When it comes to initiating a project, the choice of materials has to be economical, long-lasting and capable of reducing product weight as much as possible. Aluminum extrusions have become widely favored in sectors because of their flexibility and distinctive characteristics combination. Lets delve into the realm of aluminum extrusion and see why it could be a match, for your upcoming endeavor.

Knowing What Is Aluminum Extrusion

Aluminum extrusion is one of the most modern and important processes within industries today. It is a method of shaping the aluminum into a wide array of profiles, thus making it highly adaptable for innumerable applications. A better understanding of this process and its history will lead to an appreciation of its value and potential in your projects.

Definition and Process Overview

Aluminum extrusion is a process of forcing the aluminum alloy material through a die having a particular cross-sectional profile to give it the desired shape. The final long piece takes the desired shape through this process. It allows for complex cross-sections for various uses.

History of Aluminum Extrusion

The process of extrusion is believed to have existed since the 1700s. It was during the 1900s that aluminum extrusion became all the more important because of developments in material science and technology. The versatility and advantages of aluminum have made it a prized commodity in various industries.

Key Characteristics of Aluminum Extrusion

Aluminum that has been extruded possesses important qualities that make it a desirable option, for a wide array of uses improving its functionality and expanding its applicableness across different settings.

Strength and Durability

The strength-to-weight ratios of aluminium extrusions are very large due to alloying additives combined with specialized heat treatments for developing their mechanical properties in such a manner as to make them durable under severe conditions.

Lightweight Nature

Extruded aluminum boasts quality over heavier metals , such as steel, yet still retains the strength and integrity necessary in applications requiring lightweight efficiency without compromising durability.

Corrosion Resistance

Aluminum retains a natural oxide coating that enhances its capacity to handle corrosion very efficiently. This quality makes aluminum extrusions apt for both outdoor applications and those meant for very harsh environments.

Benefits of Aluminum Extrusion

Cost-effectiveness, design flexibility, and environmental benefits combine to make the option highly versatile and attractive for product designers and engineers. Most of the above-mentioned advantages have made the material a preferred one in most industries.

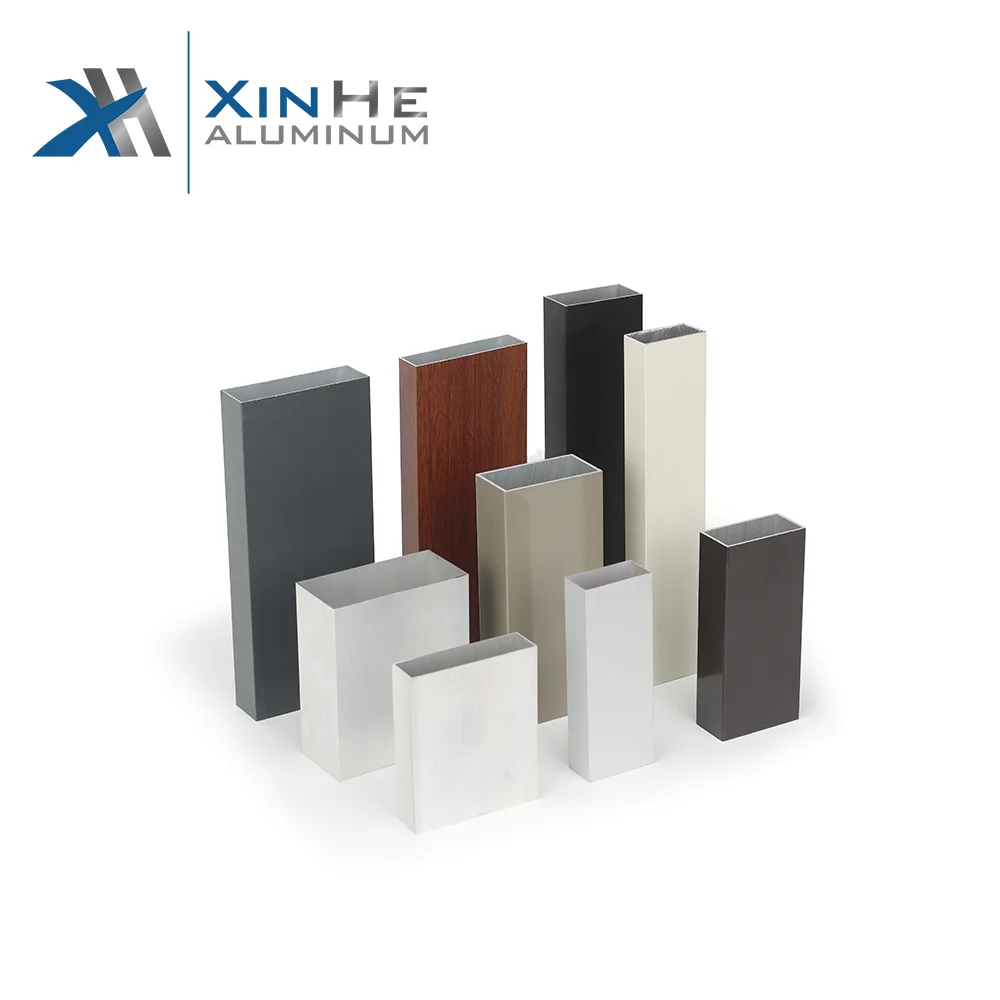

Customizable Shapes and Sizes

Aluminum extrusion is available in a range of design options that allow manufacturers to create custom shapes and sizes depending on specific project needs. This flexibility encourages innovation in designs and practical solutions across various industries.

