Selecting the correct CNC machining supplier in China can really determine your product quality and business success. Right from the choice of material to accuracy standards, there are various aspects in the final product. This blog illuminates you on the major aspects to be researched, ranging from technology, experience, certifications, and communication to assist you in selecting a good partner for your CNC machining requirements.

What Determine the Quality of CNC Machining in China?

When considering a CNC machining facility in China, there are critical factors that may affect the general quality of the final product. It’s vital to understand these factors to make an informed decision and ensure that your needs are met precisely and efficiently.

Material Selection and Its Influence

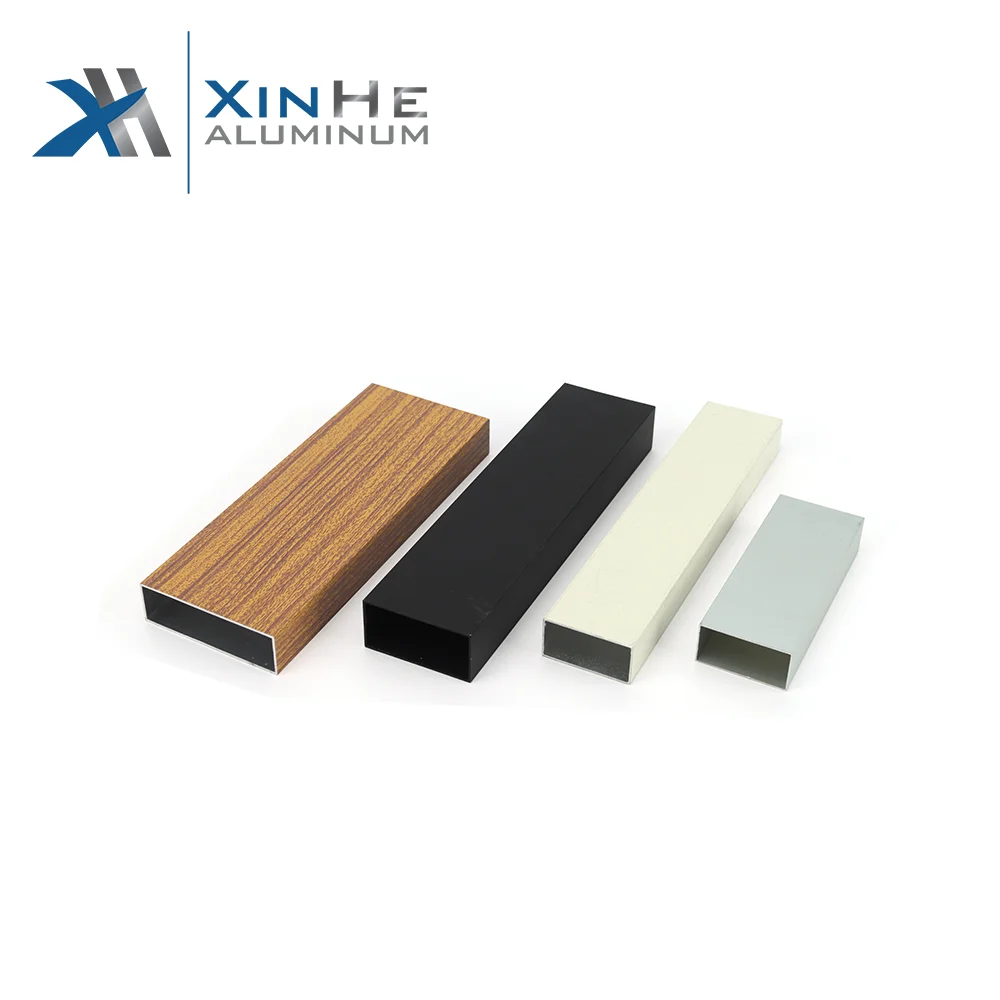

Material selection is a factor to be considered when it comes to CNC machining part quality and performance because of the characteristics of materials involved. Like aluminum alloy, it can have a substantial impact on these factors. Characteristics of different materials influence machining processes as well as longevity and suitability for specific uses. It is worth approaching a CNC machining plant on the grounds of their material-handling experience and their capability to suggest the most suitable alternatives for your individual needs.

Precision and Accuracy Standards

In CNC machining workmanship is important to success the quality of your products can be largely decided by standards maintained by a plant seek factories that follow accuracy standards and possess state-of-the-art equipment capable of holding close tolerances this ensures that every part is made with consistent quality reducing errors and improving overall performance.

Technological Capabilities of the Factory

The technical capabilities of a CNC manufacturing factory reflect whether it can produce quality products cost-effectively and effectively through the use of machines and high-tech technologies in its production. In evaluating project work partners, don’t forget to ask about tools utilized software systems installed and how they manage intricate tasks.

How Does Cost Come into Play in Selecting a CNC Machining Factory?

Select a CNC machining factory in China not based on cost but quality to get the best for your money while keeping costs at bay.

Evaluating Cost vs. Quality

When you are assessing suppliers for your needs or product buying needs and requirements, don’t forget to look beyond the price tag itself; look also at the general quality and level of the products they supply as well. Factories which say costs can sometimes cut corners on material quality or levels of precision in a bid to keep their prices low. This compromise may or may not be impacting your parts’ performance and functionality in a certain way. Balancing being frugal with quality is the key to go for suppliers with prices but a commitment to quality to creating high-quality goods.

Negotiating Terms with Suppliers

While negotiating with vendors is crucial in getting deals underway, make sure to tell them when to pay and receive deliveries from the CNC machining facility. And anything else they’re offering as well! Having that conversation makes everything clear to everybody and what everybody can look for in the future for both sellers and buyers engaging in the negotiations! It is necessary to have discussions on the terms so that your budget and what is available from the supplier are on the same page.

