In the world of manufacturing that is constantly moving at a fast pace, CNC prototyping has become a game changer for companies looking to produce items quickly and with precision. This method allows for the creation of prototypes, speedier delivery times, and guarantees high-quality results. Find out how CNC prototyping can address manufacturing requirements and transform your production procedures.

What is CNC Prototyping and How Does it Address Urgent Manufacturing Requirements?

CNC prototyping revolutionizes manufacturing, aiding in meeting production deadlines. Uses CNC machines can quickly craft prototypes, allowing design experimentation before full production and ensure products meet quality standards and consumer preferences efficiently.

The Basics of CNC Prototyping

To truly grasp the significance of CNC prototyping, one must have an understanding of its basic principles and how it effectively meets critical manufacturing demands.

Definition and Core Principles

Automating machining tools through a computer is what CNC prototyping is about! Its main goals are accuracy and efficiency in producing prototypes quickly using set software instructions for intricate tasks.

Key Components and Technologies Involved

The CNC machine plays a role in the manufacturing process and comes in different sizes and capabilities depending on the specific job requirements. The use of CAD (Computer Aided Design ) software for creating designs and CAM (Computer Aided Manufacturing ) software for mapping out the production process are technologies that collaborate to guarantee precise and effective development of prototypes.

Addressing Urgent Manufacturing Needs

In the dynamic market environment, it is essential to meet pressing manufacturing demands promptly to remain competitive. CNC prototyping serves as a factor in achieving this goal.

Speed and Efficiency in Production

CNC machines work quickly to help with fast production cycles which is important when facing tight deadlines or sudden high demand spikes in the manufacturing industry, shortening the time to create prototypes enables the swift transition from design to testing phases for manufacturers.

Flexibility in Design and Customization

Utilizing CNC prototyping provides versatility in design and personalization options for your projects or products. Whether you require modifications or completely new concepts developed, CNC technology allows for seamless adjustments without causing major disruptions to your operations. This flexibility guarantees that your merchandise stays current and in line with the market demands.

How Does CNC Prototyping Enhance Rapid Delivery?

One of the benefits of CNC prototyping is the efficient delivery of products enabled by incorporating cutting-edge technology.

The Role of Technology in Speedy Production

The speedy production abilities of CNC prototyping rely heavily upon the progress in technology.

Advanced Machinery and Software Integration

Today, CNC machines come with hardware that effortlessly interacts with state-of-the-art software systems. This seamless integration enables the execution of operations with little human involvement, resulting in a notable acceleration of production schedules.

Automation and Its Impact on Turnaround Time

The use of automation lessens the need for work and speeds up the production process even more efficiently than before. With automated systems in place, once a design is complete, it can be swiftly forwarded for production without any delays resulting in quicker delivery of final products.

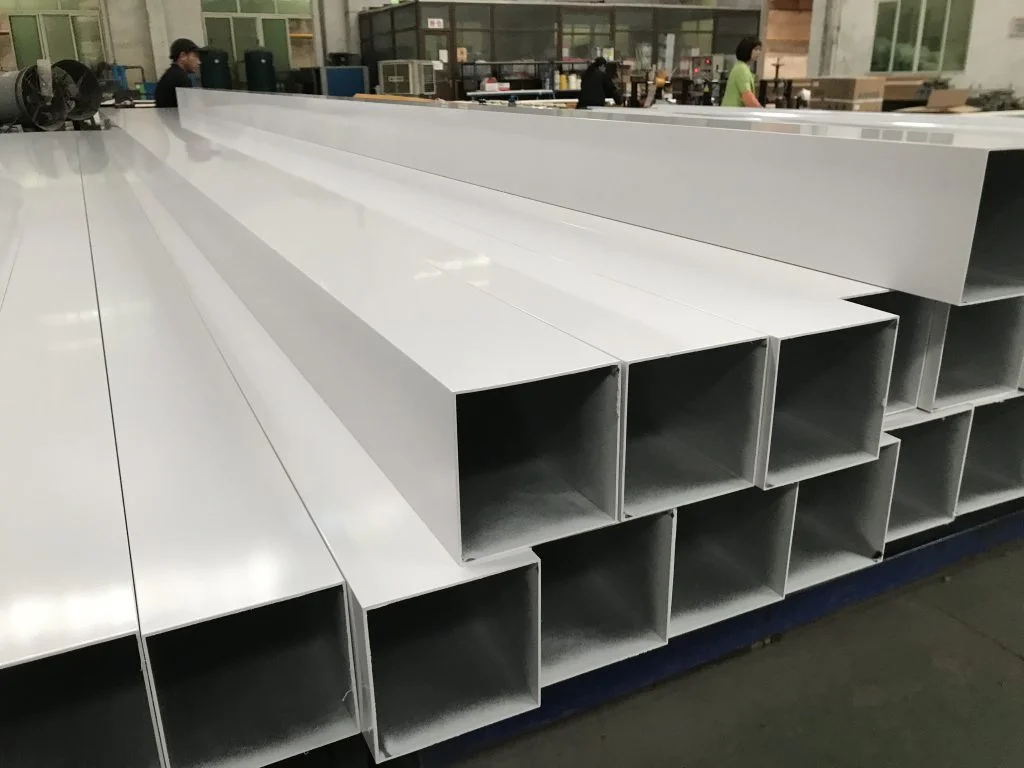

Case of Aluminum Alloy Enclosure CNC Machining with 3-Day Delivery

An excellent illustration of service is the quick turnaround for CNC machining on , which guarantees delivery within just three days.

