Uncover the crucial elements driving the expense of aluminum extrusion. Learn how to refine your ventures for efficiency and thrift. From resource picks and crafting techniques to layout approaches and mass production advantages, this handbook explains all you need to understand. Whether you’re in building, automotive, or other areas, harness the power of aluminum extrusion with seasoned wisdom and pointers!

Factors Affecting the Expense of Aluminum Extrusion

When assessing the price of aluminum extrusion, several pivotal aspects emerge. Grasping these factors can aid you in making wise choices about using this adaptable material in your undertakings.

Material Expenses

The price of raw supplies forms a hefty chunk of aluminum extrusion costs. Aluminum alloy resources, like 6061 and 6063 T5 T6, are frequently used to create extrusion forms. These resources typically hold 97% aluminum content, boosting their toughness and capability. Their cost can shift based on market cravings, stock levels, and global financial trends. Also, the thickness of the aluminum form, spanning 0.9mm to 2.5mm, alters resource expenses.

Crafting Techniques

The production techniques linked to aluminum extrusion also add to its total price. Cutting-edge anodizing and powder coating methods are applied to ensure each piece not only meets but outshines industry norms for resilience, allure, and effectiveness. These techniques need specialized tools and adept workers, which can hike crafting costs. Plus, the intricacy of the extrusion layout and any extra finishing touches can further sway expenses.

Labor and Running Costs

Labor and running costs are vital pieces of the full expense of aluminum extrusion. Skilled staff are essential to handle machinery, oversee crafting streams, and carry out quality reviews. Running costs cover facility care, utilities, and administrative outlays tied to operating a production site. Together, these elements shape the pricing model of aluminum extrusion services.

Cost-Cutting Approaches in Aluminum Extrusion

To lessen the expenses tied to aluminum extrusion, several tactics can be used adeptly.

Design Optimization

Refining the layout of your aluminum extrusions can bring notable savings. By streamlining patterns and trimming needless intricacy, you can cut resource use and ease crafting steps. Moreover, partnering with veteran engineers during the planning phase can spot potential efficiencies. This preserves quality and usefulness while slashing costs.

Volume Production Benefits

Making aluminum extrusions in bigger batches often yields savings through economies of scale, dropping per-unit prices. With a minimum order quantity (MOQ) of 500 kgs per design at Xihui Aluminum, larger batches distribute fixed costs across more pieces. This lowers the overall price per item. This method suits large ventures where steady quality and capability are key.

Uses of Aluminum Extrusion Across Fields

Aluminum extrusions serve varied fields due to their flexibility and favorable traits.

Automotive Field

In the automotive realm, aluminum extrusions are valued for their light yet robust nature. They help trim vehicle weight while keeping structural firmness—a crucial element for boosting fuel thrift and performance benchmarks.

