Aluminum is often viewed as a lightweight substance, however, its versatility goes beyond that perception. Aluminum profiles possess a blend of characteristics that render them a preferred choice across various industries. In this blog post, we’ll explore the durability of aluminum profiles and how they manage to strike a harmonious balance between being light in weight and robust in strength.

Introduction to Aluminum Profile Strength

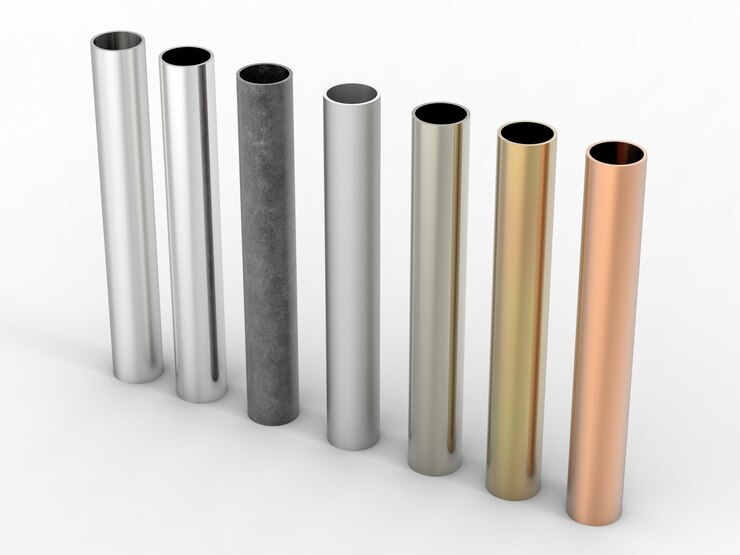

Aluminium is a material in its natural state and offers many advantages for various applications due to its abundance as the most prevalent metal and the third most common element in the Earths crust. Moreover, it is non-flammable by nature. Has excellent corrosion resistance. When aluminum is formed into profiles through the extrusion process, it not only retains its intrinsic properties but also provides design flexibility for crafting products that are both sturdy and lightweight.

The Versatile Nature of Aluminum

Aluminum’s ability to be shaped easily into forms without compromising its strength makes it ideal for projects requiring intricate designs. Moreover, its innate resistance to corrosion makes it perfect for conditions. Therefore you can count on your aluminum structures to endure for a period with little upkeep required.

The Advantage of Extrusion

Extrusion proves to be an effective method for producing lengthy profiles featuring both straightforward and intricate contours. Its integration with aluminum offers an array of benefits that make it a cost-efficient choice for designers alike. The versatility of aluminum allows for the creation of a range of products through the extrusion technique. From basic frameworks to detailed components.

Key Factors in Aluminum Profile Strength

When considering aluminum profiles, it’s essential to grasp the elements that influence their durability. It’s not about the base material but also how it performs and can be improved. With an understanding of such factors, one can comprehend the reasons behind the widespread popularity of aluminum profiles.

Strength-to-Weight Ratio

Aluminum offers a benefit in terms of its impressive strength-to-weight ratio where it outweighs materials like steel by being significantly lighter while maintaining strong durability levels of up to 60%. This feature simplifies the handling and transportation of aluminum goods without sacrificing their performance capabilities.

Corrosion Resistance

While rust and deterioration normally happen with steel, aluminum naturally protects against corrosion. Its naturally formed oxide layer protects it against further corrosion damage outdoors or in the marine environment because of high humidity or regular water exposure. This makes it a smart choice for long-lasting structures, which will save your time and money in the long run.

The Role of Surface Treatments

Aluminum easily accepts surface treatments such as anodizing and powder coating which can boost its resistance to corrosion and enhance its performance overall. Anodizing can introduce an element with a variety of colors while powder coating offers a thicker and longer-lasting finish. These choices allow you to personalize the appearance and quality of your aluminum profiles for functionality.

