CNC systems are changing how aluminum alloys are customized in sectors. They offer exact and adaptable answers. These answers meet specific requirements. They also enhance functionality and look. Gain understanding into how progress in CNC systems and smart design are transforming aluminum alloy production.

How Does CNC Processing Revolutionize Aluminum Alloy Customization?

The evolving production sector has shifted. CNC machining systems now make a significant impact. They customize aluminum alloys efficiently and productively. Combining techniques with CNC operations enables production of customized alloys. These alloys meet exact requirements and enhance functionality and visual appeal.

The Role of CNC Processing in Modern Production

CNC operations automate tasks in production. They ensure exactness and quality. They’re crucial for shaping aluminum alloys to sector standards. CNC transforms alloy blends for diverse industrial purposes.

Advantages of Customization in Aluminum Alloys

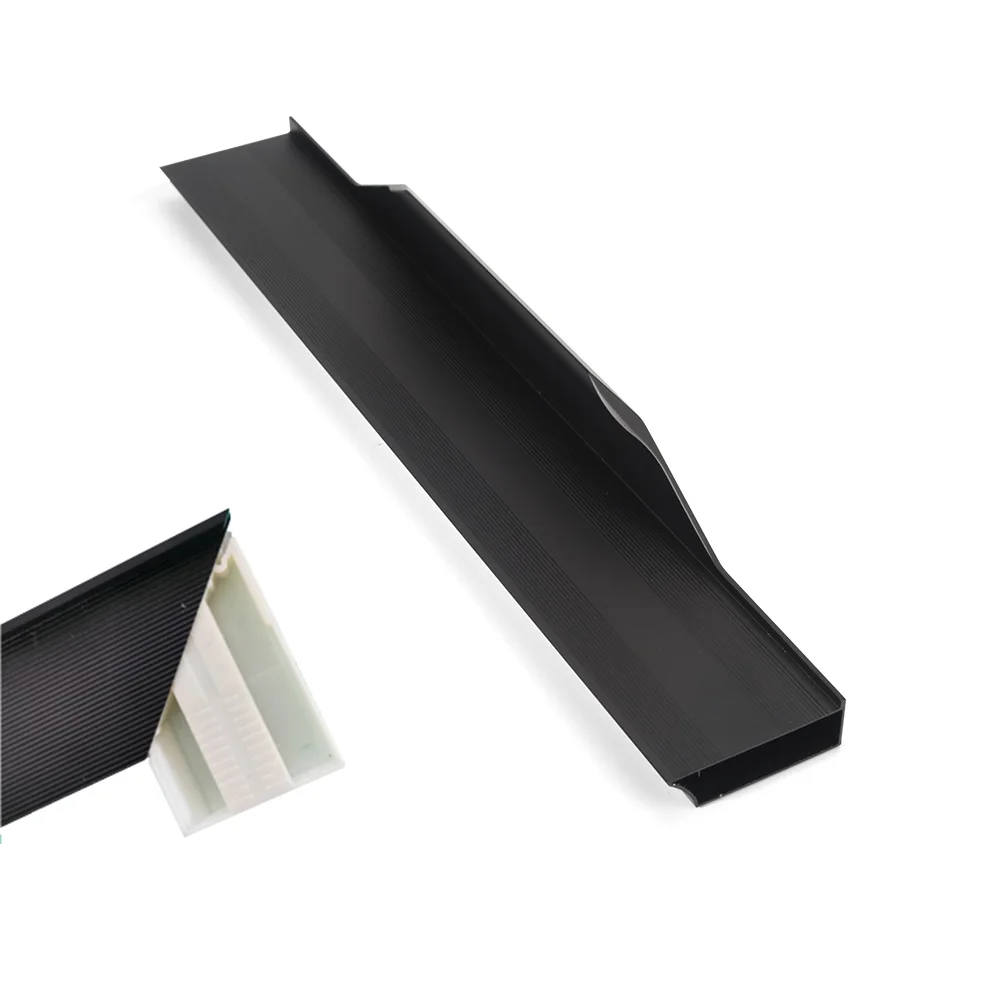

Customizing aluminum alloys benefits various sectors. It enhances functionality and longevity. These alloys offer great strength-to-weight ratios. They resist corrosion and transfer heat well. Products range from 0.9mm to 2.5mm thick. Finishes include polished anodized silver and powder coatings. This customization meets architects’, builders’, and contractors’ requirements. It fulfills practical and artistic demands.

Innovations in CNC Systems

CNC systems progress with advanced software. This enables exact customization of aluminum alloys. The software allows intricate designs with great accuracy. Our ODM & OEM services focus on adaptability and offer customer-focused strategies. These provide personalized answers from design to shipment.