Building and Design

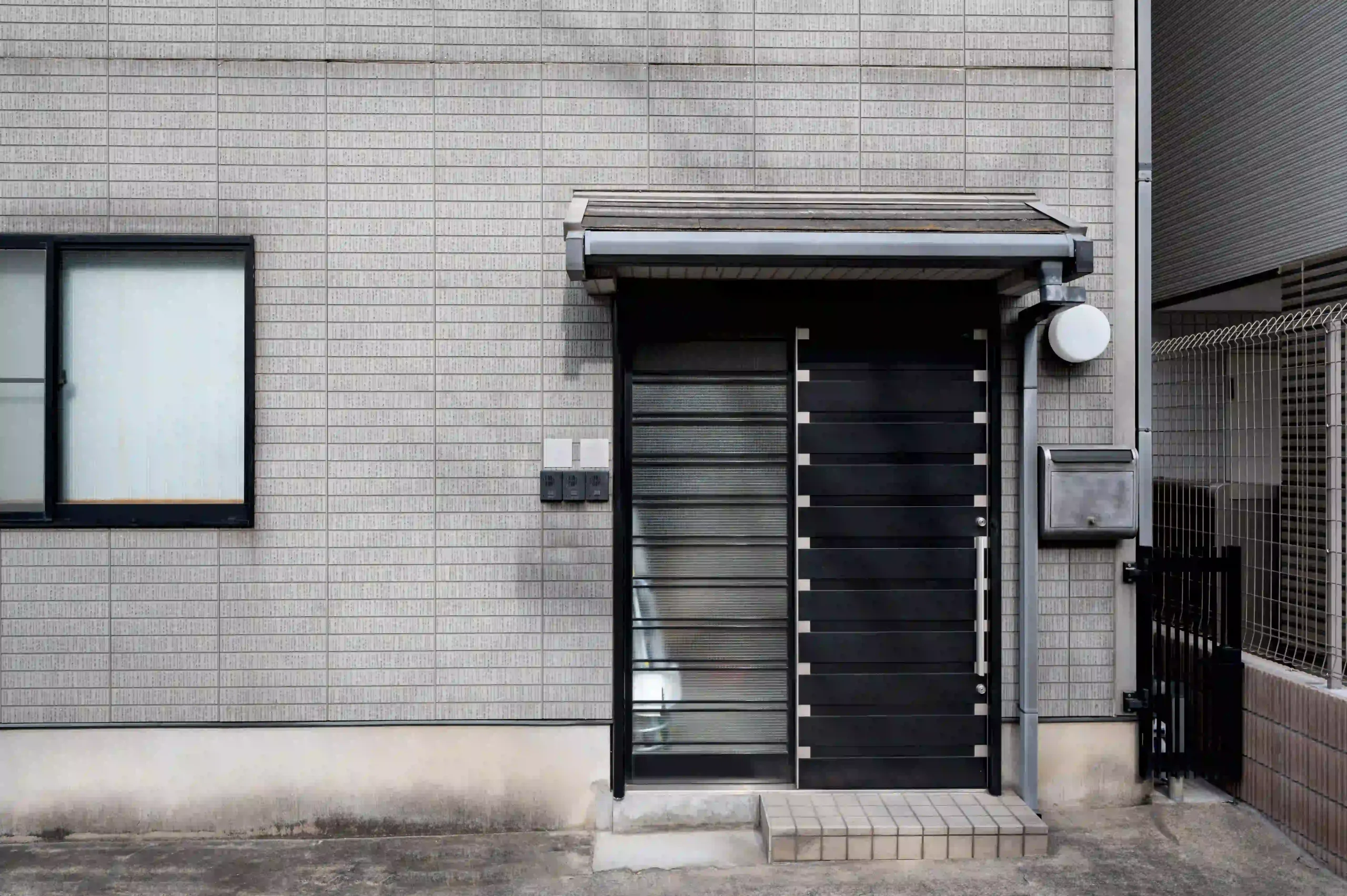

Aluminum extrusions are essential in building and design, providing sturdy answers for windows, doors, curtain walls, and other framework parts. Mostly used for aluminum alloy sliding windows and doors, these forms offer both visual charm and practical perks like rust resistance and simple setup.

By mastering these cost-affecting factors and delving into refinement tactics within fields like automotive or building, you can wield aluminum extrusion cleverly while keeping expenses manageable across diverse undertakings.

XiHui Aluminium: A Trustworthy Ally for Your Needs

When sourcing top-notch aluminum extrusion goods, XiHui Aluminium shines as a dependable ally. Their pledge to excellence and client delight is clear in their broad array of services and products crafted to meet varied field demands.

Company Snapshot

XiHui Aluminium runs a high-tech production hub fitted with advanced anodizing and powder coating systems. This ensures each piece meets and exceeds industry norms for resilience, allure, and effectiveness. Their use of A-grade aluminum resources highlights their devotion to excellence, delivering sturdy and eco-conscious solutions for building demands. With a focus on innovation and thrift, XiHui Aluminium offers a wide range of services, including ODM & OEM answers. These cater to the unique needs of architects, builders, and contractors.