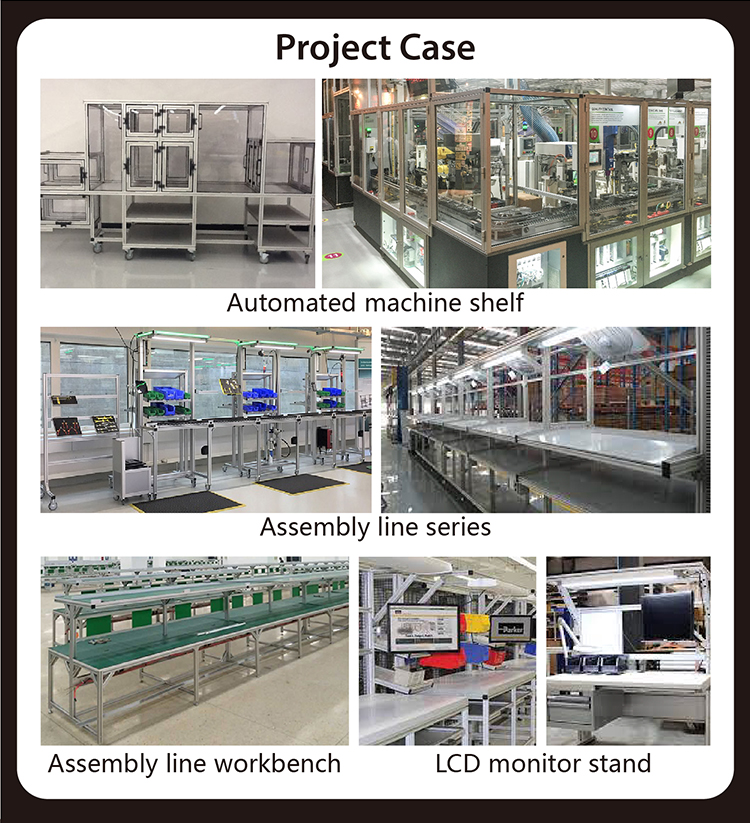

Applications Demonstrating Aluminum Profile Strength

Aluminum profiles have a range of uses across various industries due to their versatility and efficiency in different settings. From construction projects to everyday consumer goods. Highlighting the extent of their functionalities.

Construction and Architecture

In construction and architecture fields, Aluminum profiles are widely employed for creating skylights, canopies, roofs and fences. The building sector heavily relies on aluminum items. These frameworks demand materials that are both lightweight and durable and aluminum fits the bill perfectly. Aluminum’s ability to resist corrosion is particularly beneficial for uses ensuring longevity and visual attractiveness of the structures over time. Moreover, aluminum profiles provide the flexibility to craft designs that’s both practical and visually appealing, catering to a range of requirements within the architectural industry.

Automotive and Transportation

In the transportation sectors, aluminum profiles are utilized to lower vehicle weights and boost efficiency levels effectively. It’s common to see aluminum in vehicle parts such as cross members, subframes trim pieces and various accessories. This not only enhances fuel efficiency but also elevates the overall performance of vehicles. Moreover, the corrosion resistance factor is crucial for vehicles exposed to elements. Furthermore aluminum finds its place in buses, utility trailers, off-road vehicles, aircraft, boats and docks, showcasing its versatility in the realm of transportation.

Industrial Applications

Aluminum profiles are frequently used in environments for frameworks and structural supports due to their lightweight properties that simplify assembly and installation processes. They are also commonly found in assembly line structures. As enclosures for equipment and testing machine supports. The thermal conductivity of aluminum is especially beneficial for creating heat sinks in devices. The diverse range of uses in settings demonstrates the versatility of aluminum profiles.

Consumer Products

Aluminum extrusions are commonly used in a variety of consumer goods such as camping chairs baseball bats golf clubs bicycles cookware and furniture due to their affordability and versatility. These instances highlight the utility and cost-effectiveness of aluminum profiles in products for consumers.

Aluminum Profile Design and Customization for Optimal Strength

When you work on projects using aluminum profiles as the material in your design process, it’s crucial to think about how you can make the most of their unique properties for your specific needs. The customization possibilities and design choices are essential in ensuring that your project achieves the desired level of strength and performance. Gaining a grasp of these choices will enable you to fully leverage the potential of this versatile material.

Malleability and Design Flexibility

Aluminum flexibility offers a range of design possibilities by allowing easy shaping into different forms and dimensions to tailor structures to your unique requirements. Be it for straightforward or intricate designs, aluminum profiles can adapt to diverse shapes effectively to fulfill your project specifications while ensuring stability and durability.

