Many skilled individuals use heat to bend aluminum pipes and create exact curves and angles in their workmanship tasks. The process involves heating the aluminum pipe to gain flexibility, so it can bend without cracking. It has to be done carefully because heat can weaken the structure of the pipe.

Because it has a lower melting point than most other metals, it becomes very important to control the heat input while working with this metal. Use a controllable heat input and gradually increase it until it can work the aluminum. This will help ensure that the pipe retains its strength while being bent.

When considering this approach for your projects, checking out choices from trusted vendors such as Xihui Factory could offer you top-notch aluminum pipes, ideal for bending tasks.

What Tools Are Required for Bending Aluminum Pipes with Heat?

To properly shape aluminum pipes with heat treatment techniques, requires the use of various specialized tools.

- Heat Source: A propane torch or an induction heater can be used to apply consistent heat. Ensure that the heat source allows for precise temperature control to prevent overheating.

- Bending Jig or Form: This tool helps maintain the desired shape of the pipe during bending. It provides support and ensures uniformity in bends.

- Temperature Gauge: A thermometer or infrared temperature gun is crucial for monitoring the pipe’s temperature, ensuring it reaches the optimal level for bending without exceeding safe limits.

- Protective Gear: Safety goggles and gloves are essential when working with heated materials to protect against burns and eye injuries.

- Cooling Medium: After achieving the desired bend, rapidly cooling the pipe using water or air can help set its shape and prevent further deformation.

If you’re interested in getting these tools or top-notch aluminum, you should contact Xihui for details on what they have available.

Make sure to use these tools to make bending easier and ensure your aluminum pipes take on the exact shapes required for your projects without any issues. For a range of flexible aluminum piping options ideal for construction purposes,

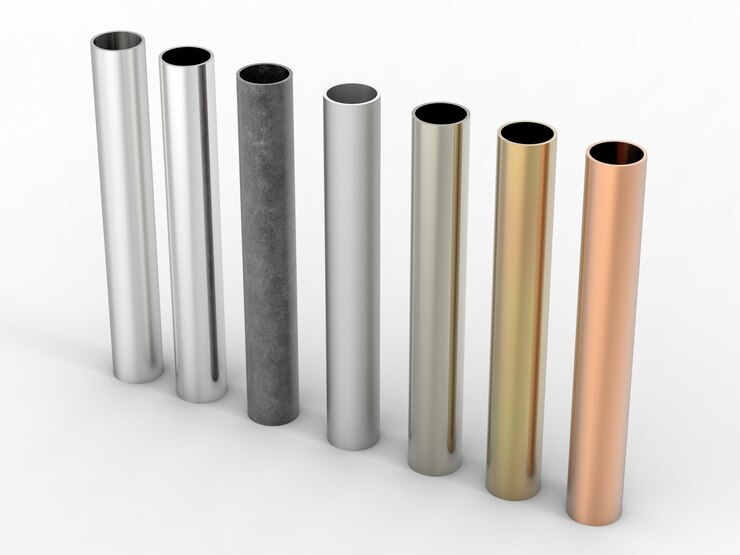

How Do Different Alloys Affect the Bending Process?

When dealing with aluminum tubes, it is important to take into account the alloy type being used because different alloys have levels of flexibility and durability characteristics that impact how they can be bent. Aluminum alloys are usually classified by series numbers, like 3000s, 5000s, and 6000s, each having features affecting their bending abilities.

- 3000 Series: Known for its good corrosion resistance and moderate strength, this series is relatively easy to bend. It’s often used in applications where flexibility is a priority.

- 5000 Series: This alloy offers higher strength and excellent corrosion resistance, making it suitable for more demanding applications. However, its increased strength can make bending more challenging without proper heat application.

- 6000 Series: Combining good mechanical properties with formability, this series is versatile and widely used in construction. It can be bent effectively with heat but requires careful handling to prevent cracking. For industrial applications requiring high-quality aluminum pipes, consider exploring Versatile Aluminum Round Tubes.

Knowing the properties of each type of metal is essential when choosing the appropriate alloy for your specific bending requirements. For purposes that demand top-notch aluminum tubing quality, opt for Versatile Aluminum Round Tubes.

What Are the Steps to Successfully Bend an Aluminum Pipe?

Accomplishing a bend in an aluminum tube requires a methodical strategy to guarantee accuracy and prevent any potential harm.

- Select the Right Alloy: Choose an aluminum alloy that suits your project’s requirements in terms of strength and flexibility.

- Prepare the Pipe: Clean the pipe thoroughly to remove any debris or contaminants that could interfere with the heating process.

- Heat Application: Use a temperature-controlled heat source to warm the pipe gradually. Monitor the temperature closely using a temperature gauge to ensure it reaches the optimal level for bending.

- Bend Using a Jig: Place the heated pipe into a bending jig or form to guide it into the desired shape. Apply steady pressure to achieve a uniform bend.

- Cool Down: Once the desired shape is achieved, cool the pipe rapidly using water or air to set its form and prevent further deformation.

By following these guidelines and instructions provided here step by step, with attention to detail, you can successfully achieve accurate bends in aluminum pipes without compromising their structural strength and durability. If you require any help or seek top-notch materials of quality, please don’t hesitate to get in touch with Xihui Factory for expert advice and access to premium products.

How Can You Ensure Qualityand Safety During the Process?

Making sure that quality and safety are maintained while shaping aluminum pipes using heat requires attention to several important factors.

- Material Selection: Start by selecting the appropriate aluminum alloy for your project. As discussed, different alloys have distinct properties that affect their bending capabilities. Ensure that the chosen alloy meets both strength and flexibility requirements.

- Proper Tool Usage: Use proper tooling, such as a temperature-controlled heat source and a bending jig, for accuracy. The accurate control of temperature prevents overheating and weakness in the pipe.

- Safety Gear: Use safety goggles and gloves to help prevent burns or eye injuries resulting from heated material.

- Controlled Environment: The bending shall be performed in a controlled environment to prevent drafts or moisture from affecting heating and cooling.

- Monitoring & Inspection: Regularly monitor the pipe’s temperature using a thermometer or infrared gun. Inspect the pipe for signs of cracks and other structural flaws after bending that may compromise its integrity.

Following these instructions can significantly improve the quality and safety of the bending process. If you need top-notch aluminum pipes for such purposes, Xihui Factory provides a variety of products that adhere to industrial norms.

Additional Resources for Further Guidance

Professionals seeking to enhance their skills in shaping aluminum pipes using heat can explore available resources.

Industry Workshops Note: Taking part in workshops or seminars dedicated to metal fabrication offers experience and valuable knowledge shared by industry professionals.

Online tutorials are widely available on websites and platforms, guiding bending aluminum pipes using a range of techniques—from the basics to more advanced approaches.

Be sure to refer to manuals that correspond to your equipment or tools, as they typically provide thorough instructions and safety precautions.

Supplier Assistance: Interacting with suppliers, such as Xihui Factory, can offer resources and assistance for their merchandise to ensure you receive expert guidance as required. If you need information or additional help, contact Xihui may be a good idea.

Utilizing these resources can help you improve your abilities and achieve results in your aluminum pipe bending projects that require heat application.