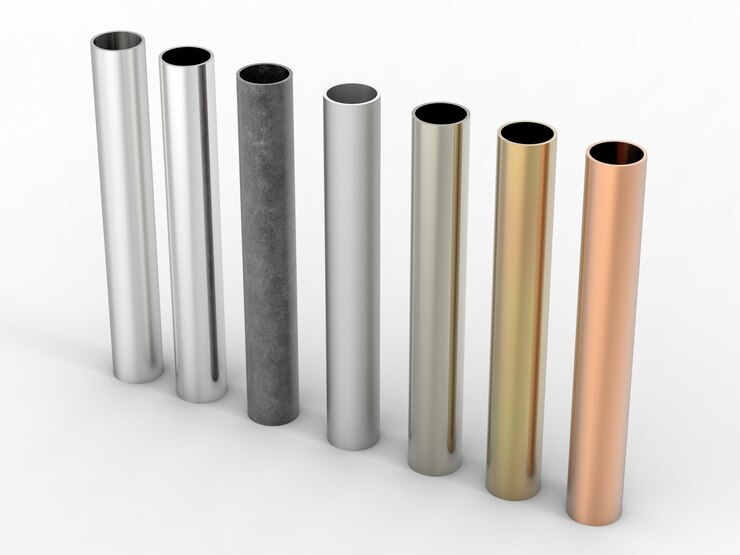

The choice between the aluminum and steel tube is very important in many industrial applications because each has its own advantages. Aluminum is lightweight, corrosion-resistant, and versatile, making it ideal for industries like aerospace and automotive. Steel, known for strength and durability, is preferred for heavy-duty applications like infrastructure and industrial machinery. This article compares their key properties, manufacturing processes, and industry uses.

Material Properties and Their Impact on Industrial Applications

Differences in Weight and Density

In the case of aluminum, the naturally formed oxide layer on the surface also enhances corrosion resistance. All these properties of aluminum make the tubes highly suitable for outdoor and marine applications involving high moisture or harsh weather conditions.

Untreated steel tends to rust and corrode over time, but the use of stainless steel can prevent this, though there are increased costs in the purchasing and maintenance of such equipment. In that way, the surface treatment, such as anodizing or powder coating, will not only prolong useful life but also make it more pleasing to the eye. Xihui Factory Aluminum’s modern manufacturing facilities are equipped with anodizing and powder coating lines, the best in their class.

Manufacturing Processes and Cost Implications

Extrusion and Fabrication Techniques

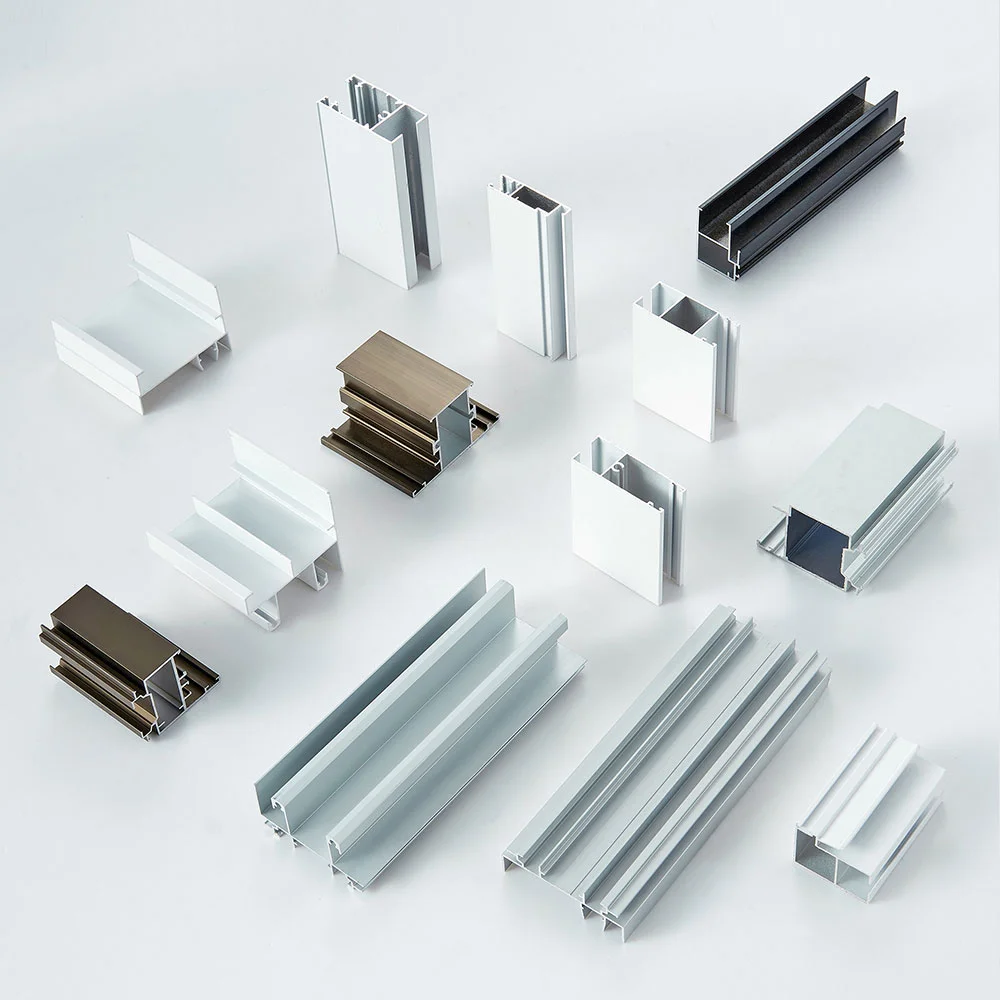

Aluminum’s ability to be easily shaped without losing its strength makes it a versatile material for creating forms using processes like extrusion in the production of industrial aluminum profiles from companies, like Xihui Factory Aluminum.

