Looking for precision and reliability in custom aluminum CNC machining? Learn how strict quality control at every step ensures top-tier products and hassle-free service. This blog will give you a detailed introduction.

What is the Quality Control Process in Custom Aluminum CNC Machining?

Custom aluminum through CNC machining requires a quality check to guarantee that each item meets the strict standards set for optimal performance and durability during the production process.

Importance of quality control in CNC machining

Quality assurance in CNC machining is more than one step-it is a requirement that guarantees every part, performing innocently to meet the precise measurement and tolerance required for the final product. By applying the quality control protocol, errors can be avoided and eventually promote the dependence of aluminum components used in a range of applications..

Key Steps in the Quality Control Process

The custom aluminum CNC machining quality assurance procedure involves a series of stages that ensure precision and accuracy at each step of the process.

Inspection and Testing

Quality control entails processes like inspection and testing to ensure the integrity of aluminum components meets the designated design standards accurately. Through thorough scrutiny and assessment of each part for consistency, make sure specific requirements from the beginning to promptly rectify any deviations found during the evaluation process.

Precision and Accuracy Checks

Ensuring that every machined part meets standards requires thorough precision and accuracy checks. These evaluations entail utilizing measuring instruments to evaluate measurements and tolerances, guaranteeing that your items are meticulously crafted with the highest level of accuracy.

Final Product Evaluation

The assessment of the end product is the culmination of the quality audit process, whereby each component is stringently checked to verify its suitability for deployment.

How does CNC Machining Attain Accuracy in Aluminum Components?

Various techniques are used in CNC machining to guarantee the accuracy of aluminum components while meeting your requirements and standards effectively.

Advanced Machinery and Technology

Utilizing machinery and technology plays a crucial role in ensuring accuracy in CNC machining processes. With cutting-edge equipment enabling the creation of designs and intricate geometries, you can expect top-notch components that adhere to precise requirements.

Role of Skilled Technicians

Experienced professionals are essential to the CNC machining process, because they guarantee the operation of machines and make necessary adjustments while quickly resolving any issues that arise. It is a vital aspect in upholding top-notch quality standards.

Continuous Monitoring and Adjustments

Making adjustments as needed while machining is crucial for maintaining precision and consistency in the production process. Regularly evaluating operations allows technicians to fine-tune performance and make necessary changes to make each manufactured part meets the specified requirements.

Why Choose Custom Aluminum CNC Machining for Your Projects?

When starting a project that demands accuracy and strength, choosing customized aluminum CNC machining can make a difference in the outcome of your work. This method guarantees that your parts are designed to fit your needs and takes advantage of the natural strengths of aluminum as a material. Knowing the reasons behind the effectiveness of this technique can assist you in making informed choices for your undertakings.

Benefits of Customization

Personalizing your CNC machining process gives you the freedom to fully dictate the design and details of your components, which proves invaluable when working with shapes or specialized uses.

- Tailored solutions that meet exact project requirements.

- Enhanced functionality by integrating specific features into the design.

- Improved performance through precise engineering adjustments.

Versatility of Aluminum as a Material

Aluminum flexibility makes it a great option for CNC machining endeavors because of its features that provide various benefits, such as:

- Light but strong, hence suitable for multiple applications.

- Corrosion-resistant, which prolongs the life of parts.

- Distinguished electrical and thermal conductivity, widening its area of use across industries.

Cost-Effectiveness and Efficiency

In any manufacturing process, efficiency and cost-effectiveness should be prioritized at all costs. Both are achievable through custom aluminum CNC machining.

- Reducing material waste through precise cutting and shaping.

- Minimizing production time with automated processes.

- Lowering costs associated with post-production finishing due to aluminum’s favorable properties.

Who are the beneficiaries of Custom Aluminum CNC Machining Services?

Various applications and industries are improved by personalized aluminum CNC machining services, improving product quality and performance that they offer to various consumers.

Industries that rely on CNC machined parts

Most industries rely significantly on CNC machined parts because of their requirement for precision and reliability, such as:

- Aerospace: For components that require high strength-to-weight ratios.

