Exploring Aluminium tubing Schedules

Aluminum pipes are gaining popularity due to their durability, making them suitable for various industries. It’s important for professionals working with these materials to understand aluminum pipe schedules. Xihui Aluminium is a key player in this field, offering a range of high-quality aluminum products. Xihui focuses on manufacturing aluminum pipes and tubes that comply with industry standards such as ASTM and JIS. Xihui Aluminium provides a variety of products, including alloy bars and pipes, as well as customized solutions tailored to meet specific client needs in industries such as automotive and construction. This is due to their dedication to innovation and high-quality production methods.

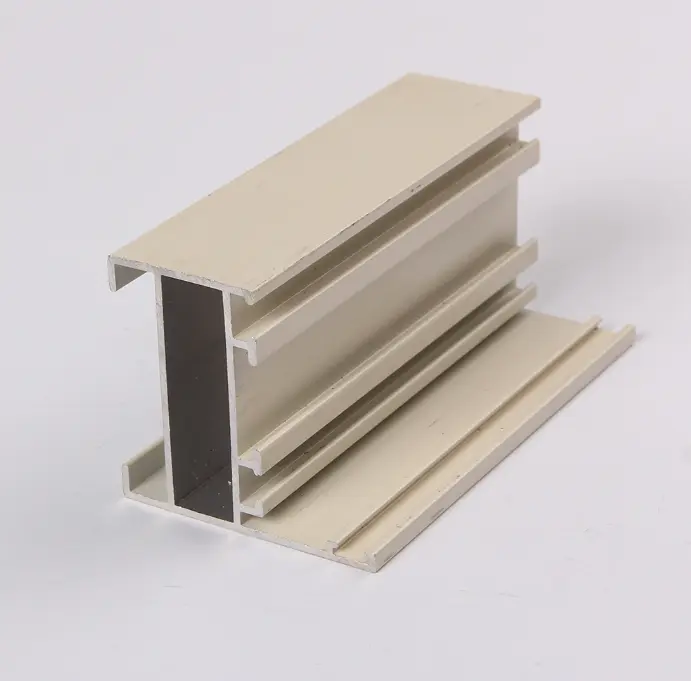

Different Types of Aluminum Tubing

Aluminum tubes are grouped into categories based on their characteristics such, as properties and alloy compositions which determine their specific uses in various industries or applications. The 1000 series is known for its ability to resist corrosion and is commonly employed in storing and transporting chemicals. The 2000 series stands out for its strength-to-weight ratio. Is favored in the aerospace and military sectors for building structures. The 3000 series is appreciated for its ease of shaping and fabrication. Is typically utilized in producing cans and household appliances. The 5000 series is known for its corrosion resistance, in marine settings where it excels. In settings, the 6000 series is well-liked for its combination of strength and ease of use. Industry professionals need to grasp these nuances when choosing the right aluminium tubing for use.

Aluminum Tubing Traits: What You Need to Know

When assessing aluminum pipes, for applications or projects; it’s important to consider key factors for making well-informed decisions. To begin with, the tensile strength of the tubing is a factor as it indicates the load that the tubing can withstand before failing. Similarly, understanding the yield strength is essential as it helps in determining the point at which the material will permanently deform. Additionally, other important attributes like corrosion resistance, lightweight design, and malleability play a role in decision making. Moreover, it’s worth noting that the surface finish of aluminum tubing can also impact its performance by affecting both strength and visual appeal. Those who are experienced in the field can effectively utilize the advantages of aluminum tubing by understanding these characteristics in depth.

Factors Influencing Tube Strength

The durability and efficiency of aluminum tubing are influenced by a range of factors, such as the makeup of the material itself and the specific alloy grades used in conjunction, with heat treatments and temper classifications.

Material Composition and Alloy Grades

The composition of materials plays a role, in defining the strength of aluminum tubes. Various alloy grades have compositions that impact their mechanical characteristics. For example, increased copper content in 2000 series alloys greatly enhances their strength could lower corrosion resistance. On the other hand, alloys featuring magnesium or manganese as the elements like those, in the 5000 series show excellent weldability and resistance to corrosion. Therefore, experts must carefully consider the use case when choosing the alloy that maintains the necessary strength while also preserving other important qualities.

