Challenges in Aluminum Extrusion Manufacturing

The world of metal manufacturing has long grappled with the challenges of precision, efficiency, and innovation. As companies strive to meet the ever-increasing demands for high-quality aluminum extrusion products, manufacturers encounter hurdles in maintaining inventory while ensuring quality standards. With the rising competition, it has become imperative for organizations to stay ahead with cutting-edge techniques and machinery.

Precision and Innovation in CNC Machining

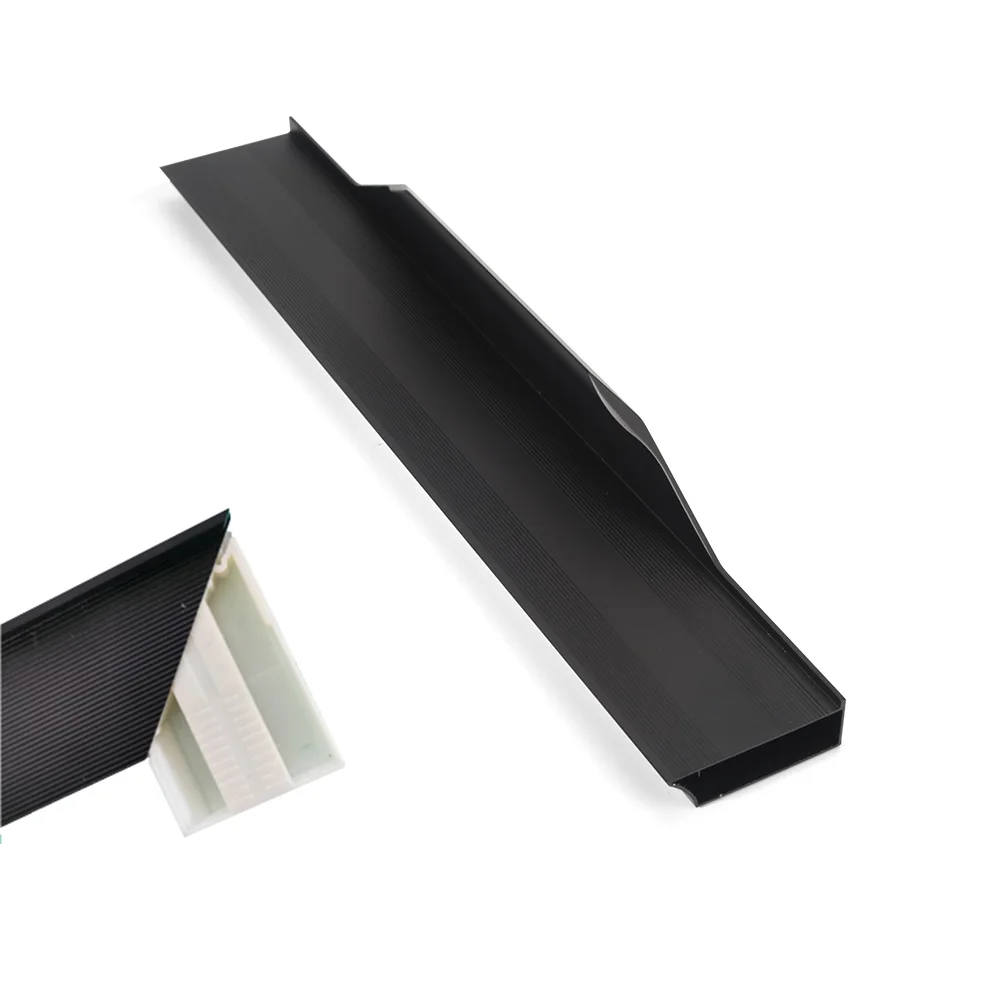

Enter the epitome of innovation: the state-of-the-art CNC machining and aluminum extrusion suite. This advanced machinery is transforming the landscape of metal manufacturing, particularly in locations like the renowned Foshan aluminum factory. The highly advanced CNC Center stands out for its unparalleled accuracy in crafting complex components. Its sleek design coupled with an intuitive control panel ensures operators can efficiently produce high-volume products without compromising on precision. This robust build promises to keep quality at the forefront while delivering impeccable craftsmanship.

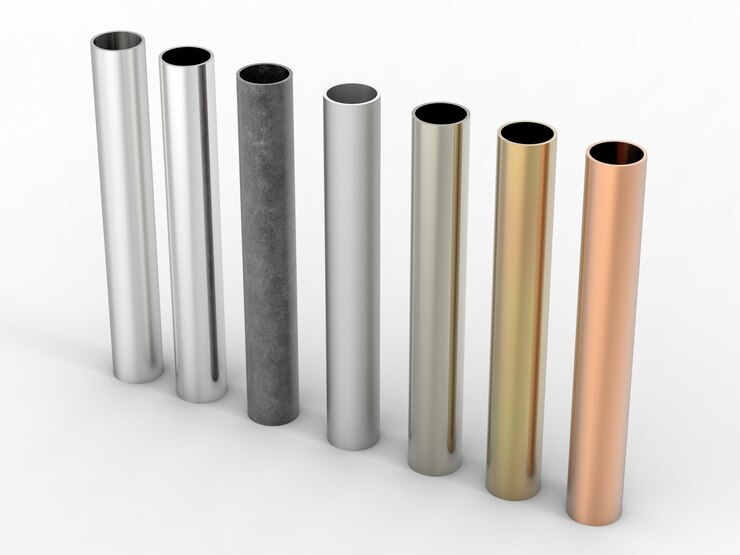

The 10,000-Ton Aluminum Extrusion Machine: Revolutionizing Production

For aluminum extrusion manufacturers looking to overcome traditional production hurdles, the introduction of the Horizontal CNC Center and the formidable 10,000-Ton Aluminum Extrusion Machine is nothing short of a game changer. This powerhouse of metal shaping is designed to tackle demanding extrusion applications with ultimate force, producing intricate aluminum profiles at record speed. Its vibrant yellow and blue design encapsulates its industrial strength and authenticity. By handling long parts with exceptional geometry and finish, the Horizontal CNC Center further enhances customization and optimization possibilities, turning raw materials into intricate masterpieces swiftly.

Redefining Manufacturing Efficiency

This suite of advanced machinery has redefined efficiency in aluminum production. The integration of cutting-edge technology with impeccable craftsmanship allows manufacturers to push the limits of innovation, ensuring minimal defects and superior product quality. As companies continue to adopt these marvels in metal manufacturing, they are not only enhancing their production capabilities but also setting new benchmarks in the industry.

In conclusion, aluminum extrusion manufacturers have the opportunity to significantly improve their production processes through advanced machinery and innovative techniques. As the industry continues to evolve, embracing such technological advancements will be key to staying competitive and delivering high-quality aluminum products.