When considering the weight-bearing capability of aluminum extrusions it is crucial to grasp the factors involved in choosing the material for your project. Alloy composition, heat treatment, design geometry, and environmental circumstances all play a role, in determining the load capacity of aluminum extrusions. In this article we will delve into the elements that affect the strength and longevity of aluminum extrusions explain how load capacity is determined and discuss uses in sectors such as construction, automotive manufacturing, and aerospace engineering. Whether you are creating frameworks or making high-quality components for applications having a good grasp of these aspects can greatly contribute to the durability and safety of your extrusions.

What Factors Influence the Load-Bearing Capacity of Aluminum Extrusion?

When thinking about the weight that aluminum extrusion can support or bear securely in place? It’s important to grasp the aspects that impact its ability to hold up weight effectively and sturdily.?Aluminum extrusion is a material utilized in many different scenarios. However, the level of its toughness and robustness is influenced by various essential factors.

Material Properties of Aluminum

The characteristics of aluminum material are crucial in defining how much load extrusions can bear with factors, like alloy composition and heat treatment methods having an impact.

– Alloy Composition

Aluminum alloys are formed by mixing aluminum with elements to improve features like strength and resistance to corrosion and make it easier to work with metal materials. The type of alloy chosen plays a role in determining the traits of the extruded material . For example, some alloys are tailored for applications requiring strength making them perfect for bearing loads.

– Heat Treatment Processes

Heat treatment methods are employed to modify the mechanical characteristics of aluminum alloy. This can improve their strength and hardness levels hence boosting the load-bearing ability of aluminum extrusions. Choosing the heat treatment method plays a role in maximizing the performance of extrusions in various applications.

Design and Geometry of the Extrusion

The arrangement and shape of an aluminum extrusion play a role in its capacity to support weight considering aspects such as the sectional form and thickness of the walls.

– Cross-Sectional Shape

The overall form of an extrusion plays a role in its strength and capacity to evenly spread out loads across it with intricate shapes supported by points offering more robustness than basic shapes do. It is crucial for the design to be customized to suit the needs of the intended use all while ensuring that the load is distributed optimally.

– Wall Thickness and Reinforcements

The thickness of the wall is also crucial in deciding how much weight it can bear effectively. Thicker walls typically provide strength and stability which helps the extrusion handle loads. Moreover, if reinforcements are added to the design it can improve the extrusion’s capacity to support loads by offering support where necessary.

Environmental Conditions

Changes in the environment also play a role in affecting how well aluminum extrusions hold up under pressure and over time taking into account things like changes in temperature and exposure to substances when determining the load-bearing capacity.

– Temperature Variations

Changes in the characteristics of aluminum can be influenced by fluctuations in temperature levels. Environmental conditions at the extremes might cause the metal to expand or contract resulting in repercussions on the stability of structures. It is crucial to grasp how temperature changes can affect the performance of your particular use case in order to uphold peak efficiency.

– Exposure to Corrosive Elements

Aluminum extrusions need to be resistant to corrosion when facing conditions outdoors as prolonged exposure to elements can weaken the material and decrease its ability to bear loads effectively. Selecting alloys that resist corrosion well and using coatings can help counter these consequences.

How is the Load Capacity of Aluminum Extrusion Calculated?

Determining the weight-bearing limit of aluminum extrusions requires a mix of computations and sophisticated simulation methods to guarantee precision and dependability.

Theoretical Calculations and Formulas

Studying calculations forms the basis for comprehending the behavior of aluminum extrusions under pressure by analyzing stress-strain relationships and load distribution patterns.

– Stress-Strain Relationships

Through an examination of stress-strain connections one can anticipate the reaction of an extrusion to pressures by gauging stress levels under loads to ascertain its ultimate load-bearing capabilities without malfunctioning.

– Load Distribution Analysis

Analyzing load distribution involves studying how forces move through the structure of an extrusion to pinpoint any vulnerabilities or spots that may need strengthening for performance in situations.

Simulation and Modeling Techniques

Sophisticated simulation methods such as Finite Element Analysis (FEAs) along with the use of Computer-Aided Design (CAD) allow for the modeling of structures in real-world scenarios.

– Finite Element Analysis (FEA)

Finite Element Analysis (FEI) is a tool widely employed in engineering disciplines to examine structures under different loads or constraints. By replicating real-world situations through models engineers gain valuable insights into potential failure modes prior to initiating physical tests. This approach does not save time and resources during the product development phase. Also boosts safety and reliability standards across various industries worldwide today.

