Aluminum alloy has become a go-to material for CNC machining, the perfect blend of lightness, strength, and corrosion resistance. Being so versatile, manufacturers can make precise parts in various industries in the construction, automotive, and electronics industries. Find out how aluminum alloy, combined with CNC technology, reaches its full efficiency, saves money, and offers customized solutions for specific applications.

Why is Aluminum Alloy an ideal material to be subject to CNC Processing?

Aluminum alloy is most commonly used in CNC machining because it can be used across various industries like construction and automotive, for light weight and corrosion problems – hence making it one of the best options for creating accurate parts through CNC processing.

Advantages of Using Aluminum Alloy

Using aluminum alloy for CNC machining is advantageous in that it is light but durable. This makes it possible for manufacturers to machine components without too much weight, which is an important factor for applications such as aerospace and automotive production, where weight must be kept to a minimum. Aluminum alloys provide corrosion protection that guarantees durability and long life of final products.

Also, aluminum alloys are very malleable that facilitates the creation of complex shapes and intricate designs which can just be achieved by employing the technique of CNC machining. Such malleability facilitates the customization of the parts to obtain specifications in design without the sacrifice of functionality and quality.

Common Applications of Aluminum Alloy in Various Industries

Aluminum alloy is applied widely in industries for various uses. In the construction industry the material is applied widely in the manufacture of sliding doors and windows casement doors and windows. Even in the construction of advanced and robust curtain walls, it also adds beauty to buildings both structurally and aesthetically.

In the age of cars and technology, aluminum alloys are at the forefront of creating light-weight car parts that enhance fuel economy without sacrificing performance and safety! And that is not all, the electronics industry also values the way aluminum’s notch thermal conductivity helps in heat sinks and cooling systems!

How Does CNC Processing Enhance Cost Effectiveness?

Use of CNC processing is imperative towards increasing cost-effectiveness through optimization of the production processes and minimizing wastage of resources. CNC equipment is based on the functionality of the most advanced technology for the purpose of facilitating control of manufacturing processes output.

Precision and Accuracy in Manufacturing

With CNC processing, precision and accuracy are guaranteed in component manufacturing in production environments. The precise process guarantees wastage minimization and less error during production. Manufacturers’ quality standards maintained in extended production runs result in reduced reprocessing or material rejection expenses.

The capability to create items of precise measurements also translates into there being very little human interference or realignments, throughout the entire manufacturing process thus keeping labor costs at a lower level while still maintaining higher levels of quality.

Automation and Its Effect on Manufacturing Expenses

Use of CNC machine automation capabilities plays an important role in adding to the cost of production activities by facilitating manufacturing operations through the employment of machines running continuously without humans having to initiate them or make adjustments, thereby accelerating efficiency increased throughput rates, and reduced product lead times.

Secondly, automation lowers the need for skilled labor in specific work which ultimately leads to lower operating costs. Businesses are able to optimize their workforce better by assigning them skill-based work and reserving mundane or repetitive work for automation.

Why is Customized CNC Processing Ideal for Businesses?

Customized CNC machining benefits business organizations by enabling them to produce answers most ideally suited to their requirements. Focus on individualization helps business organizations achieve cost-effectiveness and enhanced operating efficiency.

Customized Solutions to Particular Needs

Selecting CNC machining gives you the liberty of creating parts to precisely suit your own specifications and requirements. Advanced-level customization provides each part with detailed design to suit the exact requirements of your project. If you’re engaged in a development project or an industrial or commercial project, customized CNC machining provides an opportunity to create parts that integrate within your architectural design and operational needs.

Apart from that, personalized solutions offer the factor of flexibility in order to accommodate special features or design aspects that give your products an advantage over the market place scene.Another aspect is the fact that customized solutions not just offer a nicer appearance for your products but also offer optimum performance and efficiency.

Long-term Cost Savings with Customization

Selecting CNC machining saves your business a significant amount of money in the long run. Creating parts that are uniquely developed to fit your requirements eliminates wastage and eliminates rework or re-machining. This precise process allows you to utilize the material you need and saves you funds on wastage material usage fees.

Besides, bespoke CNC machining enables you to optimize production processes by omitting steps or modifications. This optimization results in lower labor costs and shorter production time that allows you to produce products earlier and at lower costs.

How Can Businesses Optimize the Aluminum Alloy CNC Processing?

In an attempt to tap into the advantages of aluminum alloy CNC machining to this level, prospective organizations need to make sure they concentrate on streamlining their processes and using material in the right manner. Implementing strategies assists businesses further in reducing costs and increasing productivity overall.

Process Optimization Techniques

Improving the CNC processing process entails locating areas for improvement in an attempt to increase efficiency and lower costs effectively. Among the guaranteed ways is integrating new software solutions capable of real-time monitoring and analysis of production processes. They give you data about machine performance that allows you to locate bottlenecks or inefficiencies and make knowledgeable decisions to improve processes.

For using the production processes in an efficient manner to get the maximum output and reduce errors at the time of utilization of CNC machines, training sessions for the employees are essential.