Complex Cross-Sections

Extrusion opens the door to forms and shapes that hardly had an alternate approach in the range of conventional making, hence diversifying the frontiers of use in aluminum products by extrusion manufacture.

Material Efficiency

The process of extrusion is cost-effective by and large due to the lessening of wastage by applying only the specific quantity of material the profile requires- a technique which offers added financial benefits both at production and buying perspectives.

Reduced Production Costs

Creating shapes in an operation reduces the need for additional machining or assembly processes and leads to cost savings in production at Xihue Aluminum’s state-of-the-art manufacturing facility that ensures high-quality outcomes at an affordable price point.

Recyclability of Aluminum

Among metals, aluminum is highly recyclable without losing any of its properties. Indeed, for extrusion processes, recycled aluminum consumes less energy compared to material production from raw ore and, thus, is a greener alternative worth considering.

Energy Efficiency in Production

Xihui Aluminum employs energy in producing aluminum extrusions compared to other metal shaping techniques improving energy efficiency with their advanced anodizing and powder coating processes while ensuring top-notch product quality.

Applications of Aluminum Extrusion in Various Industries

Extruded aluminum is used in many industries because of its versatile properties. From automotive to construction and electronics, the applications of aluminum extrusion are huge. Understanding these uses can give you a better sense of its adaptability.

Automotive Industry Applications

The usage of aluminum extrusions in the automotive world makes for lightweight parts, hence enhancing fuel economy and performance. Vehicle cross members, subframes, trim, and accessories can be made from extruded aluminum to lower weight without losing strength. That is lightweighting and it helps the vehicles be more efficient.

Construction and Architecture Uses

Large consumers of aluminum extrusions are found in the construction and architecture industries. Many construction elements, from structural frameworks to aesthetic facades, include applications in an overwhelming majority of architectural components using aluminum. Because of its strong corrosion resistance, high strength-to-weight ratio, and design flexibility, aluminum is exceptionally option for several building applications.

Electronics and Consumer Goods

Aluminum extrusions also find very wide applications in the electronic and consumer goods industries. The high thermal and electrical conductivity of aluminum, along with the ease of its shaping, makes it a popular material for everything from heat sinks to durable casings.

Considerations When Choosing Aluminum Extrusion for Projects

These are some of the many factors that you need to look into when deciding on the material of aluminum extrusions for your project. This will ensure you get the correct materials and processes for the best results. The right material and processes will make sure your product meets all your requirements.

Material Selection Criteria

The selection of aluminum for your project should be based on the intended material use, environmental conditions, and performance requirements. Different aluminum alloys offer a wide range of strength, corrosion resistance, and other properties. Take into account the distinct qualities of aluminum and how they align with what your project demands.

Collaborating with Manufacturers

It’s very important to work closely with your aluminum extrusion manufacturer to ensure you get the right products. Not only does this ensure that your designs are optimized for the extrusion process, but it also ensures your products will meet your requirements. Communication is the key with your manufacturer.

Future Trends in Aluminum Extrusion Technology

The aluminum extrusion industry is dynamic and you should expect much more in innovative production techniques and applications. Being current will help you capitalize on the new opportunities.

Production Techniques Innovations

Advances in the manufacturing process drove modern aluminum extrusion technology to incorporate more automation and precision engineering in design studies while keeping production costs economical, therefore widening the fields of application for aluminum extrusions.

Emerging Markets and Applications

Aluminum extrusion is becoming increasingly popular in emerging markets for its versatility and effectiveness in industries such as renewable energy and transportation infrastructure due to its lightweight nature that suits eco-friendly solutions in these growing sectors well. Additionally, as companies emphasize sustainability now more than before the recyclability of aluminum offers additional advantages for the future.

When you incorporate these elements into your project planning process, it can enhance your utilization of aluminum extrusion technologies capabilities effectively. Efficiently achieve both functional and aesthetic goals while also being sustainable and eco-friendly by selecting the right alloys collaborating with experienced manufacturers, such as XiHui Aluminium Co., Ltd, and staying informed about industry advancements. With three decades of expertise, Foshan Xihui Aluminum Co. Ltd is an established producer of aluminum extrusion profiles, known for its focus on crafting slim profiles and a diverse product selection that includes Architectural profiles for doors, windows and curtain walls, Cabinet profiles for kitchen and storage solutions and Industrial profiles for various applications. Xihui operates 15 automated extrusion lines alongside 2 anodizing lines and 2 powder coating lines to manufacture an array of aluminum profiles in different sizes and shapes. Moreover, they specialize in ODM & OEM services, providing customized solutions covering design production packaging and logistics as well as offering various accessories and machinery for a smooth procurement experience.

FAQs

- Where are the uses of aluminum extrusions made?

Aluminum extrusions are utilized in building and automobile industries, electrical equipment and consumer goods production.

2. Why is it that the manufacture of aluminum extrusions costs less compared with other forms of manufacture?

The manufacturing process through an aluminum extrusion cuts down on wastage and dispenses with the use of secondary processes, therefore, it increases speed and decreases overall manufacturing costs.

- How does the process of aluminum extrusion support environmental conservation efforts?

Aluminum is easily recyclable. Using recycled aluminum helps energy usage and reduces the environmental footprint as well.