Aluminum profiles play a role, in construction and manufacturing industries. They undergo a detailed fabrication process involving extrusion techniques, alongside heat treatment and surface refinement. This article delves into the stages of producing aluminum profiles the spectrum of their uses and the significance of stringent quality checks to deliver superior goods for each venture. Whether you work as an architect or builder or are involved in manufacturing processes; grasping these steps can assist you in making informed choices for your project.

What is an Aluminum Profile?

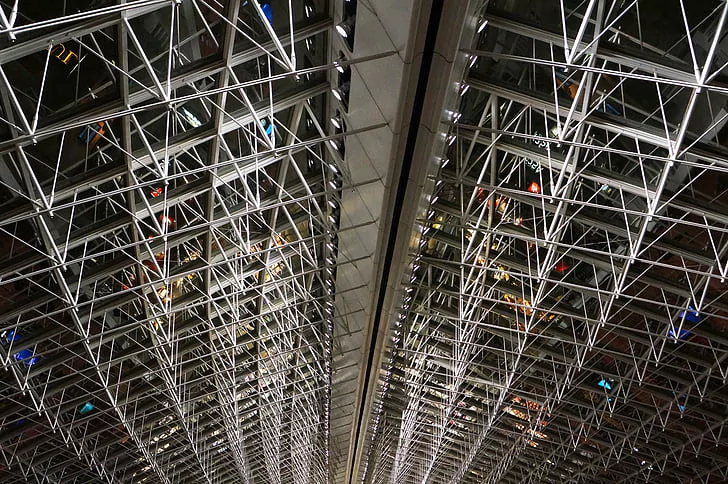

Exploring the realm of aluminum profiles reveals an adaptable element heavily employed in construction and industry settings. An aluminum profile denotes an item crafted from an aluminum alloy that delivers robustness and pliability for design purposes. These profiles find use in areas such, as windows and door installation along with curtain walls and distinct frameworks like cabinets. Their versatility renders them a favored option, among architects and constructors aiming for practical yet visually appealing answers.

What Are the Key Steps in Aluminum Profile Manufacturing?

To grasp the process of creating aluminum profiles one must delve into the steps encompassed in their manufacturing. Every phase is meticulously carried out to guarantee that the result meets the established benchmarks for quality and functionality.

Raw Material Selection and Preparation

Crafting an aluminum profile starts with choosing top-quality aluminum material to lay the groundwork for making environmentally friendly profiles. They meticulously prepare the materials to ensure they are pristine and free from impurities that might impact the product’s quality.

Extrusion Process: Shaping the Aluminum Profile

After the initial materials are ready for use in production, the extrusion process becomes crucially important in the manufacturing process of aluminum products.

Heat Treatment and Aging

Following the extrusion process aluminum profiles undergo heat treatment to improve their properties effectively. This procedure includes heating the profiles to temperatures and then carefully cooling them down. The main goal of heat treatment is to boost the strength of the material and enhance its durability, against damage over time. Additionally, aging plays a role in solidifying these characteristics by facilitating structural modifications within the material itself.