Process Overview

The procedure includes utilizing custom CNC machines designed for aluminum alloy materials specifically. These machines are accurate. Mold casings according to digital blueprints to guarantee top-notch results quickly.

Benefits of Quick Delivery for Manufacturers

Speedy delivery provides advantages such as shorter waiting times for customers and improved satisfaction levels along with a stronger position in the market competition for businesses.

Why Choose CNC Prototyping for Aluminum Alloy Enclosures?

Opting for CNC prototyping of traditional techniques comes with clear benefits, especially in the case of aluminum alloy casings.

Precision and Accuracy in Manufacturing

The exactness provided by CNC machines guarantees that every casing meets requirements consistently. This precision helps in minimizing mistakes and decreasing wastage which leads to more effective production procedures.

Cost-Effectiveness and Resource Management

Optimizing the use of materials and cutting down on labor expenses with automation makes CNC prototyping a budget option. Managing resources efficiently leads to savings that can benefit consumers or be put back into driving innovation.

Quality Assurance Processes

In CNC thorough quality, checks are conducted to confirm that every product meets the design requirements before it is shipped from the production facility. This practice guarantees performance and reliability for all manufactured units.

Compliance with Regulatory Requirements

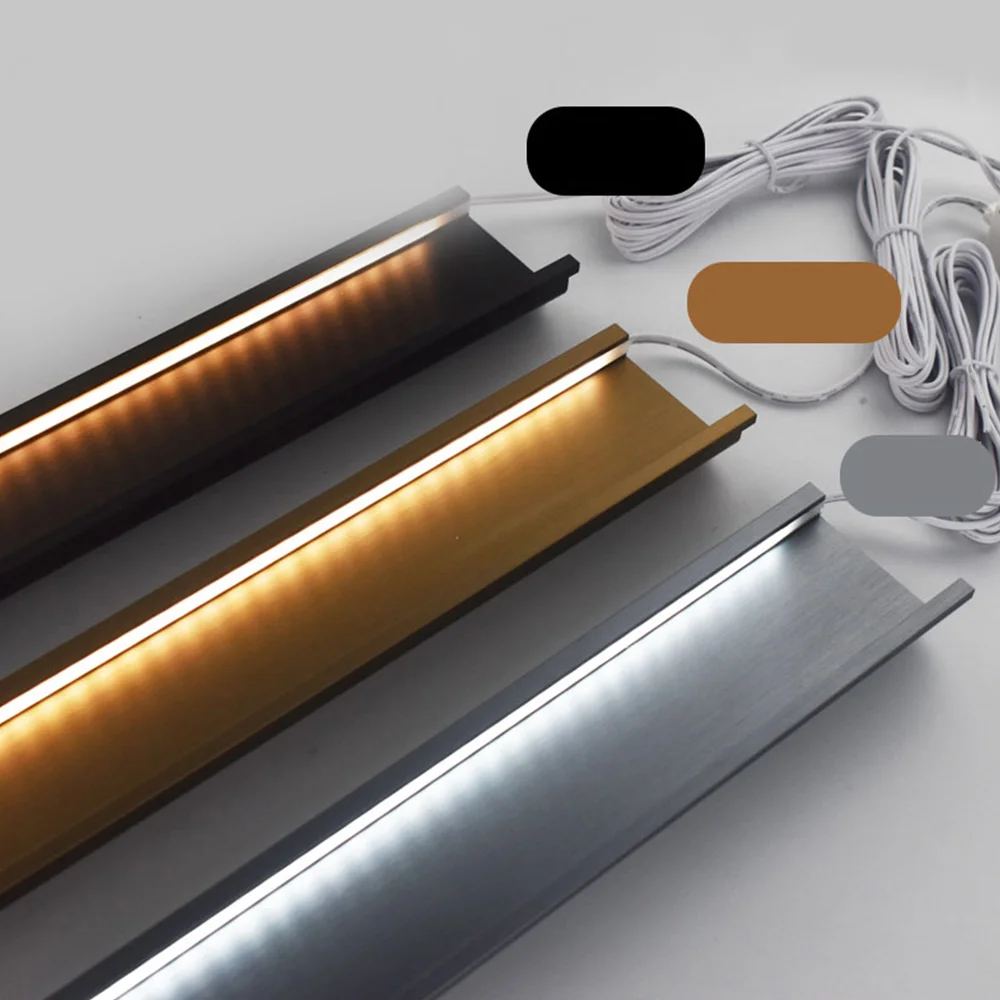