- Automotive: For parts that demand durability under varying conditions.

- Electronics: For intricate components that necessitate exact specifications.

Applications of Aluminum Parts in Various Sectors

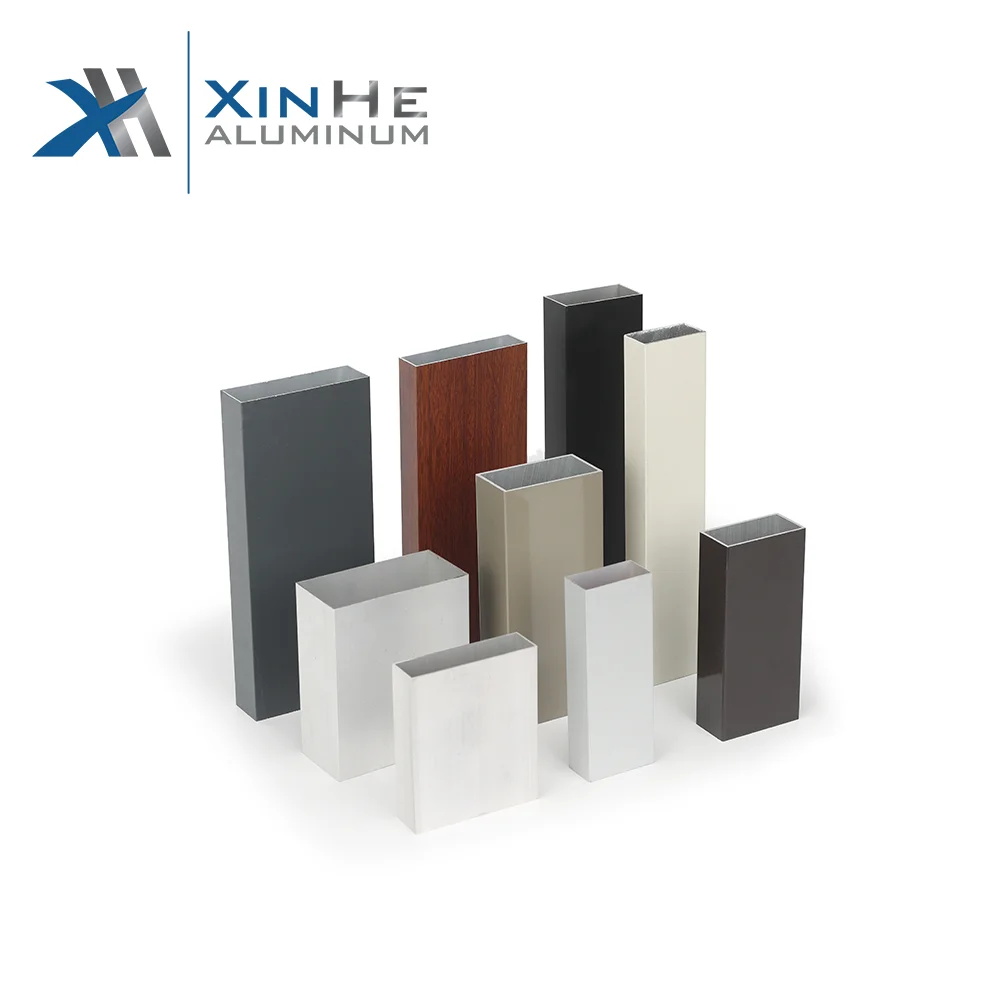

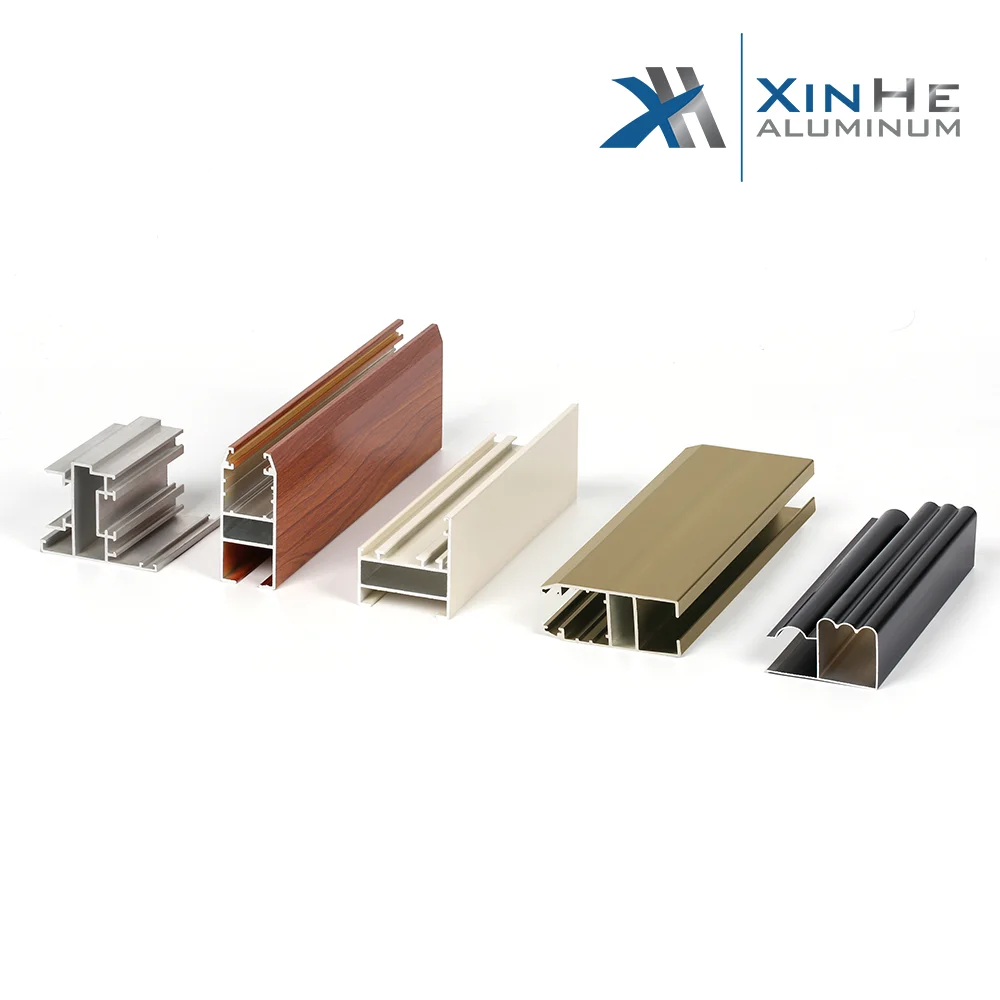

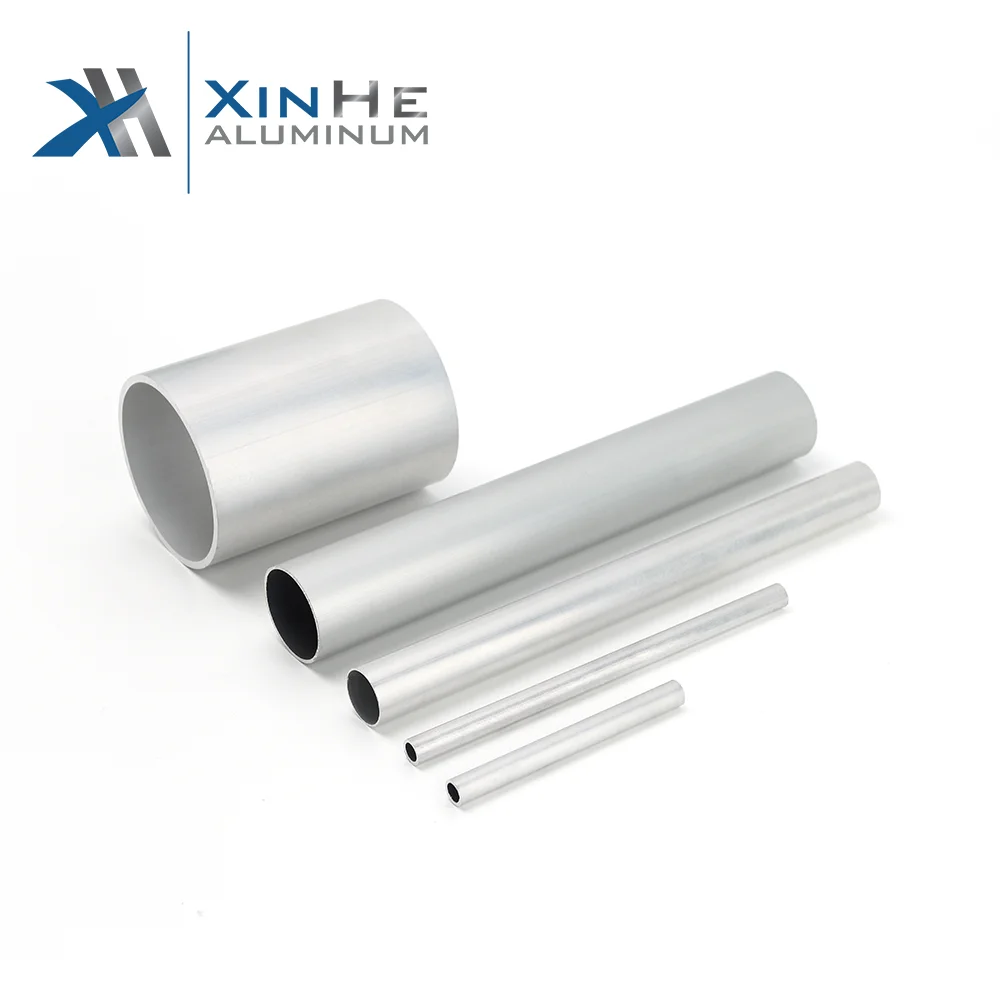

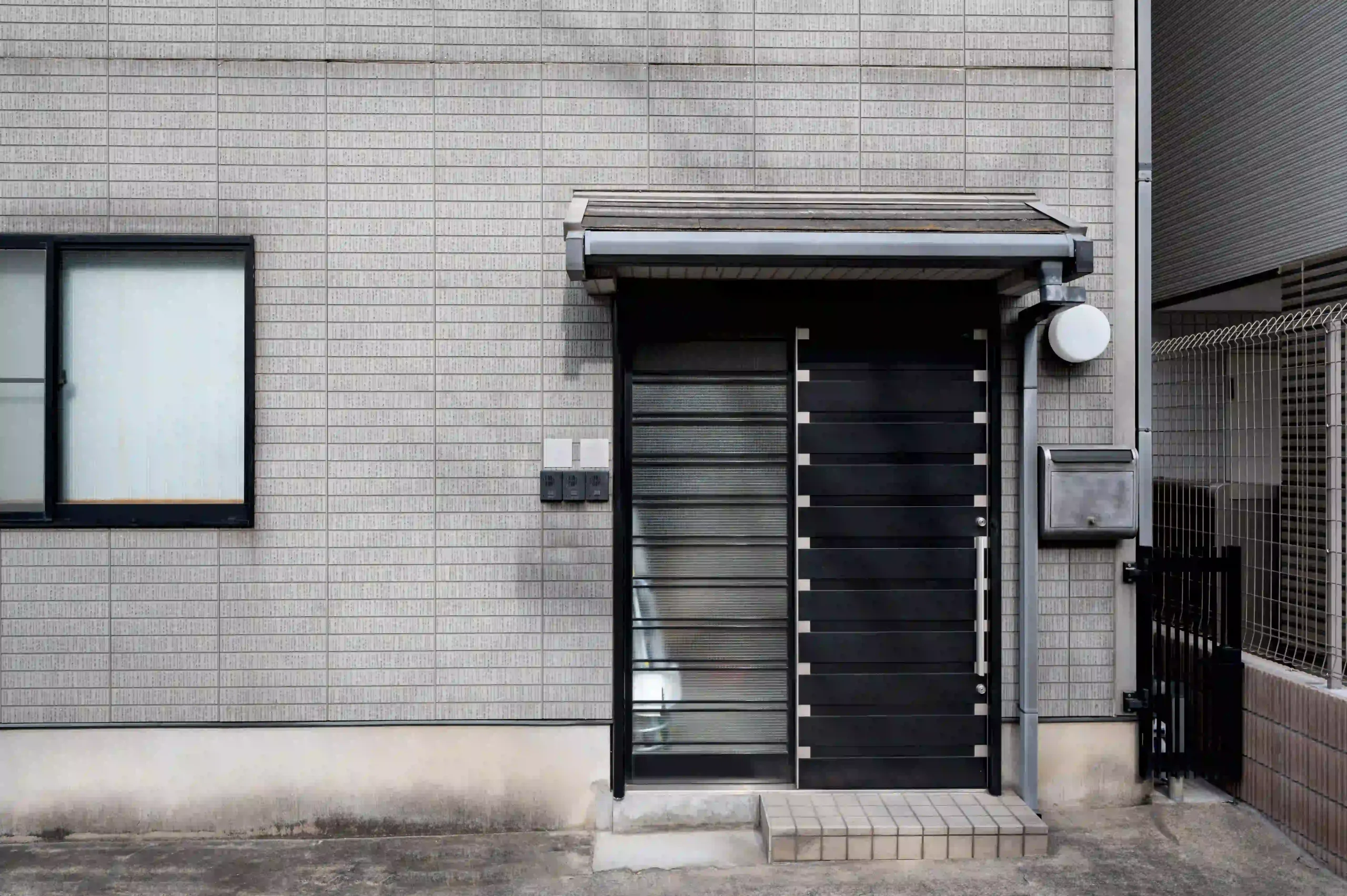

Aluminum components are utilized in industries for their practical and visual advantages. Primarily employed for aluminum alloy sliding windows and doors as well as for casement doors and windows made of aluminum alloy. Additionally utilized in the construction of modern-looking structures such as the sleek and transparent installations known as “glass curtain walls.”