How Does Experience Affect a CNC Machining Factory’s Performance?

Experience is used here in calculating the success of a CNC machining facility keeping in mind the number of years in operation and the level of expertise and industry acumen employed.

Years of Operation and Industry Expertise

Years of functioning can give us an idea about how robust and dependable a factory is in its sector. An older factory has knowledge of a lot of experience about market scenario and desires of customers along with advancements in technology. It prepares them for anticipation of hurdles and taking corrective steps in due time.

Workforce Skills and Training

The training and education of factory workers play a role in the success of a factory as a whole. A trained workforce guarantees the completion of tasks with quality output. One needs to verify if the factory focuses on training programs for its employees to keep them abreast with the most advanced CNC machining methods.

Why is Certification Important When Choosing a CNC Machining Factory?

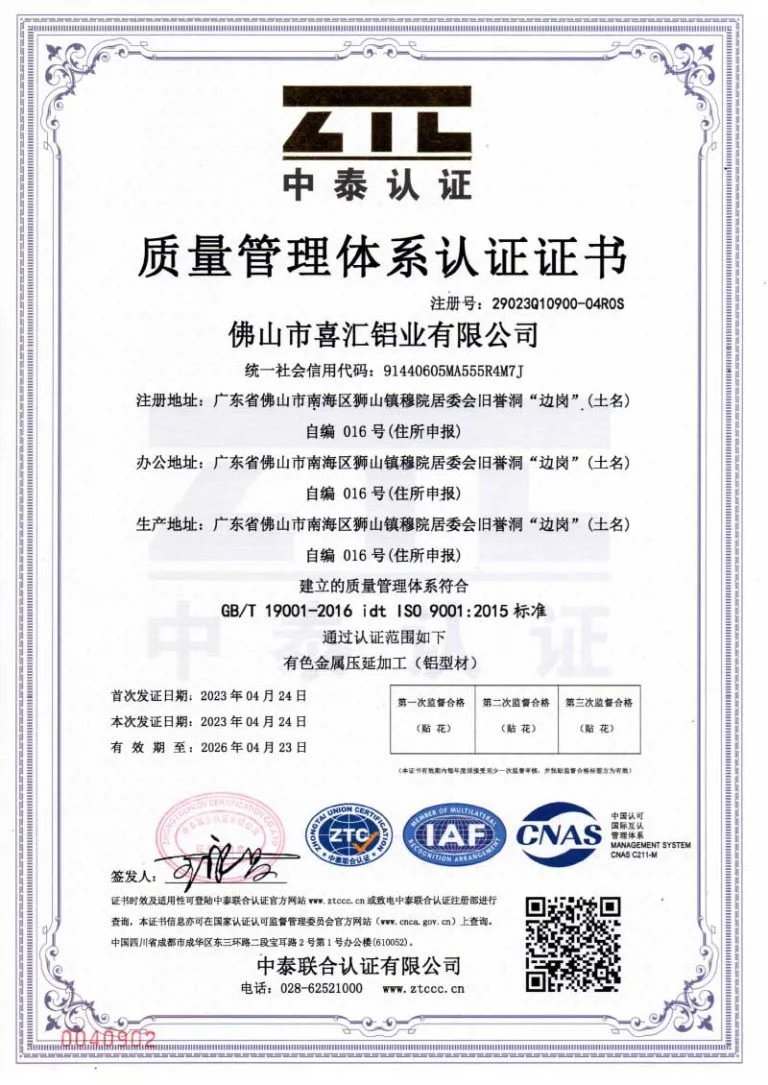

Certification is a way of expressing that a CNC machining factory follows high quality standards that depict their dedication to staying excellent in all business matters.

Standard Certifications to Look For

In choosing a CNC machining facility to work with, it is important to check for certifications like ISO 9001 or AS9100, because they depict compliance to international quality management standards leading to production processes and enhanced customer satisfaction.

Implication of Certification on Quality Assurance

Certifications help in ensuring quality standards are maintained in the production processes by creating organized methods of tracking activities and addressing any issues promptly to ensure continuity in manufacturing quality when selecting an accredited plant.

Knowing these facts helps you make well-qualified choices when selecting a CNC machining center in China. Taking into consideration aspects like material selection accuracy requirements, technical qualifications, level of experience, human resource skill set, and the aspect of being certified or not, you are guaranteed that the company you choose meets your requirements for excellence and reliability with each project.

XiHui Aluminium Co., Ltd: A Trusted CNC Machining Supplier

XiHui Aluminium Co., Ltd is a premier CNC machining supplier located in China specializing in aluminum alloy solutions with a track record of delivering quality and customer satisfaction. They provide best-in-class precision parts of the highest quality that meet industry standards and their experts and advanced technology guarantee the best outcomes. Through their customer service and global access for cooperation opportunities turn to XiHui Aluminium for reliable CNC services with an emphasis on good communication and affordable practices to cater to your unique needs effectively.

FAQs

Q: Is CNC in high demand?

A: Yes, CNC is very much in demand since the requirement for precision manufacturing is increasing in industries like aerospace, automotive, and electronics.

Q: Will I profit from using a CNC?

A: Yes, it is possible to profit with CNC through provision of machining services, production of specialized items, or sale of parts processed with CNC to industry or end-use markets.

Q: How accurate is CNC milling of aluminum parts?

A: CNC machining can achieve tolerances of up to ±0.001 inches with high accuracy for aluminum alloy components.