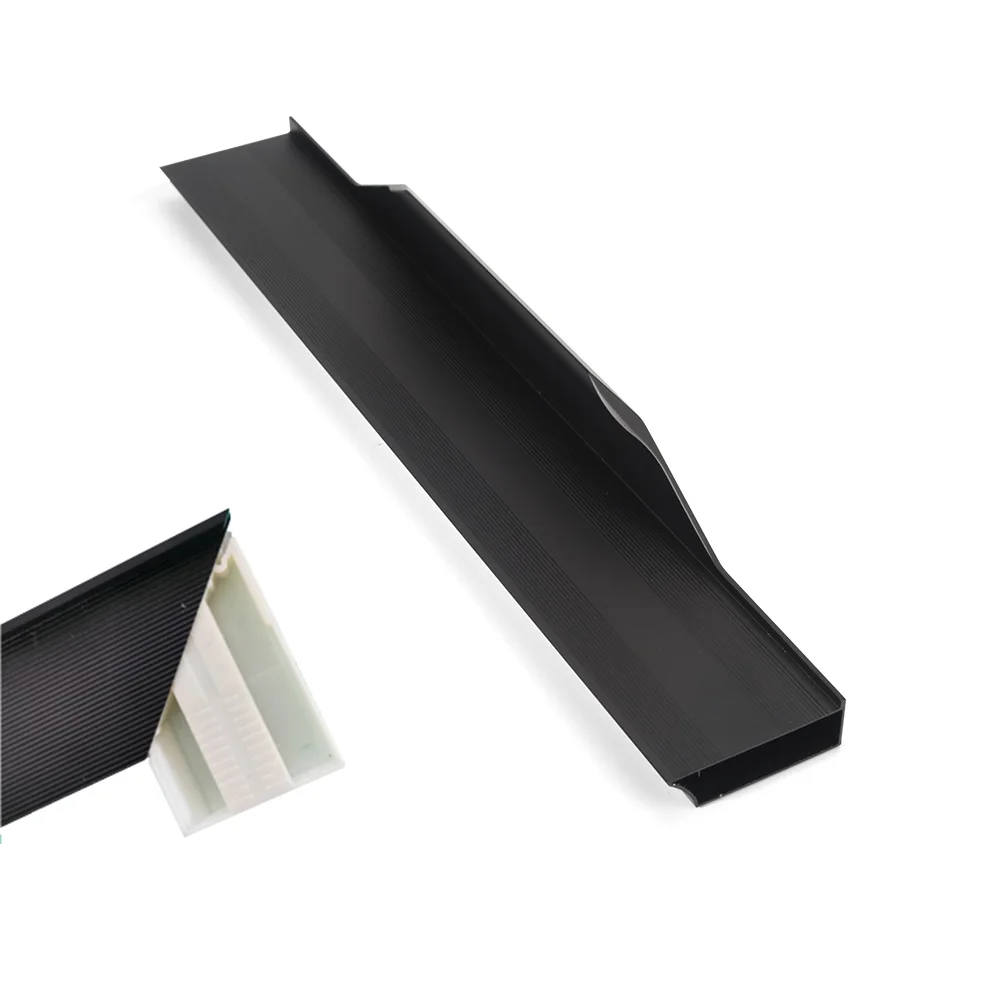

Manufacturers in industry sectors need to follow specific regulations as per their sector requirements, such as the ALUMINUM PROFILES CAMEROON MARKETs SLIDING & CASEMENT SERIES & SHOPFRONT DOOR APPLICATION SERIES which illustrates the importance of precise CNC machining for meeting strict guidelines effectively.

How is XiHui Aluminium Co., Ltd Contributing to the Industry?

XiHui Aluminium Company is recognized in the field for its proficiency in CNC technology. Offers high-quality aluminum profiles for various purposes. The company is well known for its approach and prioritizes ensuring quality and customer happiness to establish enduring relationships with its customers. By investing in cutting-edge CNC equipment, the company not only improves production efficiency but also contributes to the substantial growth of the industry. Explore how XiHui Aluminum’s dedication to excellence distinguishes them in the realm of aluminum profile production.

FAQs

Q: Why is CNC prototyping important?

A: CNC prototyping allows precise, high-quality prototypes which can be tested and optimized before mass production, saving time and cost..

Q: Can CNC prototyping handle complex designs?

A: Yes, CNC prototyping is ideally suited to create complex geometries and fine details, and hence is ideal for high-level designs.

Q: How costly is CNC prototyping?

A: Expenses are material, design complexity, and amount but CNC prototyping is cost-effective while making small series and high-precision parts.