Are you looking for customized solutions for your aluminum profiles? Opt for tailored CNC machining services for aluminum profiles to receive designs that match your exact needs, which can enhance performance and efficiency across industries. Take a look at this blog to learn how CNC machining can address the demands of your project.

What is Custom Aluminum Profile CNC Machining?

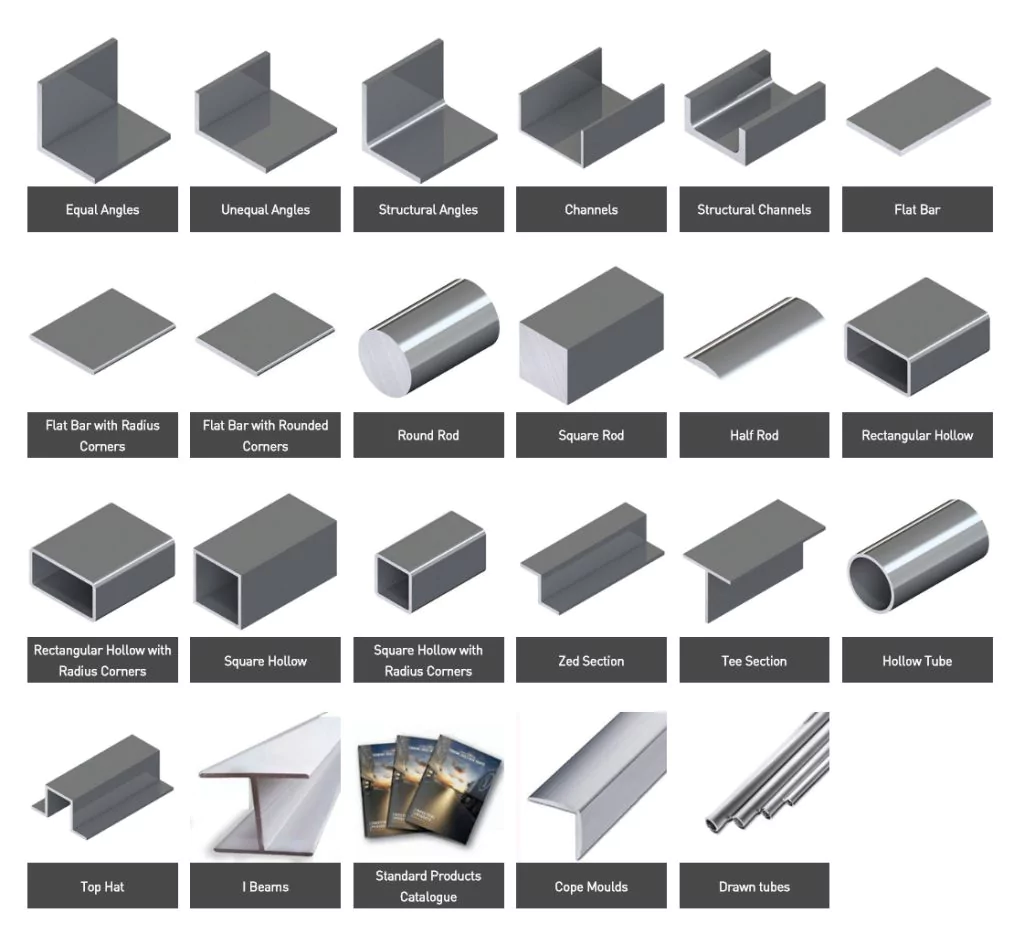

Crafting custom aluminum profiles with CNC machining involves using computer numerical control, or CNC to accurately shape and cut aluminum according to needs and designs to create unique solutions.

Overview of CNC machining

In the world of CNC machining – a manufacturing method where controls are utilized to operate machine tools – software is vital for directing machinery to cut and mold components with precision and accuracy while enhancing efficiency and reducing the chances of errors resulting from human involvement.

Importance of adaptation in CNC machining

We must adjust CNC machining to meet project requirements efficiently and effectively by tailoring machining processes to fit needs and design specifications accurately for intended use purposes such as shapes and material properties in perfect alignment with the project demands.