What Are the Advantages of Smart Development in Aluminum Alloys?

Progress in aluminum alloy systems results in better production efficiency. It also improves eco-friendliness. Smart operations use data-driven strategies. These reduce environmental harm while enhancing production.

Enhanced Exactness and Efficiency

Smart progress boosts accuracy and productivity. It uses data analysis and machine learning tools. These tools enhance production operations efficiently. It reduces waste. It also improves resource management. This leads to production without losing quality or exactness. It allows higher output while maintaining great quality standards.

Environmental Impact and Eco-friendliness

Eco-friendliness is a priority in modern production. Smart development protects the environment. It minimizes energy use and waste in production. This method aids global efforts to cut carbon emissions, making quality output stays intact.

Cost-Effectiveness and Resource Management

Progress in aluminum alloys optimizes operations. Mechanization and resource management cut costs and make quality remains consistent. Effective material use lowers expenses across the supply chain. Thus, CNC systems and smart innovation enable customized answers for sector-specific requirements.

How Can Sectors Benefit from Customized Aluminum Alloys?

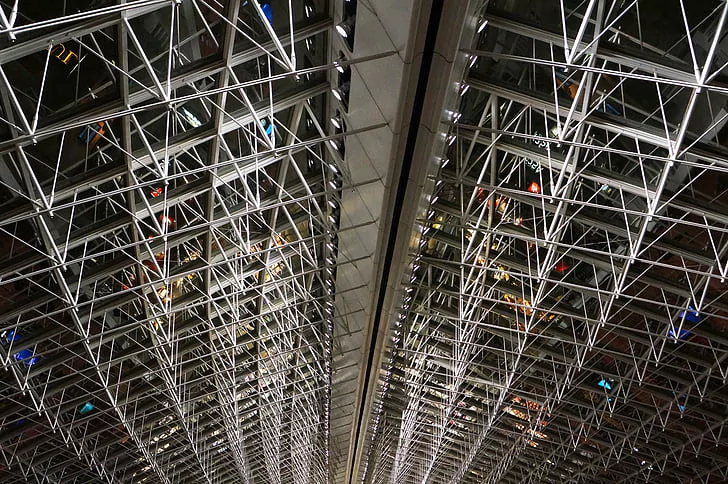

Customizing aluminum alloys with CNC operations offers advantages across sectors. Adjusting materials to meet requirements boosts functionality and efficiency. From aviation to consumer electronics, the benefits reach far.

Aerospace and Automotive Applications

Aerospace and automotive sectors need lightweight materials. These must maintain strength and safety. Customized aluminum alloys meet this demand. Meanwhile, they improve functionality and safety measures.

Lightweight Components

Customized alloys create vital parts. These suit aerospace and automotive uses. The reduced weight increases fuel efficiency. It also lowers emissions. This aligns with eco-friendliness goals, ensuring the strength in tough conditions.

Improved Functionality and Safety

Customized alloys help improve functionality. They allow exact tuning of traits like strength, longevity, and corrosion resistance. This tailored method ensures parts work optimally. It also meets strict safety rules. Adaptable formulations encourage creative design, which increases overall vehicle efficiency.

Consumer Electronics and Household Appliances

Customized aluminum alloys shine in electronics and appliances. They enable appealing and functional products.

Longevity and Aesthetic Appeal

Specialized alloys offer strength and longevity. They endure tough conditions. Coatings create specific visual effects. These suit consumer goods where look and functionality matter. Products range from 0.9mm to 2.5mm thick. Finishes include anodized silver and powder coatings. They meet practical and style preferences.

Heat Transfer Advancements

Efficient heat management is vital in gadgets. Customized alloys with better heat transfer are crucial. They disperse heat effectively. This ensures devices operate within safe temperature ranges. This trait excels in cutting-edge electronics where heat is a priority.

What Are the Obstacles of CNC Processing of Aluminum Alloys?

CNC operations for aluminum alloys have many advantages. However, they also present obstacles. These must be tackled to fully utilize their possibility. Knowing these obstacles helps you plan countermeasures.

Technical Constraints and Answers

Technical constraints in CNC operations may stem from machine or tooling limits. Yet, with ongoing system progress, answers exist. Investing in cutting-edge machines with improved capabilities upgrades production. It also increases exactness.

Material Selection and Compatibility Issues

Choosing the right material is key to CNC operations’ success. Material compatibility is vital to avoid corrosion or component failure. Carefully selecting alloy compositions based on application needs helps avoid incompatibility risks.

