When it comes to precision, durability, and versatility, aluminum CNC machining stands out as a top choice for many industries. In this blog, we’ll explore why choosing aluminum for your projects can provide exceptional results, from cost savings to enhanced product quality. Let’s dive into the key benefits of aluminum CNC machining and how it can elevate your manufacturing process.

Why Aluminum CNC Machining for Your Projects?

When initiating a new project, the right material and process must be selected. Aluminum CNC machining is one of them that is suitable and highly recommended, with numerous benefits that can suit most companies.

Advantages of Using Aluminum in CNC Machining

There are certain traits which make aluminum an excellent metal to work with in the world of CNC machines. The better you know how to work with aluminum, the more you will find yourself convinced to do it yourself.

Lightweight and Durable Properties

Largest of all distinguishing features of aluminum is that aluminum is light in weight but incredibly strong. This makes it exceptionally useful in application scenarios where lightness is vital without compromising strength. With the use of aluminum, you can experience a product that can perform under harsh conditions of the environment and still have its integrity as a structure intact. Our clients have always benefited from our custom aluminum CNC machining service because it delivers parts that have stringent strength and weight constraints.

Cost-Effectiveness and Efficiency

Aluminum is not only easily available but also low in cost, so it’s an easy choice for low-budget projects. Machine ability gives fast production time with reduced labor cost and increased efficiency. You can achieve high accuracy and intricate designs with less wastage, thereby saving money as well.

Versatility of Use

The diversity of aluminum CNC machining spans industries as an attractive alternative. In aerospace, automotive, electronics, or consumer goods, there’s only that much you can do with aluminum.

Aerospace and Automotive Industries

Within the automotive and aviation industries, in which safety and performance are key, aluminum’s strength-to-weight ratio is particularly attractive. It enhances fuel efficiency and minimizes emissions by providing a weight saving for an entire vehicle.

Electronics and Home Appliances

The corrosion resistance and thermal conductivity of aluminum make it the ideal choice for consumer electronics and products. Its heat-dissipation feature causes electronic devices to operate for a longer duration of time while providing an appealing appearance.

How Does Aluminum CNC Machining Improve Product Quality?

In terms of product quality, material and production are important. Aluminum CNC machining is a technique that greatly improves the quality of the product, with precision and longevity in every single part made.

Precision and Accuracy in Production

Precision and accuracy are the key components of having quality products. CNC machining with aluminum is the best here since it offers unbeatable precision to manufacture complex parts. You can rely on the technology to develop components with sophisticated geometries and narrow tolerances, such that each component is accurate to specs.

Tolerances Achievable by CNC Technology

One of the aspects of CNC technology is that narrow tolerances are achievable. Through aluminum CNC machining, you have precision required for procedures where precise measurement and flawless performance are crucial.

Surface Finishing Techniques for Aluminum Parts

In addition to precision, completion of aluminum components also plays a role in their form and function as well as overall appearance. Aluminum CNC turning provides several surface finishes techniques that provide looks and longevity.

Anodizing, Polishing, and More

Surface treatment processes such as anodizing and polishing greatly improve aluminum components. Anodizing increases corrosion protection and the option of coloration, resulting in a stunning appearance that is resistant to weather. Polishing achieves improved surface smoothness, glossy appearance, and preservation of strength in the part.

How Do Companies Gain Advantage from Custom Aluminum CNC Machining?

As today’s competitive business environment keeps shifting, businesses always look for a way to maximize efficiency in operations and deliver superior products. CNC machining of aluminum offers competitiveness with solutions that meet the requirements to enhance product development cycles. The technology helps companies attain increased efficiency, accuracy, and innovativeness in production processes.

Customized Solutions to Meet Individual Requirements

One-time specialty CNC aluminum machining is also distinct in its ability to create customized products according to specific business requirements. The process insures each item is not just designed and made but does so with accuracy which enables conformity with high standards levels, thus producing levels of customizations not accessible with other processes.

Options Available for Customization

The versatility of bespoke aluminum CNC machining is because of the great extent of its customizable features. You can select varied design topologies, material specifications, and finishes to create components that are shaped exactly in line with your project needs. Whether intricate shapes or custom characteristics, this process is capable of offering high levels of customization.

Improving Product Development Cycles

With the velocity of the new market, decreasing time-to-market is crucial for staying competitive. Custom aluminum CNC machining is core to the velocity of product development cycles through increased prototyping and iteration cycles.