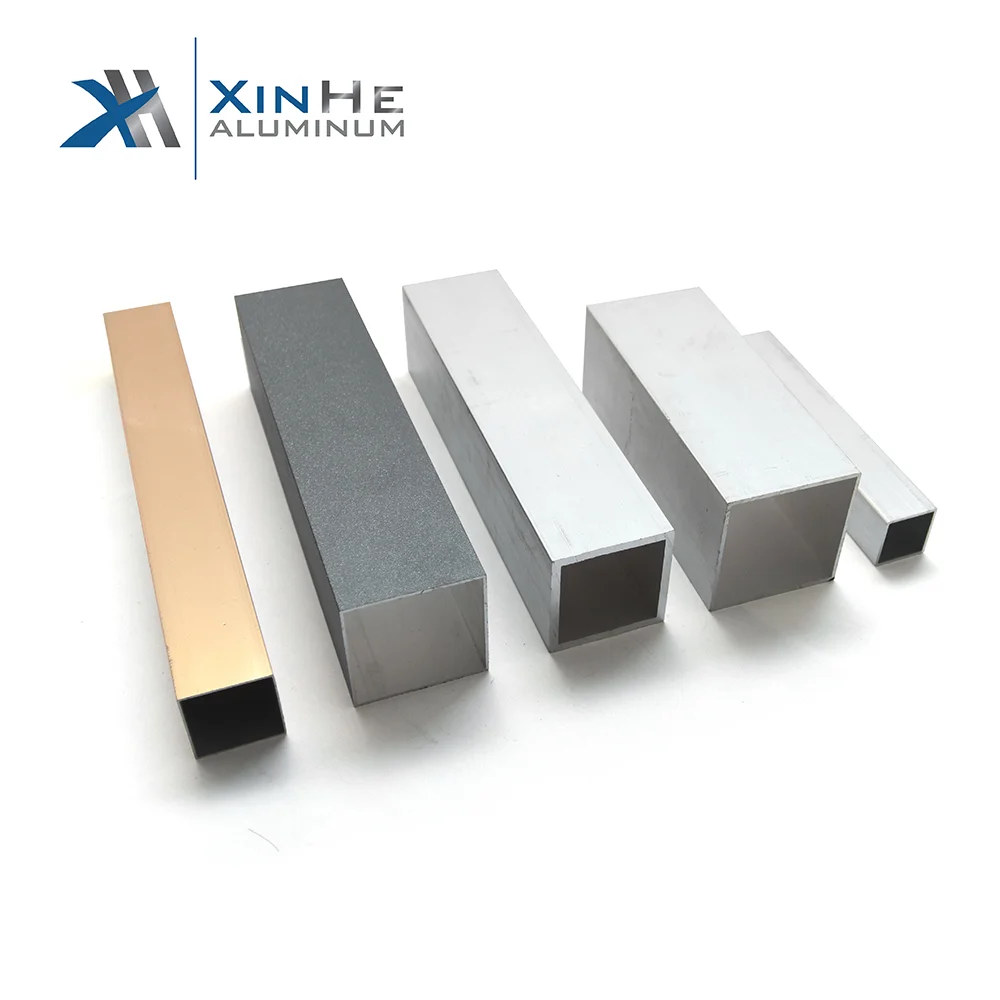

Advantages of Using Aluminum Profiles

When you employ aluminum profiles in CNC machining processes, you can benefit from their durable nature, which makes them ideal for various applications. Additionally, these profiles show corrosion resistance and possess excellent thermal conductivity enhancing their versatility and popularity across different industries.

How Does CNC Machining Ensure Precision?

Precision plays a role in the realm of CNC machining to ensure that each component meets the necessary standards and upholds quality benchmarks.

Techniques for Achieving High Precision

Numerous techniques are employed to guarantee precision in CNC machining.

- Tight Tolerances: Maintaining strict tolerances ensures components fit together seamlessly.

- Advanced Tooling: Utilizing cutting-edge tools enhances accuracy.

- Precision Programming: Detailed programming of machine operations reduces errors.

