Aluminum pipe is one of those many underappreciated materials as most think of it in terms of basic plumbing. However, with a variety of uses beyond those, this versatile material becomes indispensable to many industries. From lightweight transportation systems to structural design, aluminum pipes have been the reliable solution to many needs. In this blog, You will discover how you can make use of aluminum pipes and some of the unique properties that make it so ideal for many uses.

The Flexibility of Aluminum Pipe

The mention of the word aluminum instantly brings to mind a lightweight metal used to manufacture cans or make foil. This very product when manufactured into a pipe format is found to be very useful. Properties that make aluminum such a popular material to make a wide variety of products make it a very good choice for piping. Whether it’s its lightweight nature, strength, corrosion resistance or excellent thermal conductivity, aluminum pipe offers numerous benefits that other materials may struggle to match.

Dispelling the Myth: Aluminum Beyond Basic Plumbing

The general impression about aluminum pipes is that they serve only in plumbing systems. While aluminum indeed works well for water and gas lines, its applications go way beyond this sphere. In general, aluminum pipes are highly valued in those industries where lightweight materials are required without compromising strength or durability. Its resistance to corrosion in combination with the high strength-to-weight ratio makes aluminum appealing for many high-performance environments.

Industrial Applications

From aircraft to construction sites, aluminum pipes serve vital functions in many industries. In fact, the understanding of the use of this material in various industries can portray a comprehensive range of its potentials.

Transportation: From Fuel Lines to Aircraft Structures

The transportation industry is obliged to use an aluminum pipe. Because of its lightweight nature, it is ideal for car, truck and plane fuel lines, which is one of the prime options to reduce weight and thus develop higher fuel efficiency. Pipes made of aluminum find their application in aircraft manufacturing: hydraulic systems, air conditioning and fuel lines among others. It helps to satisfy the high-performance requirements of vehicles while reducing the overall weight of the structure.

Hydraulic Systems: Tapping into Aluminum’s Lightweight Strength

Hydraulic systems provide another sphere of application where aluminum pipes are used because they boast superb strength and are lightweight. It could be machinery, industrial equipment or even vehicles, aluminum pipes can surely take high pressure without the fall in integrity. It makes them ideal for a system that works on fluid movement due to pressure, such as construction machinery or industrial hydraulic presses.

Temperature Control: The Role of Aluminum in Thermal Management

With high thermal conductivity, aluminum is suited for applications highly involving the regulation of temperature. Besides that, several heat-transferring applications involved in industries use aluminum pipes, which include systems of refrigeration, HVAC and heat exchangers. They can conduct and dissipate heat sufficiently and are indispensable in heating and cooling processes both commercially and industrially.

Diverse Applications

Aluminum pipes are certainly utilized beyond only a few key industries. Several of the more common and specific uses are detailed in the following sections below.

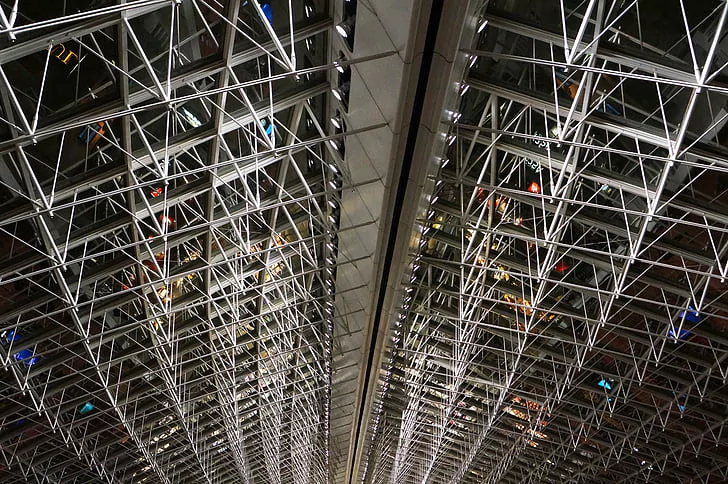

Structural and Framing: Support for a Multitude of Designs

Aluminum pipes are also used in structural applications where their strength and lightweight nature are essential. You’ll often find aluminum pipe framing used in construction, especially in buildings that require custom designs or lightweight structures. Aluminum framing is frequently seen in temporary structures, scaffolding and frames for industrial machines, offering the support needed while maintaining flexibility in design.