Product Range

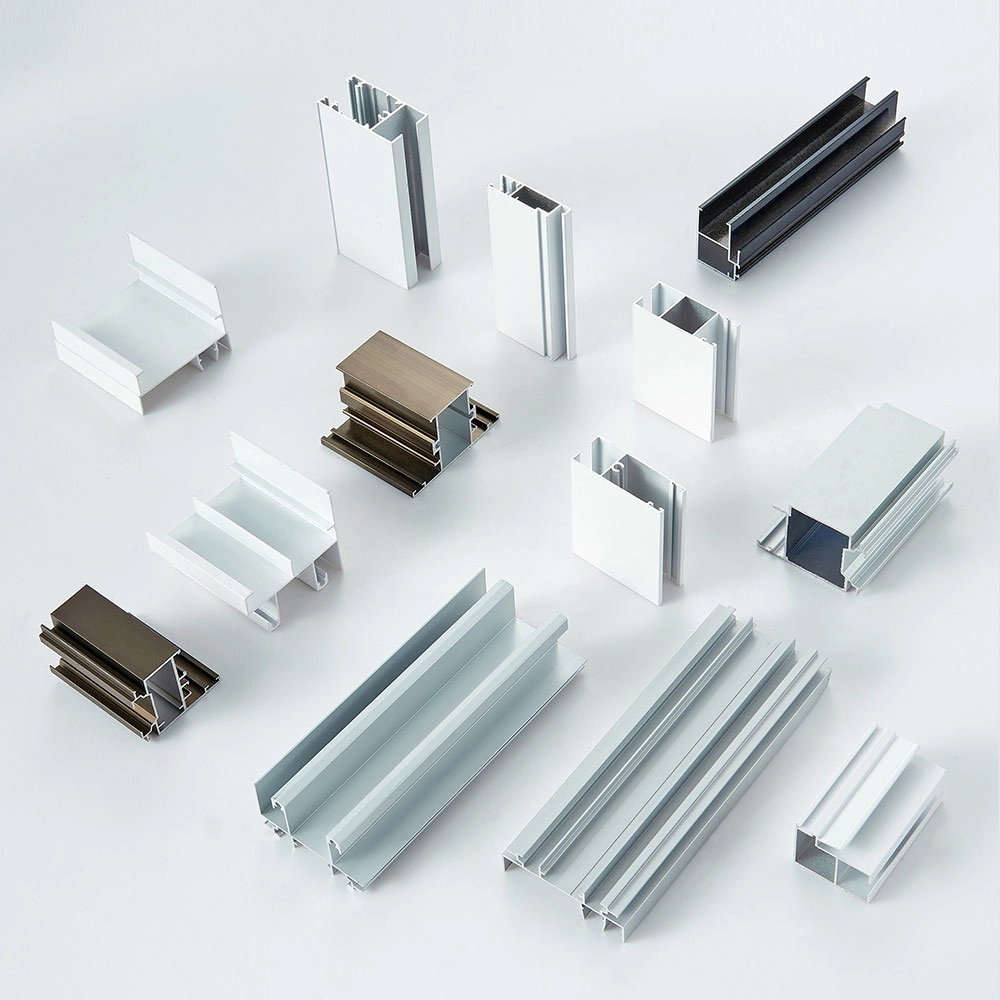

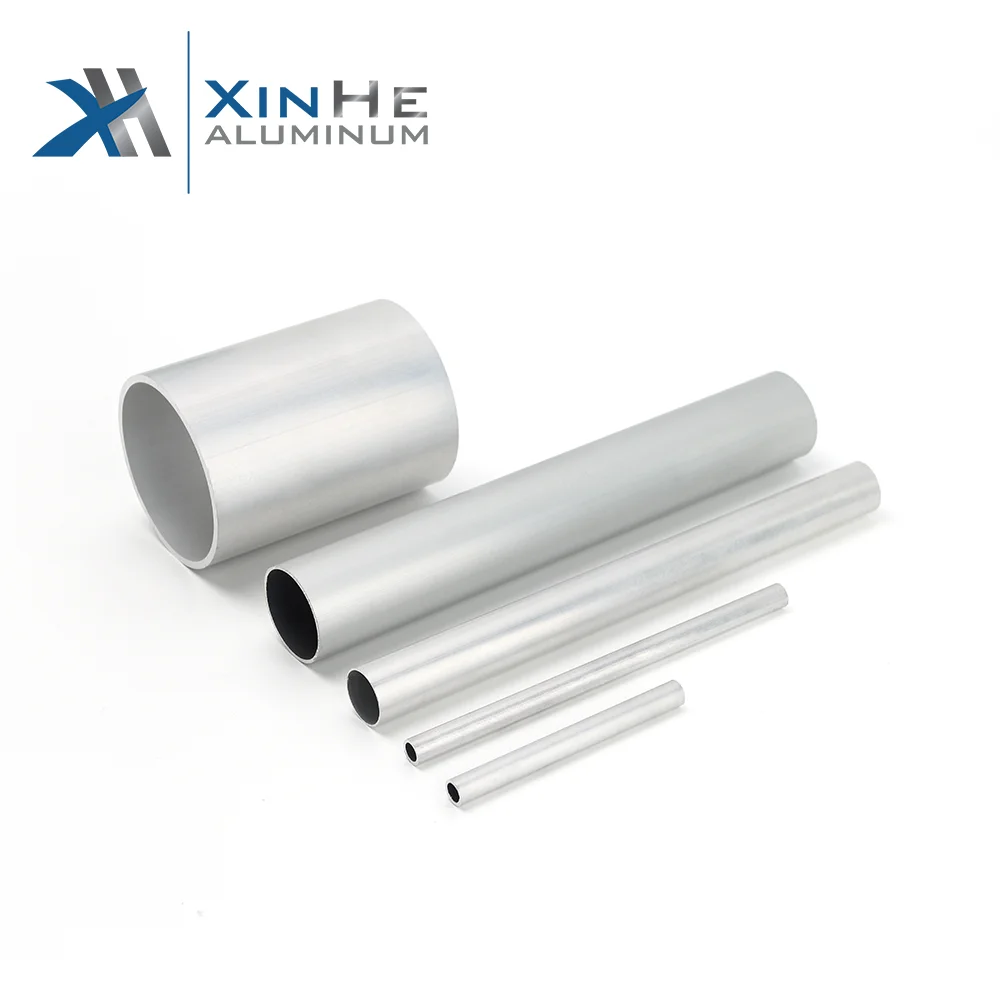

XiHui Aluminium’s product range is built to suit various uses across fields. Their broad lineup includes architectural forms mainly for aluminum alloy sliding windows, sliding doors, casement doors, windows, and glass curtain walls. They also supply structural forms like square tubes and round tubes, fitting for diverse building and decor purposes. For niche uses, they provide cabinet forms tailored to the custom demands of kitchens and storage spots.

What’s more, their vast array of accessories for aluminum alloy doors, windows, and curtain walls ensures smooth blending into any venture. This includes corner joint sets, handle sets, door lock sets, hinge sets, latch sets, sliding roller sets, and silicone sealant sets. With thickness choices from 0.9mm to 2.5mm and finishes like polished anodized silver and assorted powder coatings, XiHui Aluminium’s goods are both useful and chic.

Conclusion

The expense of aluminum extrusion hinges on many factors, including resource costs, crafting techniques, labor outlays, layout refinement chances, mass production gains, and the specific uses within fields like automotive or building. By teaming with reputable suppliers like XiHui Aluminium, who prioritize excellence via advanced crafting methods, you can adeptly manage expenses. This lets you tap into the flexibility of aluminum extrusions across varied undertakings.

FAQs about Aluminum Extrusion Costs

What Elements Most Affect the Expense of Aluminum Extrusion?