Role of Technology in Enhancing Accuracy

In CNC machining processes today technology helps improve accuracy by using software tools to manage every detail precisely. Real-time monitoring systems also play a role detect deviations quickly and prompt timely corrective actions.

Quality Control Measures in CNC Machining

Ensuring top-notch quality control is vital for maintaining excellence in CNC machining.

- Regular Calibration: Ensures machinery operates within required parameters.

- Inspection Protocols: Comprehensive inspections verify component quality.

- Feedback Loops: Continuous feedback helps refine processes for better outcomes.

Why Choose Custom Solutions for Aluminum Profiles?

Opting for tailor-made solutions for aluminum profiles provides advantages tailored to suit your needs.

Benefits of Tailored Aluminum Profiles

Custom aluminum profiles offer unique benefits:

- Design Flexibility: Adapt designs to suit particular applications.

- Material Efficiency: Optimize material usage based on project demands.

- Enhanced Performance: Achieve desired functionality through specialized designs.

Industries That Benefit from Customization

Various industries benefit from designed aluminum profiles.

- Automotive: For lightweight yet durable components.

- Aerospace: Precision parts critical for safety and performance.

- Construction: Tailored profiles for architectural elements.

Cost-Effectiveness of Custom Solutions

Crafting solutions have the potential to lower costs through waste reduction and productivity enhancement. Tailoring products to fit your needs maximizes resource utilization and minimizes unnecessary expenses by decreasing reliance on materials or adjustments after production is complete.

What Are the Applications of Custom Aluminum Profile CNC Machining?