Steel fabrication typically includes intricate techniques such as welding or forging because of its sturdy nature. Although these approaches guarantee longevity they demand time and resources in contrast to the more efficient extrusion process commonly seen with aluminum.

Cost Analysis: Material and Production Costs

Raw material expenses heavily influence decision-making processes. The price per kilogram of aluminum typically exceeds that of steel. Its lightweight properties often necessitate less material for numerous uses. Furthermore, the ease of shaping aluminum minimizes labor expenses throughout manufacturing procedures.

Steel might seem cheaper at first. It needs extra money for corrosion protection methods such as galvanization or paint added to it. When you take into account these added costs along with the savings on transportation from using materials like aluminum pipes, the total expense could lean towards aluminum depending on the needs of the project.

Environmental Considerations and Sustainability

Recycling and Environmental Footprint

Aluminum is widely recognized as a recyclable material in use today maintaining its properties across numerous recycling rounds with minimal energy usage compared to initial production methods ultimately lessening the environmental impact of projects that rely on aluminum tubing.

Steel can be recycled too. It needs more energy-intensive processes compared to aluminum which is a popular choice in eco-friendly industries due to its lower carbon footprint favored in sustainability-focused projects.

Impact on Sustainable Construction Practices

Aluminum is a choice for eco-friendly construction as it helps reduce material usage while still providing strength and durability in buildings. Xihui Factory Aluminum offers a variety of products with thickness options and finishes like polished anodized or powder coatings to meet the specific needs of sustainable construction projects for architects and contractors.

Moreover, Xihui Factory Aluminium offers a range of ODM & OEM services that cover personalized design and logistical assistance to simplify the purchasing process and reduce waste in construction assembly phases – an important consideration for eco-conscious building projects.

With the use of cutting-edge technologies and a dedication to high-quality standards in place, Xihui Factory Aluminum provides industries around the globe with solutions that seamlessly match current sustainability objectives while effectively meeting unique functional needs. Discover details on this topic.

Industry-Specific Applications: Choosing the Right Material

Aerospace and Automotive Industries

The aerospace and automotive sectors require materials that offer a balance of weight and durability for their needs to be met effectively Aluminum tubes are a popular choice in these industries because of their lightweight nature which directly influences both fuel efficiency and performance The relatively low density of aluminum at around 2 7 g/cm³ allows for the creation of vehicles and aircraft that are lighter without sacrificing strength This feature is especially advantageous for parts such as fuselages wings and car frames.

Steel pipes are weightier but offer tensile strength and are commonly employed in situations demanding exceptional robustness; for instance; steel is preferred for heavy-duty truck frameworks or aerospace landing apparatuses where the ability to bear loads is vital. On the other hand aluminum inherent corrosion resistance gives it an advantage in settings exposed to diverse weather or moisture.

Construction and Infrastructure Projects

In construction and infrastructure projects the selection of materials is usually influenced by aspects like durability, affordability, and ease of setup. Aluminum pipes are frequently employed in building design for glass walls, window frames, and structural parts because of their lightweight quality and outstanding resistance to rust. These characteristics help long-term upkeep expenses while also maintaining an attractive appearance.

Steel is commonly used in projects such as bridges and skyscrapers due to its strength requirements. However, the modern techniques in aluminum production like anodizing and powder coating have made it a durable choice for outdoor uses as well. Which is great for structures that aim for sustainability and eco-friendliness.

Integrating Xihui Factory Products into Industrial Solutions

Aluminum Tube Offerings

The dedication of Xihui Factory to excellence shines through in its production plant that features cutting-edge anodizing and powder coating capabilities to guarantee that its products exceed the expected industry benchmarks for both strength and efficiency. They manufacture aluminum tubes using top-grade aluminum materials as a solution designed to meet various industrial requirements.

With thickness options ranging from 0.9mm to 2.5mm and finishes such as polished anodized silver or various powder coatings, Xihui Factory’s products cater to specific requirements across industries. Whether you’re involved in aerospace engineering or construction projects, their offerings provide the perfect blend of functionality and style.

Recommendations for Specific Industrial Needs

For industries prioritizing lightweight materials with high corrosion resistance—such as marine engineering or automotive manufacturing—aluminum tubes stand out as the optimal choice. Their ability to maintain structural integrity under harsh conditions while reducing overall weight makes them indispensable.

When selecting materials for heavy-duty applications like bridge construction or industrial machinery frameworks, steel may be preferred due to its higher tensile strength. However, integrating industrial aluminum profiles can complement these structures by providing lightweight components that enhance overall efficiency.

By leveraging Xihui Factory’s diverse product range alongside its comprehensive ODM & OEM services, industries can achieve tailored solutions that address specific functional requirements while adhering to modern sustainability goals.