!

How XiHui Aluminium Co., Ltd Assist You?

XiHui Aluminium Co., Ltd excels in the aluminium industry, making high-quality aluminium profiles and CNC machining. They have a high-tech anodizing and powder coating lines at their state-of-the-art factory that make the products highly durable and aesthetically pleasing. From A-grade aluminium, they provide eco-friendly, long-lasting solutions. XiHui ODM & OEM services include design, production, packaging, and shipping, which are advantageous for construction contractors, window/door manufacturers, and wholesalers. Cooperation with XiHui enhances operational efficiency and competitiveness through their experience and end-to-end support.

FAQs

Q: Can close tolerances increase CNC machining costs?

A: Yes, tighter tolerances mean higher-accuracy machining, additional operations, and higher inspection costs, adding to the cost.

Q: What are the advantages of batch production in CNC machining?

A: Batch production spreads the cost of setup over more units, benefits from economies of scale, and reduces the unit cost.

Q: Are lean manufacturing concepts transferable to CNC machining?

A: Indeed, lean practices eliminate waste, reduce workflows, and increase efficiency, directly promoting cost savings.