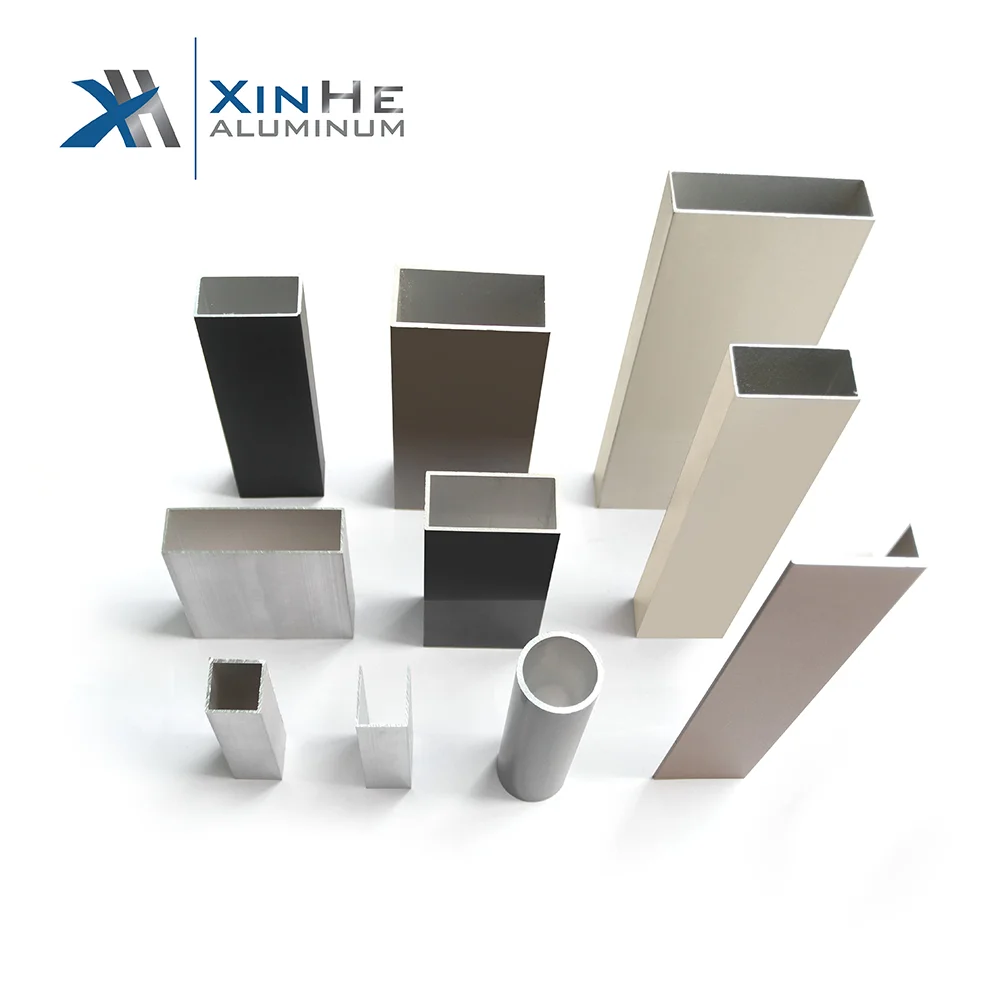

Custom aluminum profile CNC machining is widely used in industries because of its accuracy and adaptability advantages. Understanding these practical applications can provide insights into the versatility and importance of this technology.

Automotive Industry Applications

Custom aluminum profile CNC machining contributes to enhancing the performance and efficiency of vehicles in the sector by enabling the production of parts with exact specifications, crucial for modern automotive designs.

Use in Vehicle Components

Car parts, such as engine components and suspension parts are produced with CNC machining technology to ensure accuracy and adhere to quality requirements that are essential for the safety and efficiency of vehicles.

Lightweight Structures and Efficiency

Aluminum lightweight is ideal for building vehicle frames and parts that need to be both strong and lightweight at the time. By utilizing aluminum profiles instead of other materials, you can make things lighter without sacrificing durability it, not only helps with fuel efficiency but also meets the eco-friendly standards set by the industry nowadays.

Electronics and Consumer Goods

In the electronics and consumer goods industries today, custom aluminum profile CNC machining plays a role in creating intricate designs with the precision needed for modern electronic products.

Housing and Enclosures

Aluminum profiles are commonly used in making enclosures and cases for devices that require measurements to ensure the proper fit of internal parts. CNC machining allows for the creation of designs that can accommodate circuitry while maintaining structural strength.

Heat Dissipation Components

Aluminum’s excellent heat conductivity makes it a popular choice for tasks that require heat dissipation optimization purposes, like cooling solutions and heat sinks crafted, using CNC machining techniques in devices to regulate temperature effectively and enhance overall performance.

Construction and Architecture

In construction and architecture circles, custom aluminum profiles are recognized for their looks and structural benefits. Designers and builders utilize CNC machining to craft structures that meet requirements while also making a visual impact.

Structural Frameworks

Aluminum profiles are essential in building structures due to their strength-to-weight ratio and can be tailored using CNC machining to meet precise architectural needs effectively while maintaining stability with minimal material use.

Decorative Elements

Aluminum profiles serve more than structural functions—they are also utilized for decorative elements such as facades and railings, and in crafting window frames to enhance the aesthetic appeal of buildings through the precise craftsmanship of intricate details using CNC machining techniques.

XiHui Aluminium Co., Ltd.: a Trusted CNC Supplier

When looking for a company to meet your custom aluminum profile CNC machining needs, XiHui Aluminium Co. Ltd stands out as a trusted option among service providers known for their reliability. XiHui uses technology and machinery to achieve results in their work procedures. They are known for their expertise in CNC machining and dedication to satisfying customer requirements, which makes them the ideal choice for projects that require precision and adherence to strict tolerances. Working with a company like Xi Hui Aluminum ensures the success of your machining endeavors.

FAQs

Delving into the details of CNC machining for aluminum profiles can assist you in making choices for your projects. Here are some common inquiries that tackle typical concerns.

1. What are the lead times for custom aluminum profile machining?

Lead times for custom machining of aluminum profiles can vary due to a range of factors. During the planning stage you can request cost estimates and ensure that your parts will arrive on time as promised.

2. Can custom aluminum profiles be anodized or finished post-machining?

Absolutely! Make sure to communicate your desired finish details to your CNC supplier so they can recommend finishes that align with the intended purpose and environment of the product for optimal aesthetics and functionality.

3. Is it possible to modify an existing aluminum profile design with CNC machining?

You have the choice to modify aluminum profile designs through CNC machining services for tweaking dimensions or incorporating features to improve performance without compromising on quality.