Heat Treatability and Temper Classifications

The strength of aluminum tubing is significantly impacted by heat treatment methods as specific alloys can be reinforced through this process to improve their properties. Temper classification offers information, on the alloy heat treatment and working condition which helps predict the tubing performance, under stress. For instance, the T6 temper signifies a state of being solution heat treated and artificially aged resulting in increased strength and hardness levels. Professionals should grasp the significance of these categories. How they affect performance, in tasks that prioritize robustness and longevity. Xihui Aluminum items frequently undergo heat treatments to guarantee their performance, in challenging scenarios.

What is a Strong Schedule Tube?

To truly grasp the robust tube schedule entails an understanding of tube schedules and their impact, on strength levels. Tube schedules denote the thickness of tubing in relation, to its diameter measurement. In the case of aluminum tubing different schedules offer varying strengths by affecting the rigidity and load-bearing capabilities of the items. Typically the sturdiest tube schedules feature walls, which bolster their resistance to bending and shape alteration when in use.

Defining Tube Schedules

Tube schedules are a way of measuring the thickness of tubing walls, about the diameter of the tube itself. This system is important for maintaining consistency among various manufacturers and enables experts in the industry to evaluate the strength and suitability of tubing for their specific needs. Each schedule number corresponds to distinct measurements with higher numbers typically indicating thicker walls and higher pressure capabilities Knowing how to interpret these schedules is vital when choosing the appropriate aluminum tubing for applications, like building structures and pressure vessels.

Standard Schedule Ratings in the Industry

Rating standards, for aluminum tubing adhere to the guidelines set by organizations like ASTM and ASME. These standards categorize the tubes according to wall thickness about diameter. Common schedules such as Schedule 40 and Schedule 80 are used for classification. Schedule 40 is known for its walls. Is often preferred for nonstructural purposes such as drainage and ventilation. On the other hand, schedule 80 boasts walls that provide increased durability and strength making it a better choice, for structural applications or situations involving higher pressures.

Experts in the field must grasp the nuances between these ratings to make choices when buying materials for their projects or operations. Choosing the schedule guarantees that the aluminum tubing will meet the needs of the application without compromising safety or performance standards. Xihui Aluminium offers product documentation that explains the distinctions, among schedules and how they can be applied effectively to help customers make educated decisions.

Understanding the schedules of tubes and taking into account strength factors are key, in using aluminum tubing in performance-focused scenarios It emphasizes how crucial material characteristics and relevant standards are, in developing strong engineering solutions.