– Computer-Aided Design (CAD) Tools

CAD software helps to create visualizations and model complex shapes improving designs to meet needs. It enables collaboration among teams throughout the project’s lifecycle from concept to final production ensuring all components work together seamlessly to achieve desired results at every stage.

What are the Common Applications of High Load-Bearing Aluminum Extrusions?

High-strength aluminum extrusions that can bear loads are commonly used in a variety of industries because of their balance between strength and weight as well as their adaptability and versatility for different applications.

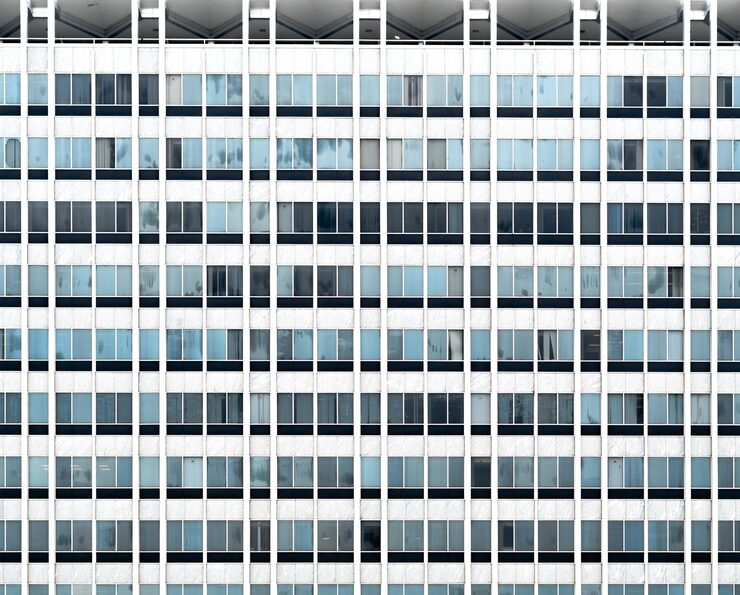

Structural Frameworks in Construction

In the construction sector architectural profiles crafted from aluminum alloys are widely used to build frameworks that support various structures such as buildings, bridges, and infrastructure projects. These materials offer enhanced durability and longevity when compared to options all while maintaining an aesthetic that meets rigorous global safety standards and regulations.

Automotive and Aerospace Components

In the aerospace industries, there are advantages to using lightweight but durable components produced with advanced extrusion technologies. This leads to fuel efficiency, lower emissions, and overall enhanced performance in both vehicles and aircraft. These advancements play a role in creating transportation solutions worldwide.

Industrial Machinery and Equipment

Industrial machinery equipment depends greatly on dependable parts that can withstand the demanding conditions and rigorous environments often found in manufacturing facilities, plants, and processing centers, around the world. Ensuring productivity and efficiency in these operations on a daily basis is essential.

What Makes Xihui Factory a Reliable Aluminum Extrusion Supplier?

When looking for a supplier of aluminum extrusions it’s important to think about things, like their experience level dedication to quality, and how well they support their customers. Xihui Factory is a standout option in this regard providing customized solutions that cater to your requirements.