Accelerated Iteration and Prototyping

The accuracy of aluminum CNC machining significantly accelerates the prototyping cycle, allowing you to test and iterate designs quickly before large-scale production. The ability to rapidly iterate cuts lead times and increases responsiveness to customer demand.

How Do Success Stories Point to Aluminum CNC Machining Strength?

In manufacturing, success stories provide powerful attestation to the efficacy and reliability of a particular process. Aluminum CNC machining has persistently proven its strength in numerous practical applications across various industries. Through these instances, you realize how you can leverage the technology to achieve excellent results.

Real-Life Applications in Numerous Industries

Versatility is reflected in CNC machining of aluminum through how it gets applied across numerous industries. It is versatile enough to be an enterprise’s default choice for improving products and processes.

Notable Projects Realized Through Aluminum CNC Machining

There have been several high-visibility projects wherein aluminum CNC machining has played a critical role in delivering successful outcomes. Whether they are aerospace components that need light yet durable material or automotive components that demand precision engineering, aluminum CNC machining has proved to be of immense value.

Customer Rating for Performance and Dependability

The ultimate verification of any production process is customer satisfaction. Feedback from customers after use of aluminum CNC machining always appears to stress the performance and reliability of machined parts. This feedback is the testament of faith in expertise and to the reliability of quality.

Why XiHui Aluminium Co., Ltd is a Reliable Supplier?