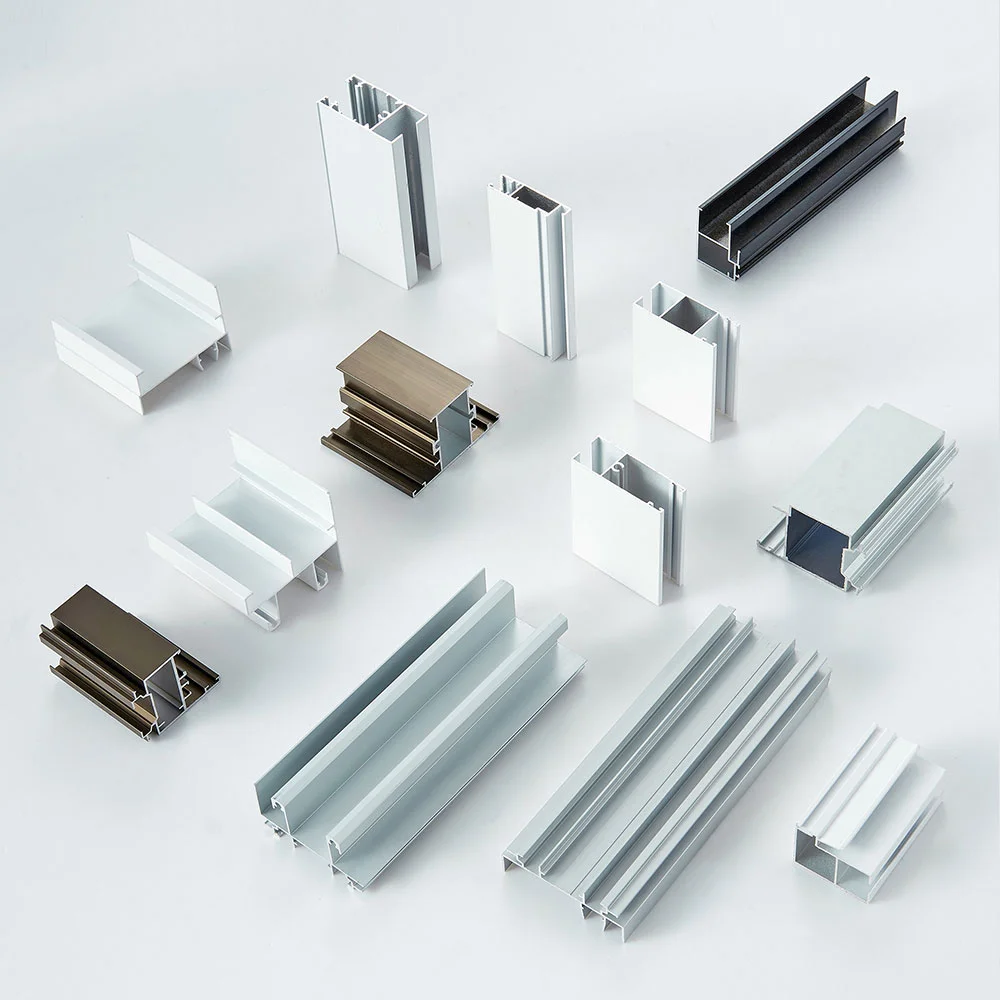

Customization Options

Aluminum profiles offer a range of customization options to meet the specific needs of your project. They come in various shapes and sizes with different finishes available for creating distinctive and adaptable structures Surface treatments, like anodizing and powder coating not only enhance the look but also improve functionality. You can also add color and texture variations to tailor your aluminum profiles to your liking

Standard Dimensions

When it comes to aluminum profiles sizes and dimensions options are plentiful – from custom measurements to ones like 3030 and 4040 up to 100100 sizes, commonly used in various projects and product design tasks. You’ll want to pay attention to the interior hole size of these profiles, as it plays a crucial role in ensuring smooth assembly processes. Understanding these dimensions is key in choosing the right profiles for your projects, whether you’re building structures or crafting new products.

Xihui Aluminium Co. Ltd.: A Reliable Supplier

Founded in 1993 Xihui Aluminium Co. Ltd. is a producer of top-notch aluminum extrusion profiles. With more than three decades of experience, the company focuses on crafting slim profiles and operates a contemporary facility with 15 automated extrusion lines, generating 20 thousand tons per year. Catered to customers in 120 nations, Xihui provides a variety of profiles for purposes such as doors, windows, kitchen cabinets and household embellishments. Xihui offers a range of finishes, like silver and powder coatings to meet your aluminum profile requirements with dependable and personalized solutions.

FAQs

Here are some common queries people often ask about the durability of aluminum frames.

1. Do aluminum profiles have the same strength that steel profiles do?

Nope! Aluminum profiles may not be as sturdy as steel ones, however their strength-to-weight ratio is higher which means they are much lighter compared to steel profiles They are robust enough for a variety of uses and their lightweight quality makes them easier to manage and transport.

2. Why are aluminum profiles able to maintain their strength while still being lightweight?

Aluminum profiles are durable because they have a balance of strength and weight and can resist corrosion while also being able to undergo treatments to improve their lifespan.

3. Is it possible to utilize aluminum profiles in challenging conditions?

Aluminum profiles have corrosion resistance and can receive additional protection through methods, like anodizing and powder coating which makes them well-suited for challenging conditions.

4. How does the design of aluminum profiles enhance their strength characteristics?

Aluminum profiles can be tailored to enhance strength for uses by incorporating versatile designs that balance both structural durability and visual attractiveness.