Surface Finishing Techniques

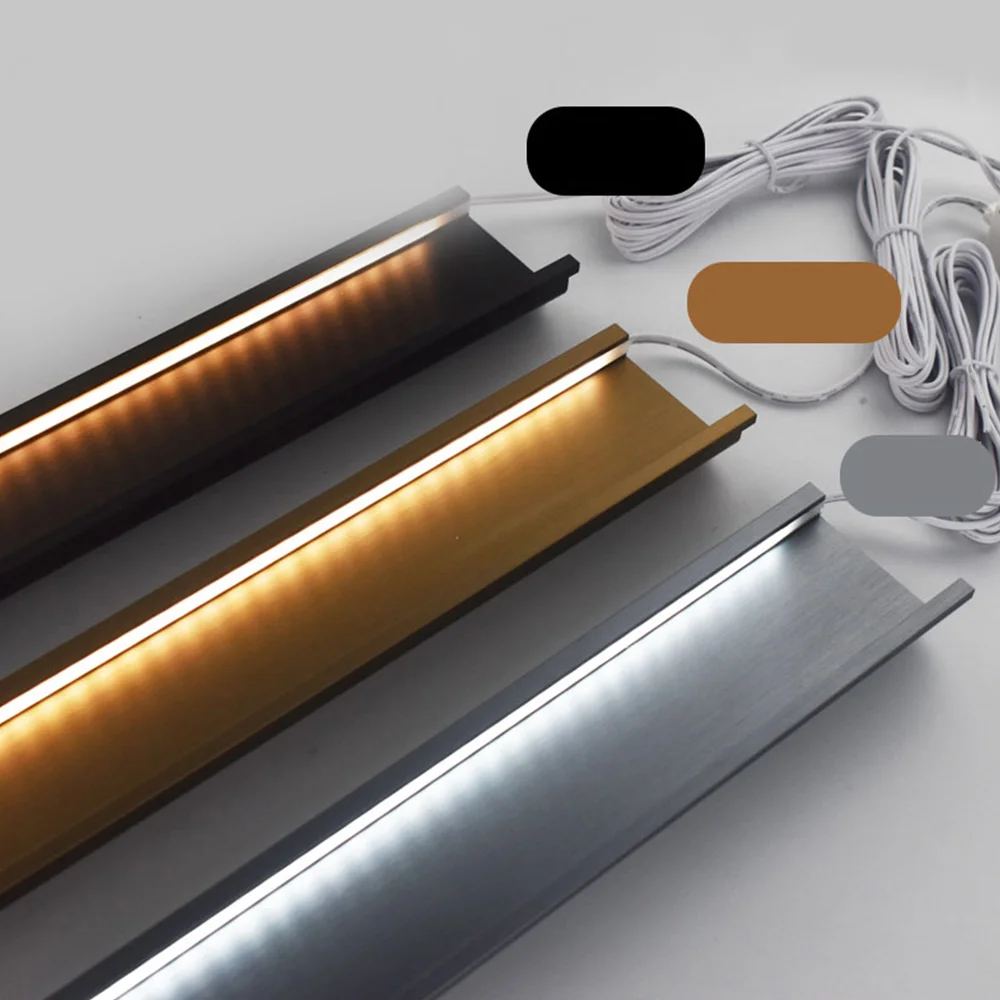

Enhancing the look and functionality of aluminum profiles relies heavily on surface finishing methods, like anodizing and powder coating processes used to create finishes like shiny silver colorful coatings for protection, against corrosion and environmental elements while enhancing longevity in various uses.

What Kinds of Profiles Can be Produced?

Aluminum profiles offer a range of options for purposes. From sliding windows and casement doors to features like curtain walls, in buildings and specialized cabinet designs that cater to unique kitchen and storage requirements while maintaining both style and practicality.

Furthermore, accommodating ODM & OEM services provides customized solutions that cover design, manufacturing, packaging, and shipping—providing advantageous flexibility, for building contractors window makers, and distributors alike. These services guarantee a purchasing process while granting entry to an array of accessories such as corner connectors, knobs, locks for door hinges, bolts, sliding wheels, and sand-based silicone sealants series as well as various others.

When you delve into every stage of creating aluminum profiles starting from choosing the materials to finishing the surface you get a glimpse of how these crucial elements are carefully made to cater to various industry requirements while upholding strict quality benchmarks.

How Is Quality Control Maintained in Aluminum Profile Production?

Quality assurance of aluminum profiles is a factor in the manufacturing process that must not be underestimated. As a professional in this field, you comprehend the significance of upholding quality control standards to meet both industry benchmarks and customer demands. This entails examination and testing protocols to detect flaws and uphold uniformity across the product range.

Inspection and Testing Procedures

In the world of manufacturing aluminum profiles, inspection and testing processes are implemented throughout stages to ensure that every product meets the necessary standards. These processes involve;

- Dimensional Checks: Ensuring that profiles adhere to precise measurements as per design requirements.

- Surface Quality Assessment: Evaluating finishes for uniformity, color consistency, and absence of blemishes.

- Mechanical Testing: Conducting tests to assess strength, durability, and resistance to environmental factors.

- Chemical Composition Analysis: Verifying that the aluminum alloy used meets specific standards for purity and composition.

It’s important to follow these steps to pinpoint any variances from the quality standards and take corrective measures quickly.

Addressing Defects and Ensuring Consistency

Fixes in aluminum profiles are crucial for ensuring product quality remains intact. Furthermore maintaining consistency is possible through procedures and ongoing supervision. Manufacturers ensure levels of accuracy during production by utilizing technology and skilled workers which ultimately improves dependability for consumers.

Why Is Xihui Factory a Reliable Aluminum Profile Supplier?

When you’re looking for an aluminum profile supplier as someone experienced in the industry like yourself. Having trust in their reliability is crucial Xihui Factory has built a reputation as a trusted partner by focusing on delivering top-notch quality products and services while also being innovative and customer-oriented.

Commitment to Quality and Innovation

The dedication of Xihui Factory to excellence is clear in its manufacturing facility which features anodizing and powder coating equipment. Their setup guarantees that every item not only t meets but exceeds the established standards in terms of durability visual appeal and functionality. Incorporating high-quality aluminum material further emphasizes their commitment to providing solutions for construction requirements.

Customer-Centric Approach

It is crucial for Xihui Factory to prioritize understanding your needs as a customer above all else. Therefore, it offers a range of ODM & OEM services that are customized to meet your requirements. This includes services ranging from design and production to packaging and logistics delivering a procurement process. This adaptability is advantageous for construction contractors windows manufacturers, distributors, and wholesalers alike as they receive guidance on assembly and have access to a selection of accessories.

At Xihui Factory we prioritize our customers by providing solutions to meet your needs all while guaranteeing effective service in every interaction we have with you.

FAQs on Aluminum Profile Production

What types of materials are utilized in the manufacturing of aluminum profiles?

High-grade aluminum alloys are selected for their strength, durability, and eco-friendliness in producing robust profiles suitable for various applications.

What impact does the extrusion process have on the formation of aluminum profiles?

The extrusion process involves heating aluminum billets before forcing them through a die to achieve specific shapes as per design requirements—allowing precise control over dimensions.

What surface finishing techniques are applied?

Advanced anodizing and powder coating lines apply finishes such as polished anodized silver or various colored coatings—enhancing both appearance and protection against corrosion.