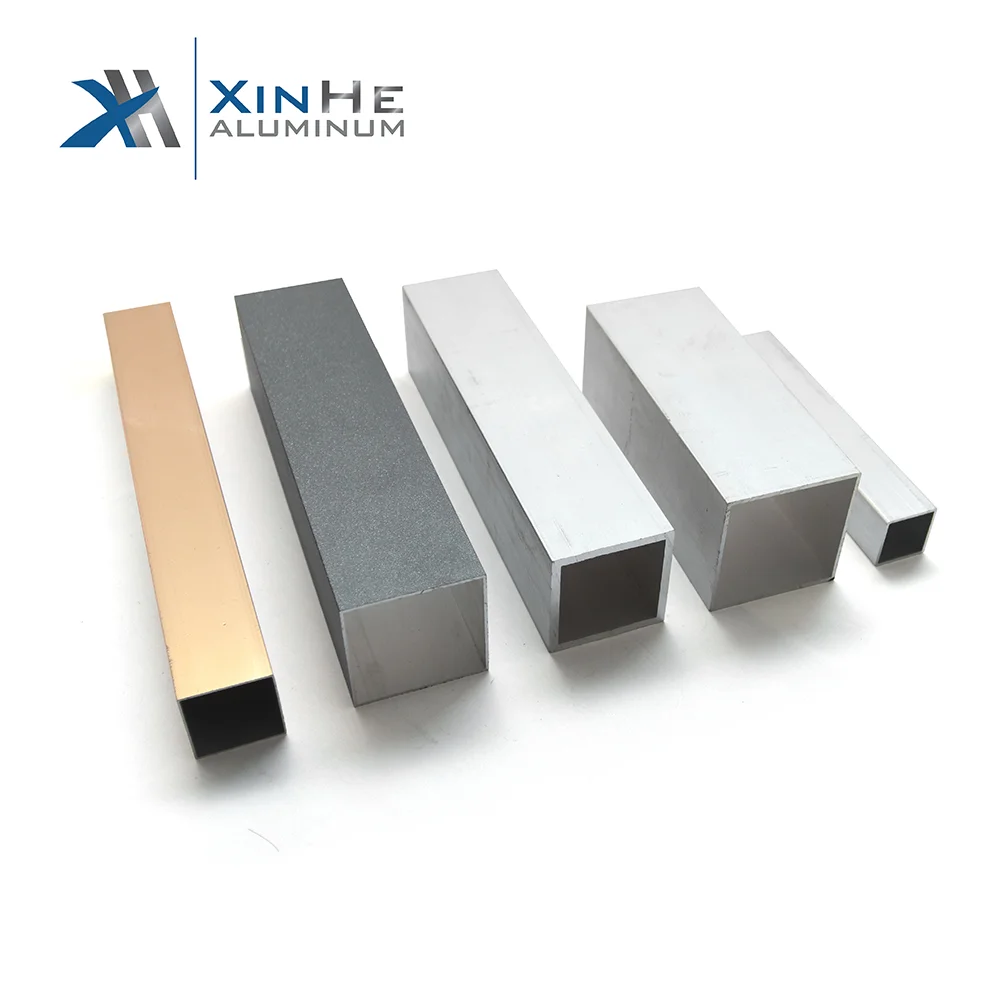

The Role of Xihui Aluminium in Providing High-Quality Tubing Solutions

In the industry, Xihui Aluminium is known for its dedication to providing top-notch aluminum products. In the field of aluminum tubing. Their diverse selection covers a range of aluminum pipes and tubes, in grades and specifications to meet the needs of sectors like construction,,automotive, and aerospace. They offer alloy bars, aluminum coils, and pipes as part of their product lineup; they also create custom solutions that adhere to industry standards such, as ASTM and JIS.

Xihui Aluminium’s impressive range of abilities is deeply connected to its state-of-the-art manufacturing plants that utilize methods, like cold rolling processes for production purposes. These techniques enable them to offer an array of customization options in terms of sizes and material specifications tailored to meet the needs outlined by their customers. As a consequence of this approach, Xihui not only enhances its standing as a provider but also underscores its commitment to sustainability by ensuring that its goods play a part, in creating efficient and eco-friendly designs.

Xihui Aluminum stands out in the aluminum tubing market due, to its emphasis on innovation and commitment to ensuring top-notch quality standards in every product they offer. They take pride in providing a range of aluminum tubing options. From ones to custom solutions designed for specific needs. This dedication, to delivering high-quality aluminum materials that adhere to strict standards empowers engineers and manufacturers to create efficient designs that align with industry norms.

The core of Xihui Aluminum’s product range lies in its selection of alloys, for their product manufacturing process. The utilization of alloy mixtures enables the company to create tubes tailored to meet mechanical requirements for applications that require high-performance standards. In response to the growing need, for durable materials Xihui persists in exploring ideas and providing inventive solutions that redefine the applications of aluminum tubing.

How Xihui Aluminium Maintains Superior Standards in Tubing Production

At Xihui Aluminium Company, we place a strong emphasis on producing high-quality tubing by implementing rigorous quality control practices throughout the entire manufacturing process. Our objective is to uphold industry-leading standards by carefully selecting materials and conducting thorough inspections of the final products. Our skilled staff and advanced technology usage at every stage of production ensure that our aluminum tubing consistently exceeds customer satisfaction.

Furthermore, Xihui Aluminium is committed to investing in research and development efforts aimed at enhancing the performance of its products. This commitment enables the company to improve its manufacturing processes, resulting in products that excel in terms of strength, resistance to corrosion, and overall longevity. The company also conducts testing and validation against industry standards to ensure the quality of Xihui’s aluminum products.

Xihui places a high priority on the quality of its products and ensures that clients have access to detailed product information to make informed decisions about the best aluminum tubing for their specific needs and applications. This transparency helps build trust and supports Xihui’s goal of fostering lasting relationships with its customers.