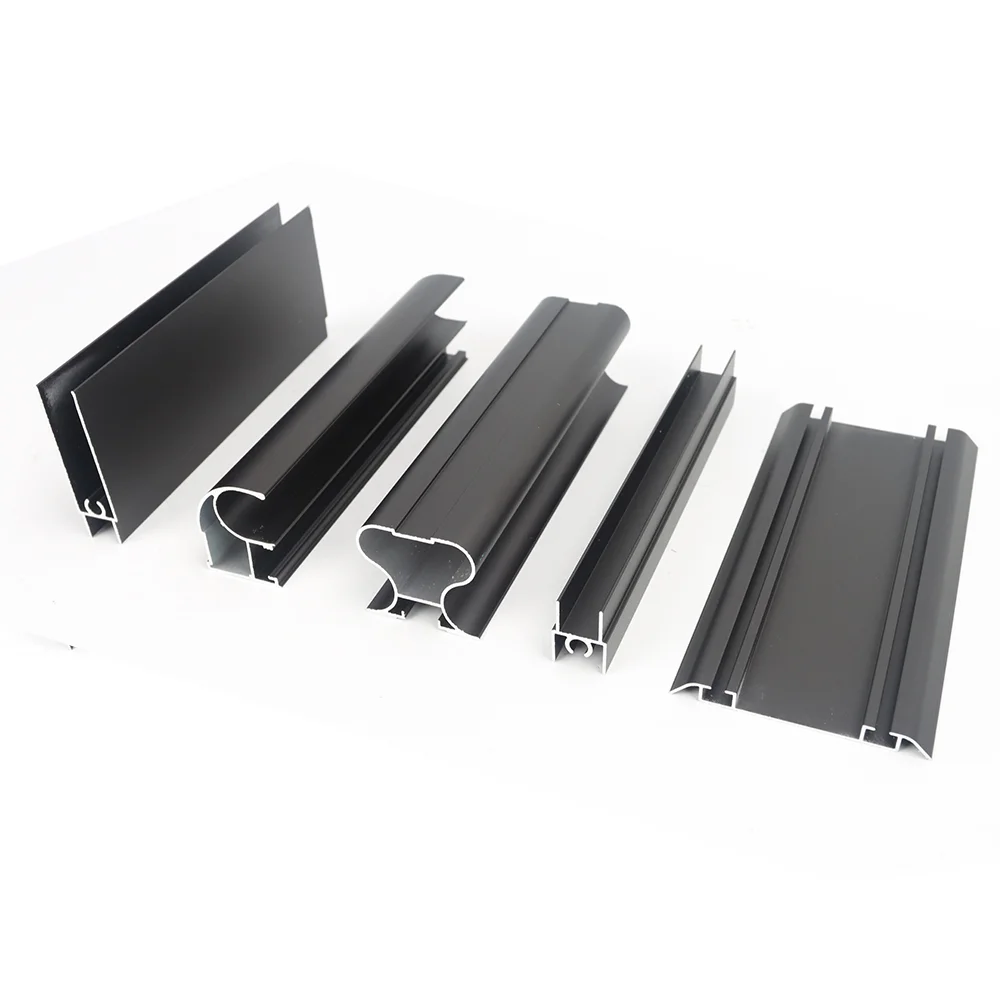

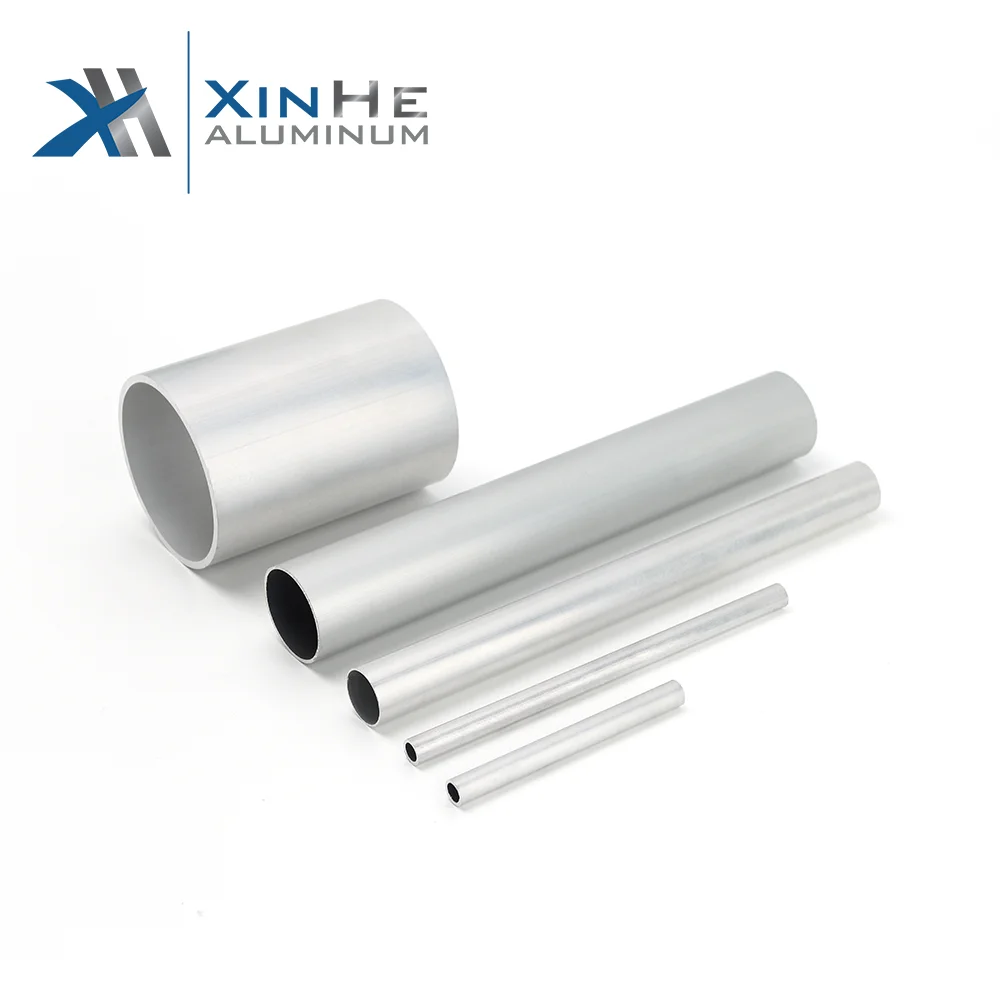

Foshan Xihui Aluminum Co., Ltd. is a 30-year-old company that specializes in the manufacture of aluminum extruded profiles. Xihui possesses 15 extrusion production lines, 2 anodizing lines, 2 powder coating lines, and 40 CNC deep processing lines. The company is capable of producing aluminum profiles of all sizes and shapes, but specializes in producing ultra-thin products. In between, they are offering one-stop solutions from the extrusion of raw materials through surface treatment including quality control, packaging, shipping and tailored-made solutions like design, manufacturing and logistics and become a perfect business partner for manufactures and building companies.

FAQs

Q: What types of aluminum profiles can be processed by CNC?