Several crucial elements shape the expense of aluminum extrusion:

- Resource Costs: The alloy type used greatly affects costs. Alloys like 6061 and 6063 T5 T6, with 97% aluminum content, enhance toughness.

- Crafting Techniques: Methods like cutting-edge anodizing and powder coating need specialized tools, hiking expenses.

- Labor & Running Costs: Adept staff handle machinery, while running costs cover care. Both mold the pricing model.

How Does Aluminum Extrusion Compare Cost-Wise to Other Resources?

Aluminum extrusion boasts several edges over other resources due to its light yet sturdy traits, making it perfect for fields like automotive where weight cuts matter without sacrificing firmness. Though initial resource costs may differ by alloy pick, the lasting perks—like rust resistance and easy setup—make it a thrifty choice compared to options like steel or plastic blends.

Can Layout Changes Cut Aluminum Extrusion Costs?

Yes! Layout refinement plays a hefty role in slashing expenses tied to aluminum extrusions:

- Streamlining Patterns: By trimming needless intricacy during the planning phase, resource use drops, directly lowering crafting costs.

- Joint Engineering: Teaming with seasoned engineers spots efficiencies that keep quality and usefulness while curbing overall outlays.

By mastering these affecting factors and delving into tactics within specific uses, you’ll find ways to manage expenses shrewdly. This lets you harness the adaptable traits of top-notch extrusions from trusted allies like XiHui Aluminium!