Rational Material Utilization for Cost Savings

Material optimization and maximizing the cutting paths will enable the companies to reduce wastage and use the resources to the fullest. With the help of software, the location of materials can be optimized to achieve the minimum amount of scrap during machining.

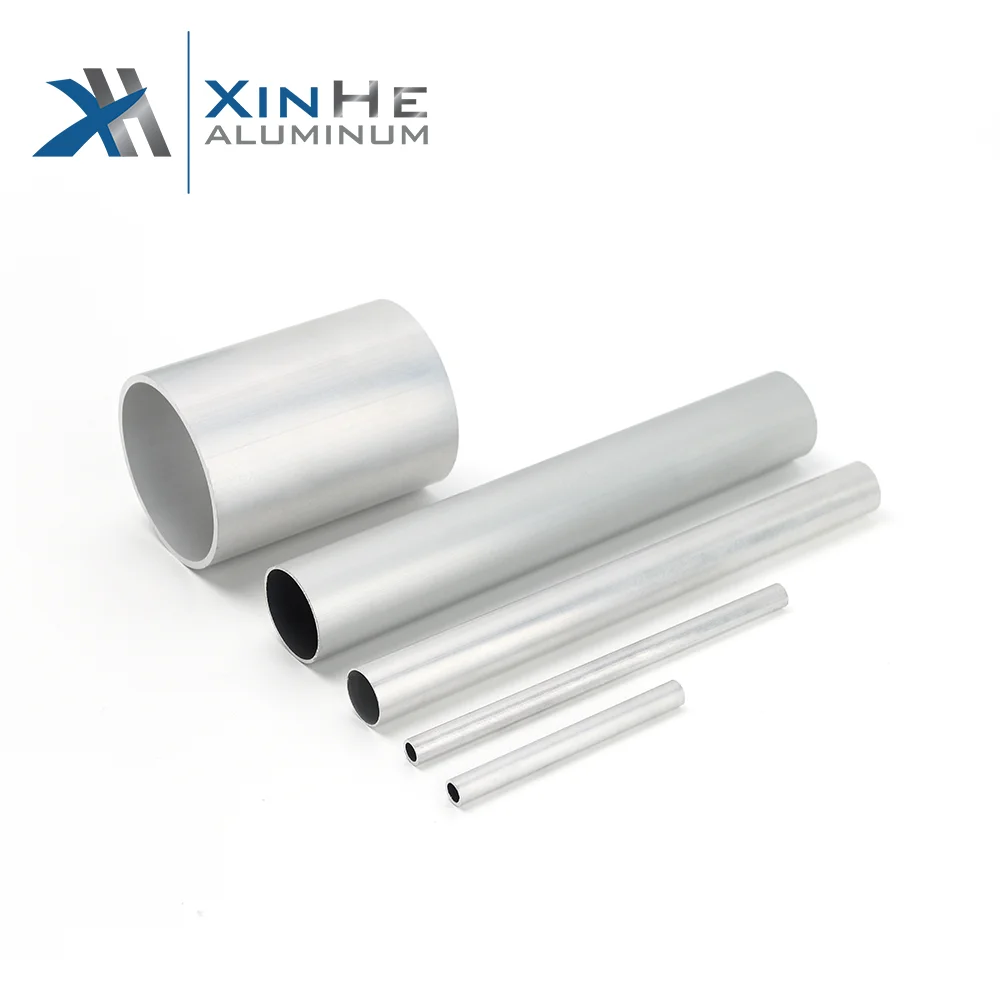

Aside from that, choosing the right grade of aluminum alloy per project need may be a considerable cost factor when it comes to material cost. Our wide selection of products includes the availability of anywhere between 090 mm and 250 mm and finishes such as clean anodized silver and certain powder coatings all tailored to order certain specifications but affordable.

By concentrating on process optimization and minimal material usage, companies are able to gain maximum benefit from the advantages in terms of tailored CNC milling of aluminum alloys. These measures not only make them cost-effective, but overall operating efficiency enhances setting businesses up for success even with poor market performances.

How XiHui Aluminium Co., Ltd, Distinguishes Itself as a Supplier

XiHui Aluminium Company is a leading aluminum manufacturing and supplying company with emphasis on quality and innovation. Its high-tech factory is equipped with advanced anodizing and powder coating machinery that is used to create high-quality, eco-friendly products. They provide ODM & OEM services with customized solutions from design to packaging. Their wide range of products caters to architects and contractors with profiles appropriate for buildings and business ventures. They offer end-to-end support services to distributors and builders for a hassle-free buying experience. Choose XiHui for premium aluminum profiles and world-class support for industries.

FAQs

Q: How much does custom aluminum CNC machining cost?

A: It depends on design complexity and volume but is value-optimized.

Q: Is the quality of aluminum parts repeatable?

A: Yes, accurate machining ensures the quality is repeatable and high.

Q: Can CNC machining accommodate complex aluminum designs?

A: Yes, CNC machining is capable of giving high precision to special and complicated designs.