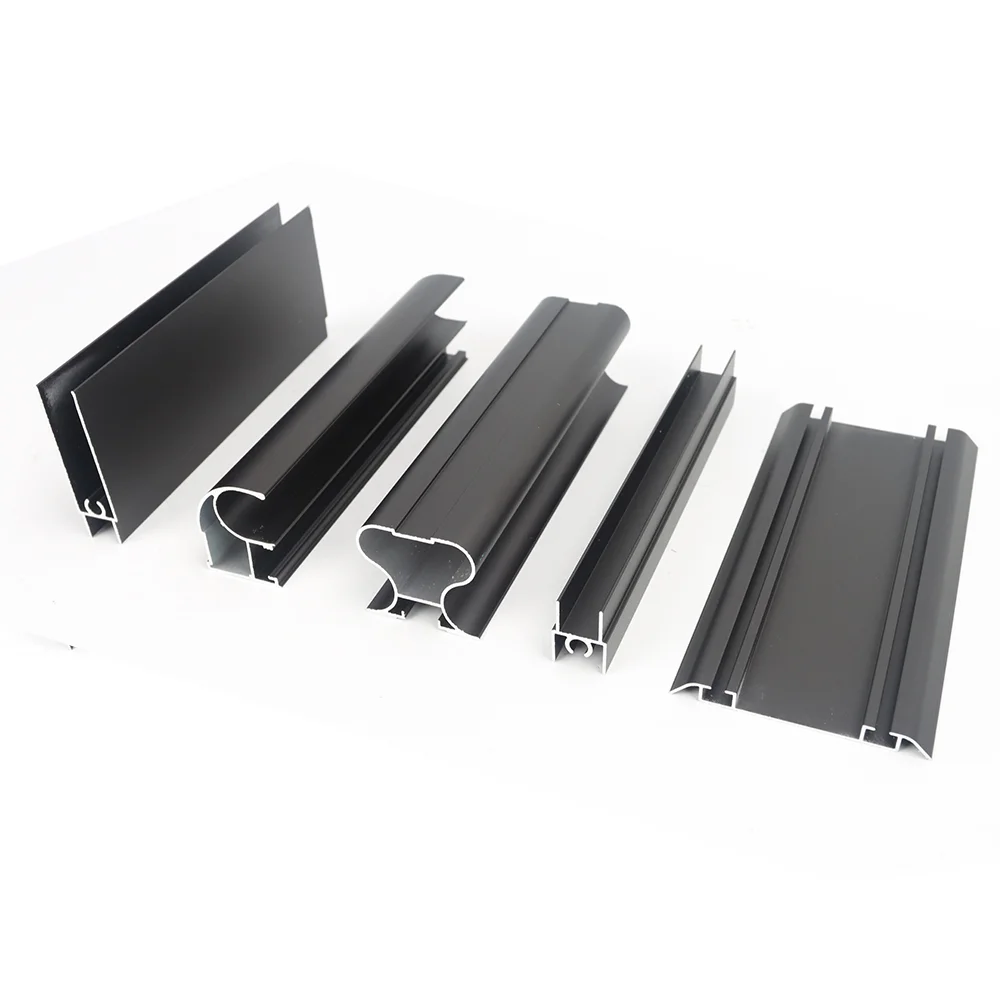

Expertise in Custom Solutions

The Xihui Factory stands out for its expertise in creating aluminum extrusion solutions using pa a production facility that features cutting-edge anodizing and powder coating equipment to guarantee top-notch quality in terms of durability and performance that goes beyond industry norms. They can meet a range of construction needs by providing services covering everything from design to shipping. By utilizing their ODM and OEM services effectively you can enjoy a procurement experience. Gain access to a wide variety of accessories and equipment options.

Commitment to Quality Standards

Xihui Factory prioritizes quality in all their operations by utilizing top-notch aluminum materials that offer environmentally friendly solutions for construction purposes. Their wide array of products includes options ranging from 0 0 3 mm to 2 2 m and comes in finishes, like polished anodized silver and a variety of powder coatings. These products are tailored to meet the needs of architects builders and contractors across sectors Whether it’s a residential or industrial project their profiles seamlessly combine practicality with aesthetics.

Comprehensive Customer Support Services

The Xihui Factory is dedicated to providing customer service to its clients by offering a range of support services tailored to meet the needs of construction contractors and suppliers in the window and door manufacturing industry and aluminum material distributors and wholesalers alike. Their holistic approach includes step-by-step assembly instructions. Guarantees that all essential components are readily available throughout your project.

FAQs About Aluminum Extrusion Load Capacity

Exploring the weight-bearing capacity of aluminum extrusions can get tricky because of factors at play Here are some common questions people ask that shed light on how much weight they can carry.

Can aluminum extrusion be used for heavy-duty applications?

Certainly! Aluminum extrusions are suitable for demanding tasks as they are crafted with the right alloy combinations and sturdy structures in mind. High-strength alloys tailored for bearing loads can greatly improve their characteristics. Adding reinforcements to the design can further bolster their capacity to withstand weights.

Are there standard tests for determining the load capacity of aluminum extrusions?

Various standardized testing methods, including stress-strain analysis, finite element analysis (FEA), and computer-assisted design (CAD) are utilized to predict potential failure modes before testing commences. This approach saves time and resources in the product development phase ultimately improving safety and reliability standards across industries today. These tests provide data on the weight-bearing capacity of extrusions under conditions enabling informed decision-making at every stage of the project lifecycle in a streamlined and effective manner.