Future Trends and Chances

Future trends in CNC operations hold great possibility for innovation in customizing aluminum alloys. Combining with smart systems increases mechanization potential. Advanced software solutions offer new design freedom. Staying updated on these advances positions you to capitalize on future systems. These drive success in this cutting-edge sector.

Overcome current obstacles. Seize upcoming chances. This way, you can achieve new success levels. Smart development through CNC operations enables this. It drives constant growth in sectors relying on customized alloys.

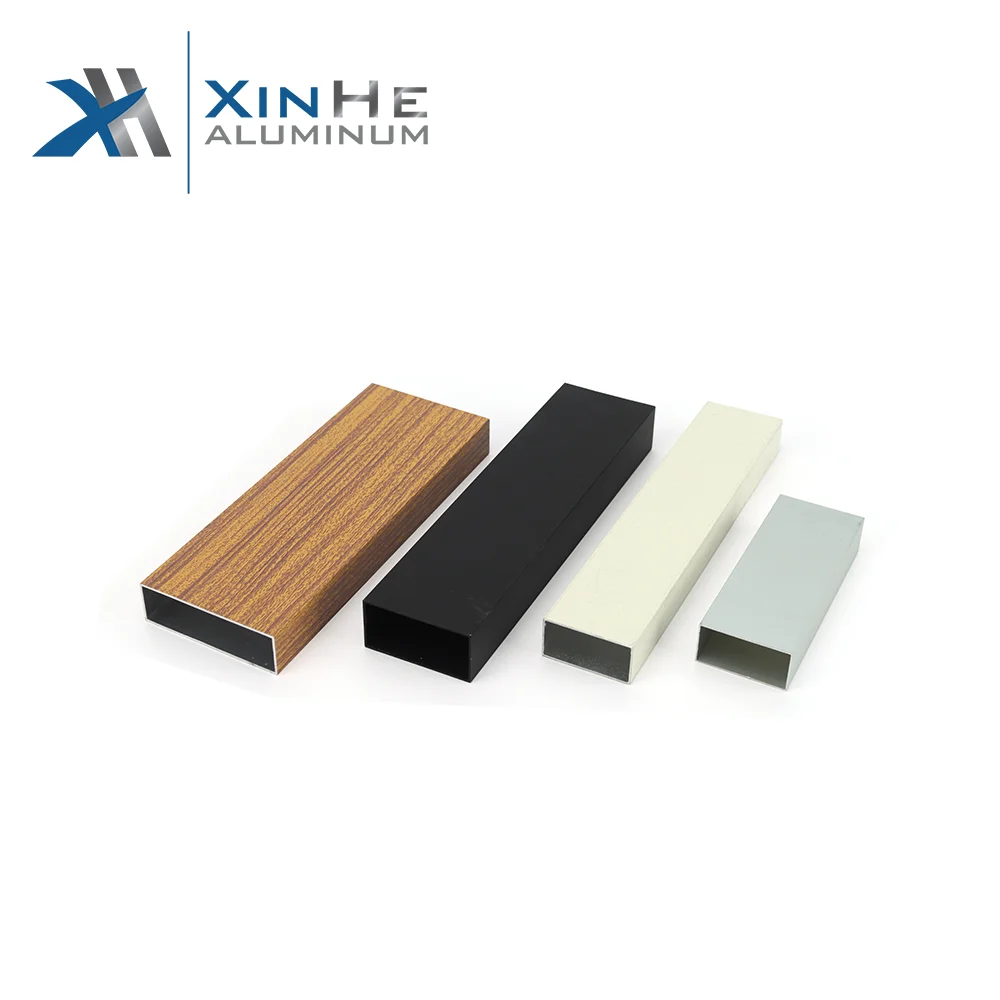

Why Choose XiHui Aluminium Co., Ltd as Your Supplier?

Choosing a supplier affects project success, XiHui Aluminum stands out for quality and service. They offer premium, durable products. They optimize operations to cut costs. Cutting-edge CNC machining increases productivity. It also reduces waste. Effective material use supports eco-friendliness. XiHui offers cost-effective products. Their ODM & OEM services are all-inclusive. They provide customized answers in design, production, packaging, and transport. Selecting XiHui, they will ensure premium, cost-efficient alloys to meet specific requirements.

FAQs

Q: Can smart CNC processing reduce production costs?

A: Yes, it minimizes waste through mechanization. It also cuts labor costs.

Q: What is the long-term benefit of implementing this system?

A: It increases productivity and reduces costs. It future-proofs production for changing requirements.

Q: Why use aluminum alloys with CNC processing?

A: They’re lightweight and strong and resist corrosion, which are ideal for exact machining.