Fluid and Gas Transport: An Efficient Conduit

Other massive uses of aluminum pipes are found in transporting fluids and gases. The excellent resistance to corrosion and withstanding pressure makes aluminum ideal for systems carrying everything from water and oil to air. Be it water, oil or air, aluminum pipes ensure that fluids flow efficiently without the risk of leaks or degradation over time.

Electrical Applications: Beyond Basic Wiring

Aluminum also finds a wide variety of applications in electrical uses, especially when weight sensitivity is in question. In some electrical systems, especially the higher-scale power generation and transmission, conduits for wiring are in the form of aluminum pipes. For such applications, these aluminum pipes mean an economical yet reliable method of cable protection and conduction of electricity under different environmental conditions.

Aquatic Environment: Corrosion Resistance in Action

The marine environment is highly corrosive and it is pretty harsh on the material used in boats, ships and offshore platforms. Among all, the aluminum pipes are largely well-known for their resistance to corrosion, particularly in seawater. This makes them an ideal choice for a wide variety of applications in marine, including in exhaust systems, hull structures and water pipelines.

Types – Special and Their Applications

Not all aluminum pipes are the same. With different grades, there come a few properties that have made each good for certain purposes. A few of the common types and places where they excel will include the following:

5052 Aluminum Pipes: Corrosion Resistance is Key

5052 aluminum pipes are especially known for their excellent corrosion resistance, which makes them very suitable for applications in marine and chemical processing industries. These pipes are really very good in saltwater conditions, thus offering durability and reliability in severe conditions.

5083 Aluminum Pipes: Strength and Durability in Marine Settings

The 5083 aluminum pipes also show excellent feasibility in marine applications due to their high strength and resistance to corrosion. They find application in shipbuilding and offshore platforms where strength and durability are the main concerns.

5086 Aluminum Pipes: Stability in Aquatic and Industrial Environments

5086 Aluminum Pipes share numerous similarities with the 5083 series, except that it is somewhat stronger and suitable for heavy-duty applications in a marine environment. These pipes also apply to industrial contexts where strength with durability is a pre-requisite in the construction of pressure vessels and tanks among others.

6061 Aluminum Pipes: Structural Strength for Aerospace and Beyond

6061 aluminum pipes are one of the most versatile, balancing strength and work-ability. These pipes find wide applications in aerospace, automotive and structural purposes where high strength with lightweight properties is required.

6063 Aluminum Pipes: The Go-To for Architectural Design

The architectural uses of 6063-grade aluminum pipes can include a wide range of applications, such as window framing and various door and structure applications where esthetic appeal becomes as important as durability. Thus, 6063 piping can be easily manipulated to shape, easily anodized and often used in architectural design.

7075 Aluminum Pipes: Aircraft-Grade Strength

7075 series aluminum tubes have the best strength-to-weight ratio and therefore are mainly applied within the aerospace industries. It’s perfect for high performance really worthy vehicles such as aircraft where weight on every ounce counts.

Shapes And Manufacturing

These are available in several shapes to meet various requirements. The manufacturing process, especially the extrusion method, ensures that a wide range in sizes and shapes-from round, square to rectangular pipes-can be possible in the case of an aluminum pipe.

The Extrusion Process: Shaping Aluminum Pipe

Extrusion is one of the most important processes to give shape to aluminum pipes. Here, heated aluminum is forced through a mold that produces pipes in desired dimensions. It is fast and allows high-quality maintenance during mass production.

