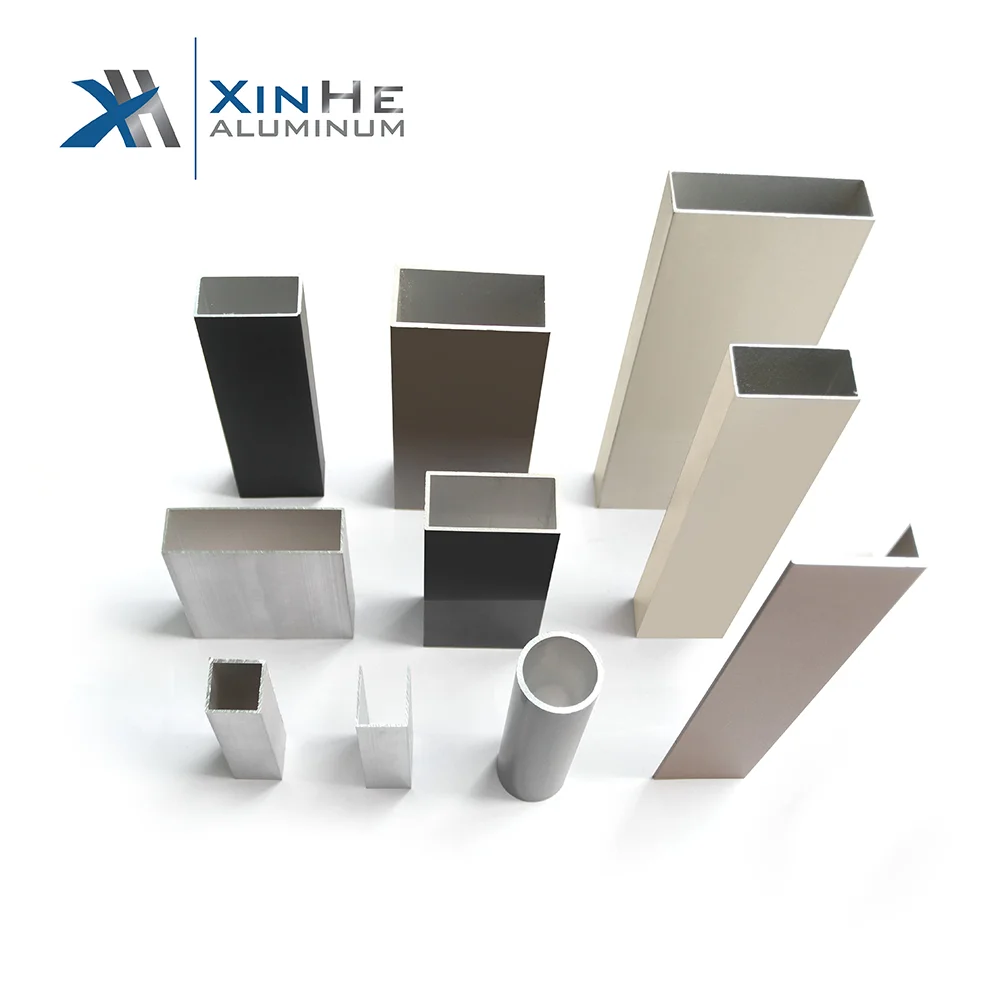

The world of manufacturing has seen numerous innovations over the years, but none stand out quite like the advancements in CNC machining. A leading example of this is the use of CNC-machined aluminum components that are reshaping industries with their blend of durability and elegance. The aluminum extrusion cnc process allows for precision crafting of these components, making them an ideal choice for various applications.

Aluminum extrusion cnc is a process that uses advanced technology to design and produce aluminum casings that are not only visually appealing but also highly functional. The meticulous craftsmanship of these casings can be attributed to the advanced CNC (Computer Numerical Control) machining technology. This ensures that each piece is crafted with unparalleled precision, featuring smooth surfaces and impeccably shaped cutouts for practicality, such as port openings and indicator slots. The anodized coloring used in these components not only preserves the material’s integrity but also delivers a stunning, scratch-resistant finish.

These aluminum components are designed to blend lightweight portability with superior robustness, making them suitable for electronic housing or premium-grade enclosures in various industries. The geometric cutouts of these aluminum casings offer adaptability, making them functional for a multitude of end-use applications, ranging from high-end electronics to luxury device exteriors. Whether you are working in consumer electronics or seeking a statement piece for a manufacturing project, these aluminum bodies promise structural dependability and aesthetic finesse that sets your products apart.

Furthermore, aluminum extrusion cnc technology has paved the way for the creation of sleek and contemporary accessories such as power banks and vape devices. Each unit is crafted from high-quality aluminum, ensuring both durability and an elegant finish. Available in a range of vibrant anodized colors, these power banks and vape devices are engineered for optimal performance. The power banks are designed to offer high-capacity charging, keeping your devices powered throughout the day, with a minimalist design that features smooth edges and a slim profile.

Incorporating these state-of-the-art aluminum enclosures into projects provides a perfect harmony of style and functionality. Engineers seeking reliable housing for electronic boards, designers aiming for a modern aesthetic, or tech enthusiasts desiring custom looks for their devices will find these casings to be indispensable. The fusion of meticulous craftsmanship and modern technology ensures that these aluminum enclosures deliver top-notch performance and sophistication for every application.

In conclusion, the versatility and elegance offered by CNC-machined aluminum products, such as enclosures and accessories, are unparalleled in the industry. Their precision engineering and striking appearance make them a true asset for manufacturers and consumers alike, promising a seamless blend of strength, style, and adaptability, redefining the boundaries of modern design and functionality.