When you opt for personalized aluminum CNC machining services, you’ll have the advantage of a manufacturing method that caters to various requirements while upholding quality standards consistently during the production process.

Why XiHui Aluminium Co., Ltd is Your Go-To Supplier for Aluminum Alloy?

XiHui Aluminum Co., Ltd. is a trusted aluminum alloy solution partner that has a complete range of profiles like sliding, casement, and shopfront door series for particular architectural and commercial applications. They have a very state-of-the-art manufacturing plant with excellent anodizing and powder coating lines to create high-quality long-lasting, visually pleasing, and performing products. The company ensures strict quality control by utilizing A-grade aluminum for offering green, long-lasting products. With full-scale ODM and OEM capabilities, they offer tailored solutions in design, production, packaging, and logistics to cater to various customer requirements effectively.

FAQs

When thinking about custom aluminum CNC machining for your projects, you might have questions about lead times, machining operations, and any production limitations that may arise. Having these asked questions answered can help make things clearer on any questions you may have.

Q: Are size or shape limitations placed on what can be CNC machined?

A: CNC machining is highly versatile in creating shapes and sizes, but there are some limitations depending on the properties of the machinery and materials being used in the process.

Q: Can CNC machining support complex aluminum alloy designs?

A: Yes, CNC machining is ideal for detailed designs. It can provide close tolerances, detailed finishing, and precision cuts, so that aluminum alloy parts fit into strict dimensional requirements without compromising on strength or aesthetic appeal.

Q: What surface finishes are available for CNC-machined aluminum alloy parts?

A: Standard surface finishes include anodizing, powder coating, sandblasting, and polishing. These processes introduce corrosion resistance, aesthetic enhancement, and durability.