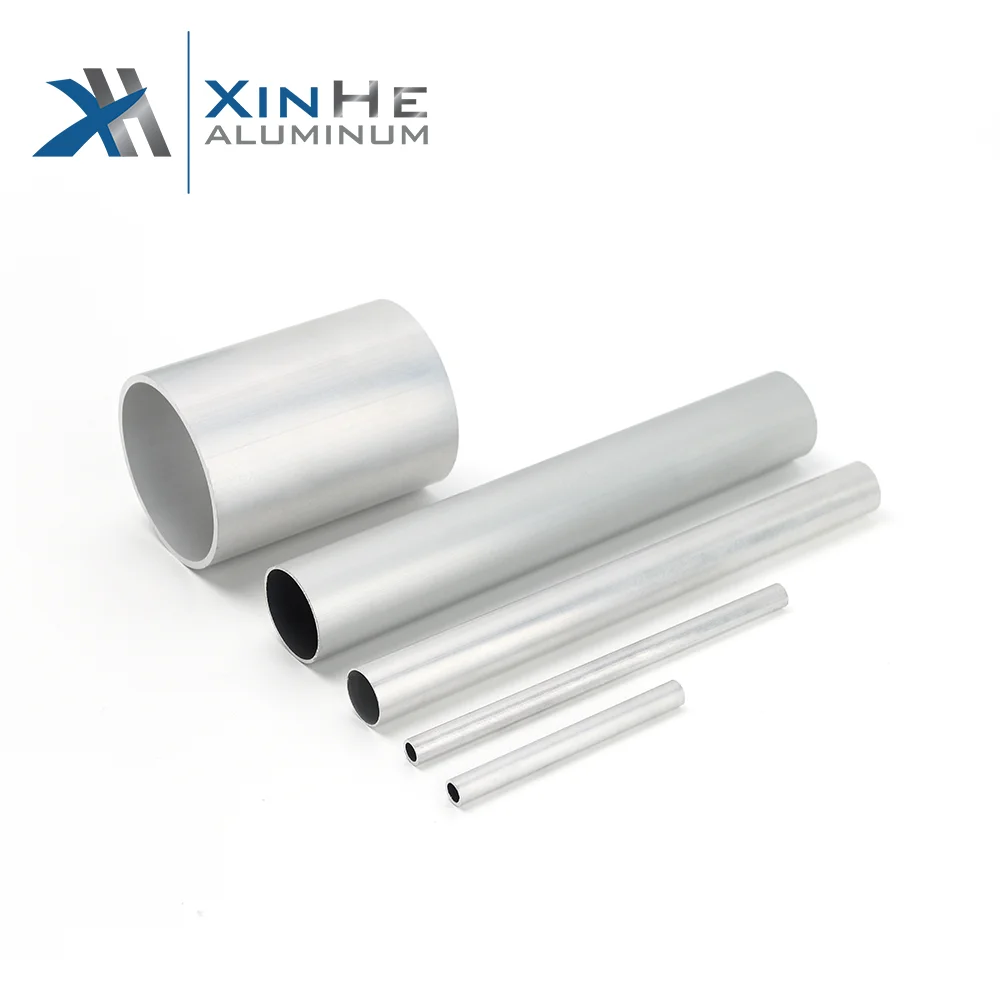

Round Pipes: The Most Common Choice

Round aluminum pipes remain the most used due to the versatility they portray. They have applications in nearly all uses-from the transportation of fluids to structural supports-because of their balanced strength and ease of handling.