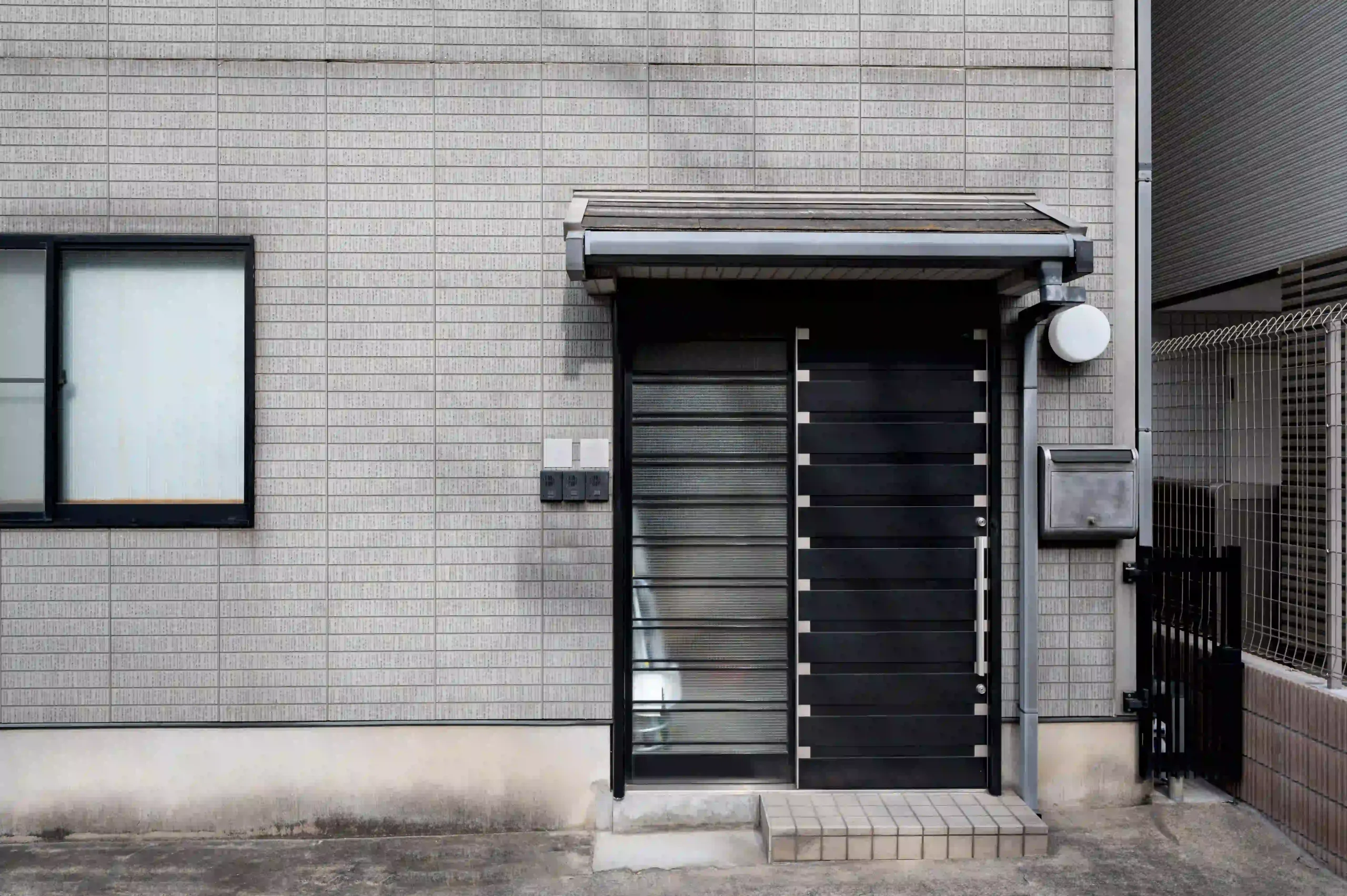

A: Most aluminum profiles can be CNC machined, including architectural elements in building construction (e.g., windows and doors), automotive parts, and consumer goods (e.g., frames for furniture).

Q: How does CNC machining prevent the softness of aluminum?

A: High-speed cutters and proper cooling systems (compressed air or coolant) are employed in CNC machines to prevent deformation, burrs, or wear on tools while cutting aluminum.

Q: Aluminum is employed in prototyping with CNC machining; why?

A: Aluminum is cheap, fairly easy to cut, and also permits rapid prototyping. It also provides a good strength-to-weight ratio for proof-of-concept test purposes, as well.