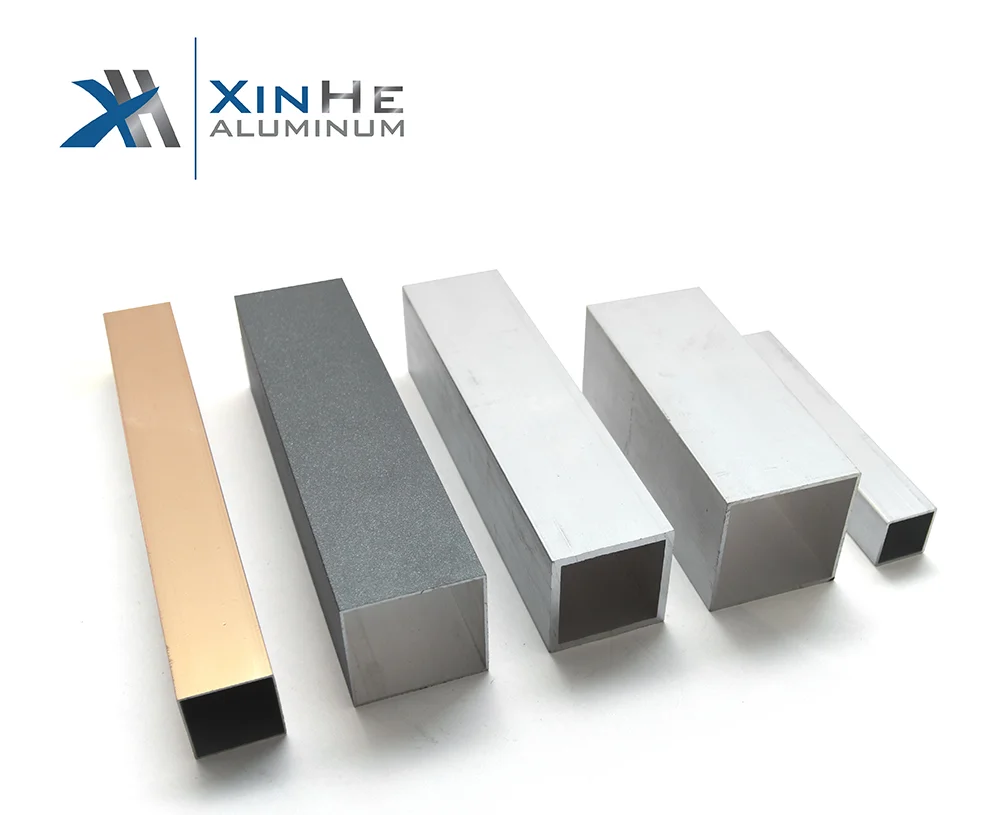

Square and Rectangular Pipes: High Strength for Specific Uses

Square and rectangular aluminum pipes can lend added strength to the right application. More importantly, they are great for structural and framing projects. Their geometry allows them to lend amazing support for several designs and in certain applications can be more space-efficient.

How to Choose the Right Aluminum Pipe

When choosing an aluminum pipe for your application, there are a couple of factors you will want to consider.

Performance Specifications: Pressure, Bend Radius and More

The type of aluminum pipe you will choose depends on the specific performance that your project requires. You may consider pressure capacity, bend radius and flexibility among other factors relevant to your purpose.

Material Properties: Formability, Weldability and Corrosion Resistance

Properties, of course, vary depending on the aluminum alloy in question. Factors to consider include the formability—that is, how easily the pipe can be shaped—weldability, and resistance to corrosion when selecting the correct pipe for the intended use.

Material Type Matching Application

The intended application of the aluminum pipe should guide your decision. Different industries and environments have different requirements, such as increased strength, flexibility or corrosion resistance. Matching the material to your application is crucial for ensuring long-lasting performance.

XiHui Aluminum: Your Trustful Aluminum Tube Supplier

Looking for high quality aluminum pipes for your project? For years, XiHui Aluminum Co., Ltd. has been one of the trusted suppliers in the industry. With a wide variety of options for aluminum pipes serving different applications, they can surely satisfy the demands of its customers in constructions, aerospace and marine industries.

FAQs

1. Can the aluminum pipe be used for water plumbing?

Though not typically used for regular plumbing since it reacts with water, it does find use in water line systems where its lightweight and resistance to corrosion is an advantage.

2. Can aluminum pipes be welded?

Aluminum pipes are weldable but it requires very specific techniques and equipment.

3. Why is aluminum pipe preferred for marine applications?

Due to their great corrosion resistance, plus their light weight and strength characteristics make them very suitable for the most challenging conditions in saltwater.